Machining, measure and improve: efficiency and quality

October 14, 2010

What suggested us the idea of increasing the productivity and reduce costs? Think of it, would produce more cheaply, with what could lower prices, without buying new equipment and without increasing the labour force. It seems the less desirable. However, we would be Additionally, reducing the cost. Part of the savings achieved can devote to fund the improvement and innovation, now we would be coming free. This approach would lead to continuous improvement, because by investing, for example, in devices that make more agile the changes of tools, we managed to again increase the productivity and return to the beginning of the cycle of savings.

This seems clear, but how can a workshop of machining get that initial productivity growth? The excellent results obtained in the sector companies advise applying Lean Manufacturing methodology.

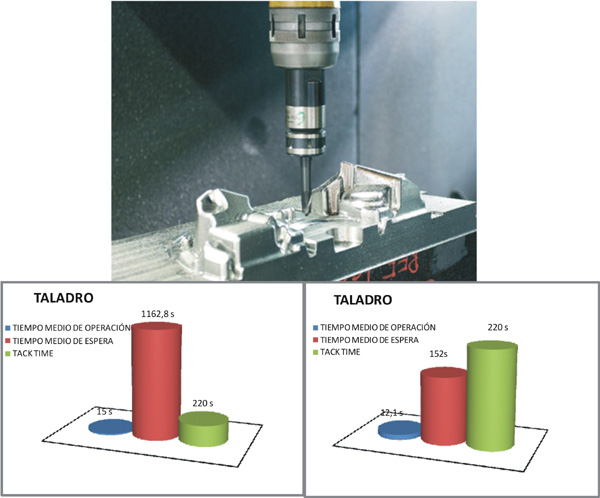

The key aspect is to think about what our customers mean by value of the products that we offer and eliminate all those tasks which do not provide value in our processes. In general, our customers value the pieces of high quality (mechanized with the specified tolerances, good finish, etc.) and delivered in time. Few things are of importance for him. So we must eliminate unnecessary transports, retrabajos and above all, time of waiting between operations. This point is key. Although our workshop apparently works at a good pace, a more in-depth study of the distribution of time can bring surprising results, being frequent finding of machining processes in which the total waiting time of the pieces between the different operations reaches 80% of the total time of operation. It is imperative, therefore, measure and analyze the times of all operations and all expectations.

Waiting times are obstacles that must be eliminated or reduced to ensure a continuous flow.

To achieve our goal of eliminating waiting times we will have the following tools:

Reduce the volume of pieces that we transfer of an operation to another. If we work with small packet queues will be small and waiting times also, avoiding bottlenecks.

Reduce the size of the lot we mechanize. If we produce large batches we run the risk of incurring further losses if the customer changes their specifications and have high inventories of intermediates or final. We will have to optimize the size of the lot, taking into account changes of tools times.

Redistribute the sequence of operations to the extent possible, improving, and distributing operations slower to reduce waiting times and bottlenecks.

Work at the optimal pace. Contrary to what one might think, the proper pace of production is not the highest we can get, but that allows us to meet the demand. If our demand is 100 pieces a day, our day of 8 hours (480 minutes), we fabricaremos on an ongoing basis a product every 4.5 minutes, so we get 106 pieces, if one is defective.

Machining faster of what the client requested involves overproduction and, among other, costs of storage. In addition, if the care in which each operation is carried out as quickly as possible is it will make probably coast of penalising the quality and incur costs of rework of pieces. It is appropriate, on the other hand, machining each piece at a time to meet the demand, is the ' tack - time'. We will have to put much care in its correct calculation and keep the time of each transaction below that value.

Levelling time of occupation of operators to achieve a uniform flow of parts and reduce waiting times.

As a summary of all of the above, we could say that what we do is measure and improve our processes to achieve efficiency and quality in our products.

It is important to consider that if the Lean Manufacturing is well applied not it may fail, because by eliminating delays and obstacles always improve our processes and initial savings invested in continuous improvement. In fact the average of the improvements made in 40 companies which have implemented Lean, according to a survey conducted by the NIST (National Institute for standards and Technology, USA) is as follows:

| PARAMETER | RESULT |

| REDUCTION OF DELIVERY TIMES | 90 % |

| INCREASE OF PRODUCTIVITY | 50 % |

| IMPROVEMENT OF THE QUALITY | 80 % |

| REDUCTION OF SPACE USED | 75 % |

Given that the first improvements can be achieved in a short time and without additional investment does not worth testing?