Utilisation optimised of the machines of cabezal mobile for the mechanised of medical components

Christer Richt, technical editor of

From the point of view of the mechanised of small pieces, the mechanised of medical pieces is usually different. The batches are used to to be smaller, with time of delivery more reduced, and material and designs more demanding. Likewise, to achieve some satisfactory results, the tools and the methods have to adjust to the characteristics of the component, as in the long and thin screws of titanium. Thus, they require complete solutions, with the tools and the correct knowledges, that take in consideration from the edge of cut until the subjection and the change of the tools.

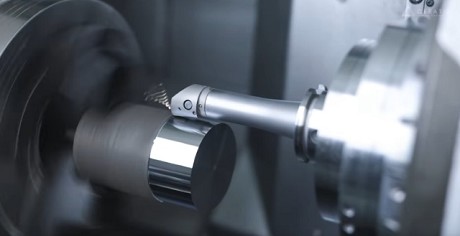

These solutions are especially important to guarantee a high efficiency of the machine of cabezal mobile multifuncional. Here, it is fundamental to prioritise no only the process of cutting but also the part of the no devoted cycle to the cut, for maximizar the results during the time of available production. For this, has to take into account from the length of the cut until the number of operations that have to realizar and the necessary time for the change of tools. It requires a systematic approach that identify the necessary operations, minimise them and group them to guarantee some cycles the most reduced and possible insurance. For example, begin with the taladrado and the inner turning in the husillo main and, applying all the depth of cut in a past, carry out the mechanised reverse, etc. in the husillo secondary, leaving the husillo main free, to mechanise other characteristics of the piece serves to establish, test and apply the most indicated solutions and appropriate for the production with a suitable support.

The mechanised of some medical components that they can manufacture in machines of cabezal mobile (like dental screws, dare you and vertebral) has been optimised to reach new levels of efficiency. In this area, the batches vary considerably, being able to comprise of thirty to one thousand or more pieces; which does that the time of change and of adjustment of the tools influence a lot in the economy of mechanised. In the mechanised of medical pieces, the tools of fast change mark a clear difference in the stops of the machine, especially, in batches of small to average.

To continuation describe three medical components typical manufactured in machines of cabezal mobile with examples of operations of mechanised and modern solutions that optimise the mechanised and mark a clear difference regarding productivity.

Tronillos Of titanium

The dental screws of titanium, already have a uniform or conical diameter, need, for some operations, an adapter portapinzas special for the husillo secondary. These include the external turning, the turning of threads, the milling, the tronzado, the taladrado and the mandrinado. The external turning is one of the first operations of semiacabado and has to be a very effective process, sure and consistent, able of sobreponerse to any problem of useful life and of break of the tool.

One of the challenges of the external turning of the screws of titanium is to achieve a wear of controllable tool and contínuo. And, at the same time that it achieves this, keep a line of the edge that guarantee the necessary superficial quality and a consistent precision, as well as the absence of rebabas. The speed of advance, in relation with the radius of tip, is key to minimise the superficial deviations: a too low advance can generate an unsuitable superficial finishing and an excessive advance can generate cusps in the surface. The geometry wiper can tend to generate strengths of excessive cutting in the screws, by what the form of the radius of tip and the geometry of the plaquita are fundamental factors for the performance. Likewise, it is important to loan attention to the control of the shaving in the turning of titanium, to achieve an action of cut without complications and a good evacuation of the shaving. A plaquita smaller and of positive basic form for operations of half turning is the ideal election to minimise the tendency to the vibration along the long body of the screw. The geometry of the plaquita of style UM is the first election for an application like this, since it offers an extensive area for the break of the shaving in different types of material, inluido the titanium. The edge of cut of a plaquita of style D will delete the shavings of the component turning and, with a depth of cut of around 0,3 mm, will generate a ready piece for the turning of threads in the machine of cabezal mobile.

With the end to guarantee a good level of productivity, has to achieve a speed of cutting the sufficiently high for the turning. The election of the quality of the plaquita is, therefore, important and has to be specific for the material of the piece. In this case, with the plaquitas acute positive, the plaquita has to have of a fine coating of PVD in a sustrato of plaquita hard of fine grain. The hardness in hot, together with a high resistance to the plastic deformation, are indispensable qualities. The quality GC1105 has been developed specifically for the requirements of the superaleaciones, so much of the titanium as of the stainless steel, since it confers a high performance to the acute edges and can apply with speeds of 80 m / min for the dental screws of titanium. A plaquita special without coating like the H13To, with the suitable balance between resistance to the abrasive wear and tenacity for the titanium, is used to to be a good election for the mechanised of dental implants thanks to that conserves his acute edge of cutting.

