New biomaterial porous of titanium

Víctor Primo Capella (1,2), Carolina Ávila Carrasco (2,1), José Antonio Calero Martínez (3), Sergio García David (4), Iñigo Braceras Izaguirre (5) and Carlos Atienza Vicente (2,1)

1 Group of Sanitary ware Technology of the IBV, Ciber of Bioingeniería, Biomateriales and Nanomedicina (Ciber-BBN)

2 Institute of Biomecánica of Valencia

3 business Group LOVE

4 Surgival (Group Sewed)

5 Technological Corporation Tecnalia

In the frame of this project, the business group

Introduction

The Institute of Biomecánica (IBV), in collaboration with centres of investigation and with companies of the sector of sanitary ware products, participated in the project Cenit Intelimplant, that had like aim investigate and develop new biomateriales and surfaces nanoestructuradas and bioactivas with innovative properties and differentiated to structural and functional level regarding the current materials for his application in engineering tisular, biotribología and monitoring of systems implanted.

Inside this big project, the company LOVE, specialist in the manufacture of metallic pieces by methods pulvimetalúrgicos, and the Valencian company Surgival, specialised in the manufacture, commercialisation and distribution of implants and instrumental for Surgery Ortopédica and Traumatológica, posed like challenge the development and characterisation of a new biomaterial porous metallic for his use in implants that no only had some properties biomecánicas own of the osseous fabric, but it also had a suitable biological interaction that guaranteeed his biocompatibilidad and the growth again osseous fabric in his interior (osteointegración). This new biomaterial would allocate to the manufacture of boxes intersomáticas for the treatment of pathologies of vertebral column, where is necessary to keep the space intersomático and attain the fusion of the two vertebral bodies to ensure his correct positioning and the fixation of the implant respectively.

In the actuality exists a big variety of boxes intersomáticas, in his elder splits manufactured from metallic materials (titanium, alloys of titanium and foams of tantalum) and of plastic materials (PEEK) and with distinct designs to optimise the transfer of loads between the vertebral bodies. In spite of this variety in biomateriales and design follow being presents two important problems; on the one hand, the differences between the mechanical properties of the biomaterial used for manufacture of the implants and the ones of the osseous fabric, that can derive in what it knows how the sinking of the implant in the vertebrae; and, by another, the drop or invalid capacity of osteointegración of the implants, that can derive in an unsuitable fixation of the implant in the zone of placing.

To face this challenge, the companies had the collaboration of the Technological Corporation Tecnalia in the phases of development of the material and with the collaboration of the IBV in the phases of mechanical and biological characterisation of the biomateriales developed and of the implant.

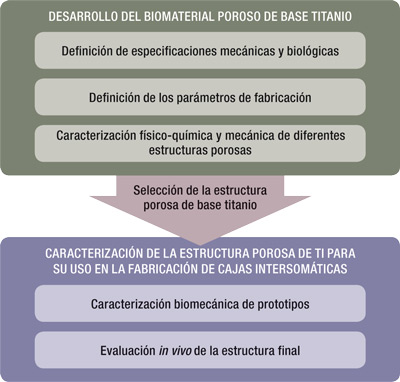

Development of the project

The development of project divided in two big phases (Figure 1). In a first phase established the mechanical and biological requirements that had to fulfil the new biomaterial for his application in a box intersomática lumbar. In addition to a good mechanical resistance, the same or upper to the one of the bone trabecular vertebral, required a material of low elastic module, the nearest possible to the of the bone trabecular. Likewise, it required a good resistance to the fatigue. On the other hand, they established the requirements of porosidad and size of pore to allow the growth of the osseous fabric in the interior of the material, that is to say, his osteointegración.

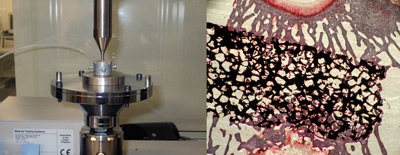

After the definition of requests, the technologies pulvimetalúrgicas developed were optimised and applied for the obtaining of 5 structures of foams of titanium (3 with a high degree of porosidad and 2 with a low degree of porosidad). The samples obtained were characterised physical-chemical and mecánicamente with the aim to evaluate the fulfillment of the clear-cut requests. The mechanical characterisation was realised in the IBV and based in the mechanical analysis of the samples by means of essays of traction, compressesion and flexión to three points. Like result, defined the parameters of manufacture and selected the structure that better adjusted to the marked specifications to the start of project and that, therefore, would offer the best characteristic for his use in the manufacture of boxes intersomáticas for fusion in lumbar column.

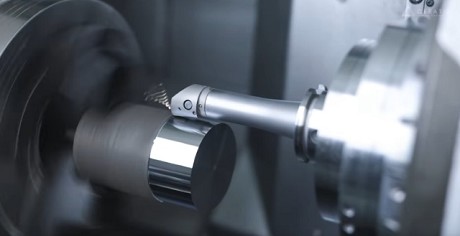

This new structure was the one who used to llevar the second phase of the project, that centred in the evaluation biomecánica of demostradores manufactured from the new structure (Figure 2) and in the evaluation in alive of the same in animals of experimentation.

In the evaluation biomecánica of the experimental models characterised the mechanical behaviour of the boxes intersomáticas lumbar of porous titanium in front of different mechanical essays normalised: static loads and loads of fatigue.

Regarding the biological evaluation, llevar the implantation in alive of samples of the foam of titanium developed with the aim to evaluate the capacity of osteointegración of the same in alive fabric. For this used the experimental model of implantation in condyle femoral of rabbit. From the samples obtained of the study in alive, llevar the studies of osteointegración, that consisted in a mechanical study of the necessary strength to extract the implants once osteointegrados (mechanical essays of push-out) and in a study histológico of the growth of osseous fabric in the interior of the structure (Figure 3).

Results and conclusion

The experimental model manufactured from the new foam of titanium presents a mechanical behaviour very near to the bone trabecular, one of the main requirements of the project, presenting a resistance to compressesion more than sufficient for his operation like implant intersomático for lumbar fusions. Besides, it fits to stand out that the boxes of porous titanium have a mechanical behaviour to compressesion and sharp nearer to the of the boxes of PEEK (current material of reference in the manufacture of implants intervertebrales) that the boxes of titanium macizo.

Regarding the capacity of osteointegración of the new foam of titanium, the mechanical essays of extraction equipment equipment indicate that the resistance of this material is upper to the values of resistance to the extraction equipment equipment of other porous metallic materials or with porous coating evaluated in studies published of osteointegración. Regarding the study histomorfométrico, fits to stand out the presence of a significant quantity of osseous fabric in the interior of the implant, so much to level more superficial (27% of the porosidad external occupied by osseous fabric) as to level deeper (14% of the porosidad inner occupied by osseous fabric). Besides, it does not observe any adverse answer in the fabric around the zone of implantation.

By all this, can conclude that the new metallic material porous developed by the companies LOVE and Surgival, in collaboration with the Technological Corporation Tecnalia and the Institute of Biomecánica, fulfils with the mechanical and biological requirements defined in the project for his use like biomaterial for the manufacture of boxes intersomáticas lumbar, being therefore a good starting point for the development of a new generation of implants of lumbar column.

Gratitudes

The project Cenit Intelimplant (Biomateriales Advanced for a New Generation of Implants) led by BTI (Biotechnology Institute, S.L.) It was one of the 16 projects approved by the Centre for Industrial Technology Development (CDTI) in the third announcement of the program Cenit, that inscribes in the initiative of the Spanish government Wit 2010.