Value added in production for the aerospace sector

October 14, 2010

What do we mean by added value?

Before the advent of the computer science and information management systems stated that it generated a kilo of role of associated documentation for each kilogram of material that was sent into space. This phrase describes quite graphically the importance in the aerospace sector of the generation and management of productive activities and those associated information.

The extensive information systems use has not at all relaxed these requirements, but rather on the contrary, demanding of suppliers not only large amount of information support, but in many cases that is given in a proper format.

The aerospace sector based their high standard of quality in production on two main pillars; independent each other and in turn closely linked and both indispensable. One of these pillars is the quality of the parts themselves, which is alleged in this forum. The other pillar is the robustness of the processes through the implementation of verified and tested procedures to ensure the repeatability of the results and make them more independent of the variability inherent to the intervention of the people.

We can summarise this statement saying that it is not enough to be good, but that should prove it and written by the application of robust procedures and systematic registration of activities and actions. Is why every piece we produce, every system we developed, must be accompanied by documentation support, at any level of the supply chain.

The essential for the transmission of information concerning the production of a piece is the level of manufacturing, of all known. This invention of the 13th century has remained more or less the same in structure and approach over the centuries until the last few decades. The irruption of CAD/CAM/CAE systems first led to the demise of the paper support, and later an new design philosophy based on 3D models.

In any case, either through a traditional-style or a model plane, through such vehicles usually convey information relating to the dimensions, tolerances, material base, surface finishes, etc. However, there are a number of requirements which are not transmitted through the level of manufacturing. These requirements not included in the map or model are those who want to cover under the name of 'value added in production'.

What requirements are these?

The requirements which we are talking about; their knowledge and capacity for implementation, is what distinguishes the holders of certain 'aerospace culture' of those who do not.

Spanish industrial fabric, and in particular that of the community of Madrid, can pride itself on having among its members to several examples of workshops that have succeeded in implementing in their organizations 'aerospace culture' which is a toll of entry that must be met to join this club.

Possession of this culture allows the manufacturer not only understand these requirements, but even the knowledge that must be respected them but she has not been made explicit reference to them at the levels of manufacture.

Traceability (*)

The keeping and the maintenance of traceability is one of the first requirements that must be taken into account in the life cycle of the production of a piece, as it affects from the supply of the base material. Our organizations must have the media in order to ensure not only that the material is specified (requirement that appears in levels), but we can also identify what lot of supply, or even what casting, comes from the material of a piece in particular (a requirement that will not normally appear in levels). In this way, and not another, we can extrapolate the results of any tests metallographic that we would do to a specimen of the consignment to the characteristics of the piece in manufacturing.

Information on the batch of supply, therefore it has to be somehow linked to the documentation associated with the piece of manufacture through the application of any procedure of our Organization. We must be able to manage this information, preserve it for years, and transmit it to your customer if so required. The use of a system of production and logistics management much easier this task, even allowing remote queries for those customers whose importance is such that we are interested in access to our system.

(*) According to the DRAE 'Trazabilidad'

- Possibility of identifying the origin and the different stages of a process of production and distribution of goods of consumption.

- Documental reflection of these stages.

Calibration and certification

As important as making a measure is to ensure that the measurement instrumentation is in perfect state of calibration.

We must have in the average minimum metrological organization to ensure the quality of our work. However, we can or not available within the Organization of the necessary means for calibration or verification of our media metrology.

Each workshop can choose outsourcing policy (or any policy of outsourcing that most suits their possibilities and specific problem). In any case, well, let's do all the calibrations internally, either make them partially or completely outside of our Organization, we must establish a strict policy of calibrations; with a proper record of all documentation generated in these proceedings.

Change control

The change is inherent in our reality. We all live in a quasi permanent state of change in which the product that leaves our facilities never (or hardly ever) is exactly the same that was defined at the start of production.

The orderly and systematic introduction of changes in our production is a differentiating element showing the possession of that certain 'culture Aeronautics' that we mentioned previously. A change is a document, the same level as the plane or model that we manufacture the piece. As such a document must have a reference; and this reference should be attached in the documentation of manufacturing that is used and generated in the production of the piece. Through the orderly introduction of these changes our State of the (build standard) configuration changes of the State 'as designed' the State 'as built', with which we deliver the piece.

Fortunately for the system, many the machining centres which have already internalized in their organizations this culture. This mode of action has to be apply not only to the h/w to produce, but also everything that is in intimate contact with this; tooling, w of programming of the machinery, etc.

Certification of persons

A recurring issue in audits of large contractors and system is as follows: "How are confident that the person which has been given a job is qualified to make this work?". In small organizations in which there is a division of labour will be sufficient to be in possession of the necessary certifications to run the job.

However, in larger organizations which already if there is a specialization of labour must document what training requirements should be to carry out a work, and cross this information with personal certifications of each operator. These certifications can be externally or through internal training plans.

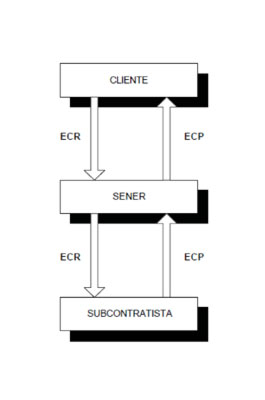

Transfer of requirements

So far we have analysed how they respected certain requirements that we have referred to as 'added value' to not appear typically in the basic documentation of manufacturing in our Organization and working methods.

In the background, throughout these paragraphs, we have been analyzing how the system transmitted their requirements towards - in this case - the machining centers, and we have briefly described what documentary evidence is expected as guarantors of these requirements.

The system have received in the large main contractors turn their sets of requirements, which have been taken which are application - in this case - for the production of mechanical parts.

The chain of transmission of requirements should not end at this point; the system we hope and demand that an efficient interpretation, collection and transmission of requirements exists at the level of the machining centers provided that they outsource a process.

Language

Finally we will make a small mention of the eternal pending of the Spanish education system: the languages, and in particular English. The aerospace sector is heavily colonized by the Anglo-Saxon culture; the vast majority of the generated documentation will be in English; and we should be able to generate also - on demand - our documentation in that language.

Not being able to communicate in English limited our capacity for growth and access to these markets.

Conclusion

Throughout these paragraphs we have reviewed the existence and importance of some requirements that in the eyes of some can be very basic, but the reality tells us that not all of them met today in all the machining centres with whom we come into contact.

The topics described here do not constitute an exhaustive list, but the level of compliance with them if they are for a sistemista as Sener a first indicator of what a difference a good workshop of a good workshop capable of working with guarantees in the aerospace sector.

However, we do not want to leave the impression that this is an insurmountable issue. At all, and in this respect and as part of our commitment to society, Sener will be always ready to help in the best of our ability to disseminate this knowledge resulting in the end only for the benefit of all generating an industrial fabric more competitive and more capable in a sector as claimant and such internationally as the aerospace.