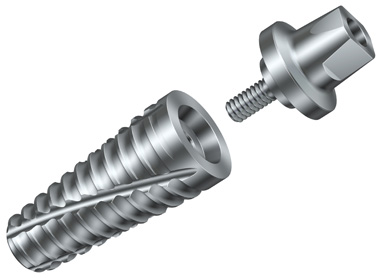

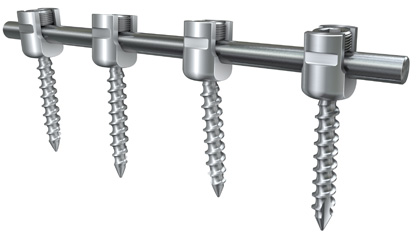

Osseous screws

These screws also are long and thin pieces of titanium done in a lot of different sizes, whose good subjection in the husillo secondary is essential to guarantee a satisfactory performance. Facts in variable batches, the thread of the screw is the main characteristic to take into account for the optimisation of the mechanised. The process of mechanised of the thread has to be safe, resulting in threads with a good superficial finishing and a good dimensional precision. A good control of the shaving is essential for the success. Ideal for these pieces is a modern machine of cabezal mobile, instrumented with a unit of threaded by eddy, a husillo secondary special and the capacity of supply of refrigerante of high pressesure that allow the turning, the milling and the threaded by eddy.

The threaded by eddy is a productive and reliable process that produces threads of big quality. This process avoids the tendency to the flexión and to the vibration. A good selection of the tools, the data of cut, the programming and the adjustment of the process are important to achieve good results, but the productivity is more important still. The advantages of the use of a strawberry of several edges, as in the threaded by eddy, when mechanising the increasing quantities of components for screws, as in the medical industry, are multiple.

The threaded by eddy is a process of mechanised tangential of several edges and, as such, involves edges of safe cut subjects to mechanical and thermal sensors loads moderate. The shortest shavings also are another advantage (often a problem in the past of turning of threads longer), as it is it the need of an only past in front of the multiple necessary in the turning of threads. Given the vicinity of the tool to the support of the piece of work in the husillo of the machine, the stability of the long pieces of work is an integrated concept in the threaded by eddy. Nowadays, the threaded by eddy is a very reliable process, extremely productive and produces good results in demanding materials. The concept of threaded by eddy of CoroMill 325 is a good solution for the optimisation of this process in the machines of cabezal mobile.

Heads of tulipa

The heads of tulipa used to connect the screws to a wand, like part of the destined components to the vertebral surgery, generally are done of titanium and require several operations. They are ideal pieces for the machines of cabezal mobile modern, done of material laminado through operations of turning, milling and taladrado. One of the greater challenges, in addition to achieving a mechanised competitive, is the rebaba. In this case, the milling is the method of mechanised dominant to arrive to the configuration of the head and requires of an accurate optimisation.

The slot so that it happen the wand has to be milling and characterises for requiring a depth of irregular cutting, for tending to the flexión of the tool and by the potential learning of rebabas in the inner thread of the screw. The combination of the strawberry and the route of the tool are decisive for the efficiency and the hygiene. A strawberry of ranurar enteriza of hard metal CoroMill Plura, with square form and radio of tip, in a quality indicated for the titanium, like the most universal quality GC1620 and GC1640, is the best solution for operations more demanding, as when mechanising in unstable conditions. The slot can mill in three past, generating the last part of the slot entering the strawberry of ranurar until the centre of the piece, deleting the shaving, when withdrawing the tool. The sides of the head of tulipa subject to milling lateral, with a blur radial of the strawberry of ranurar to realizar the radius of the piece. To guarantee a good hygiene, the chaveteros have to mill using the quality GC1640. The program CoroCut XS provides solutions for the operations of turning, turning of threads and ranurado necessary for the heads of tulipa. For a piece like this, that comprises a long screw joined to a head, a machine of cabezal mobile modern can be very advantageous, resulting in a good economy of manufacture.

Turning of titanium

This type of turning supposes a challenge regarding the control of the shaving. The long and continued difficult shavings to break can be a problem for the operational hygiene of the machine of cabezal mobile. The use of refrigerante of high pressesure, applied with the technology advanced of filters, improvement considerably the capacity to break and delete the shaving. Even to lower pressesures, the results of the streams of refrigerante very directed are very positive. The standard concept of CoroTurn HP, for the operations of inner and external turning, has of the technology of fixed filter with streams laminares parallel of high speed, precisely headed to the key points of the plaquita. Thanks to the fixed adjustment and optimised of the stream, his precision and his properties affect to the form in that it generates the shaving.

Tools of fast change

Are an indispensable part for maximizar the utilisation of the majority of the machines-tools, in addition to the optimisation of the times of cutting. The tools of fast change minimise the times of stop of the machine and are, therefore, essential to take out the maximum split to each minute of work in the machine of cabezal mobile. The system of subjection QS offers changes and fast and simple adjustments of the tools of cutting. The tools can enter and take out quickly of the machine, and can fix in the central line, optimising like this the repetibilidad and the precision through a safe positioning in the place of tools.

This system consists of a series of topes, coin and tool holders short that substitute to the accessories of the place of conventional tools. The edge of cut is very positioned, when the tool holders short is fixed against the tope. Likewise, you coin them of subjection by spring ensure the tool holders to facilitate the handle of the tool. The exchange of the plaquita reduces to a third of the necessary time for the conventional subjection in the machines of cabezal mobile. Likewise, the system of subjection QS also can combine with refrigerante of high pressesure for the operations of turning.