The third edition surpassed the participation of the above

Meetings of the machining: after Madrid and Seville, Vitoria confirms his consecration

April 7, 2010

The meetings of the machining held its third edition in Vitoria and demonstrated the success of the formula with a higher than the previous two stake. The good acceptance among professionals of the sector is due to the concept itself of the event, which brings together institutions, companies tractors and small and medium enterprises of machining that meet the common objective of increasing the competitiveness of the network of subcontracting in the tooling. These encounters are possible thanks to the impetus of sponsoring undertakings, sensitized to the need to generate activities that improve the competitiveness of the industrial sector of subcontracting by machining in this country. Companies that have decided to create an extra added value in their environment because they are aware of the urgency involved.

The meetings of the machining want to contribute your bit in the improvement of the competitiveness of the Spanish mechanizers. They are the lowers of the machining, the palpable demonstration that from the sector itself can cause situations to achieve greater collaboration between the companies. Because, as said Fidel Gomez, of the House of Álava, "is it over the time of the comfort, but the time of the opportunity remains open".

The good, if brief, twice as good

As on previous occasions, following the relevant presentations by Ramiro Bengochea, CEO of WNT, given beginning to a series of presentations aimed expressly at the auxiliary industry of machining sector. That is, when for example María Delgado, of the Department of coordination and stimulation of the CDTI exhibited the possibilities that this agency makes available to SMEs, it did so precisely thinking in them, companies usually have the feeling not to reach such institutional aid. And the truth is that he had a relative success given that in the ensuing discussion, moderated by Ángel Hernández (Interempresas) were put on the table the difficulties of access to aid and, especially, the problem of time in which this aid are madegenerally, in the view of several participants, too late. Conclusion to the spoken in Vitoria, one could say that when a company requires financial support to carry out a technologically innovative performance, with a high component of risk, the money should reach before their hands, precisely in order to address this project.

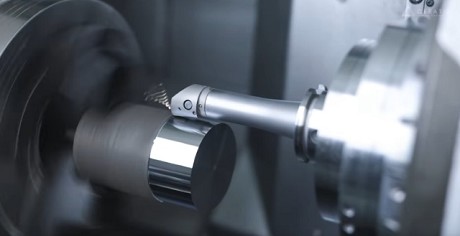

Who spoke the language of the SME machining was Roberto Hernando, Manager of the Intermaher-Mazak who exposed the advantages of working with multi-tasking machines: reduction in 90% of the period of gathering raw, 20% less in cost of material75% less stock of material, a 92% reduction in the time of change of piece, a cycle time 29% more short, deletion (virtually) of time between operations, smaller size of the cell (6 machines to 2 in the example set out in the day) and rapid development of prototypes.

In this sense, during the ensuing discussion was an enriching exchange of views on the multi-tasking machines. A participant spoke of little use in machining of multi-tasking machine workshops. In his view, the workshops of machining of the Basque country are very well equipped but there are very few machines used to 100%. "I see very little technological implementation - he said-". We must aim to optimize resources rather than to make major investments. One of the problems that we suffer is that we have very little technological culture. "We are aware that equipped is important but not so much that we have to optimize what we have". The comment was directed at Roberto Hernando, who agreed with the fact that a machine multi-tasking, by itself, does not solve anything. "Effectively - said - he hit in machining, the developments following the acquisition of a machine that provides a technological leap, depends on a set of circumstances: must have efficient machines, give them a proper use, using innovative and tools adapted to the task in question"adopt appropriate machining strategy and the Organization of the workshop. We, at Intermaher, also visited many companies and we see everything: from which has made great strides to which continues the same as always. "But I have to say that most commonly is that those who acquire a multitasking machine are very satisfied with it and his performance".

José Antonio Gómez Vadillo, also was of the view that we have a very well equipped workshops. However, in his view, the mecanizador has to improve in the sale. "You have to visit more customer, strengthening the sale by repetition and loyalty." We also begin to draw doors and improve the image, because the Chinese sold per image, with a catalogue and a website. And we do not know to sell our capabilities. "We are not a country vendor, we are workers, and high-cost".

It must improve the use of the tools

One of the first questions of the debate was to Ramiro Bengochea, main driving force behind these encounters and ultimate responsibility of WNT. Can we assist to a revolutionary change in the tools? Negative, revolutions do not already exist and all developments are progressive. Ramiro Bengochea said that the main improvements will come through a combination of good technology and good service. The response supplemented her Oscar Gonzalo, the technology centre Tekniker, who brought an important fact: only by 30% of the time used the tools properly. I.e., the improvement in the use of the tools must begin here and much to reach 100% of use of tools whose materials and geometries are being constantly studies and developments from the manufacturers.

A varied programme of talks

After the presentation of Intermaher took the word Melcior Soler, Tecnocim, with the aim of exposing what should be the Organization's system of the CNC programming in a workshop for the manufacture of parts in series short and varied. He said, the organizational system of the CNC programming that implant should be integrated into the digital organization of the company and must be oriented to obtain traceability of machining processes and ensure the possibility of analyzing the processes carried outrepeat them when necessary and/or update them quickly, after changes in some of its aspects. You must also allow applying customizations in the CAD CAM system to optimize, speed up and give security to the programming of the repetitive work. To meet these premises is must take the definition of the parts to be manufactured in format CAD drawn to scale, make processes and programs of machining by a CAM system that part of the information in CAD format and not schedule or make changes to foot machine which undermine the information generated in the CAM.

After Melcior Soler, Maria Delgado Álvarez, of the Department of coordination and promotion of management of technology, took the floor with his presentation entitled 'Financing of innovation and enterprise development'. Followed the presentations of Fidel Gomez, of the House of Álava, on the internationalization of SMEs, the entitled ' the right choice of the fluid of mechanized vs. productivity improvement ' (BP) and the José Antonio Gómez Vadillo on machining and management, which, as the morning with their examples and data in meetings in Seville, enliven (see full article in the February issue of Interempresas)(, page 43). The presentation 'New trends for machining', Oscar Gonzalo, researcher of the Department of manufacturing processes of Tekniker - IK4 was also highly valued. He spoke of non-conventional processes of machining as the laser machining and machining at high speed, Rotary machining by ultrasonic and electrochemical machining and, in a second block of the submission, in the processes of machining swarf removal: hard, process simulation machining and machining assisted.

Look to the future

The machining often perceive the activity of some technological centres as something away from them. However, this is not necessarily the case and the future is often already present. Oscar Gonzalo said that currently the manufacture by chip startup focuses on obtaining products of higher value added and quality costs and reduced times in increasingly demanding materials, which should improve the performance and quality.

Among the various technologies put laser machining is a reality now available. With this technique, laser radiation causes a warming progressive, reaching the temperature of melting and evaporation of the material in the material. This evaporation results in a micro-machining of precision in the area of action of the laser.

Can you machine for ITP?

The 'big' had the time. Plácido Rodal, responsible for manufacturing technology of ITP was the subject of numerous questions during the debate, after the paper entitled 'Manufacturing' for the LPT ('Low Pressure Turbine'). Components that ITP manufactures for Aeronautics are the shells of these modules of the turbines, bearings supporting structures, discs, fixed blades and other sub-components. In short, there are many machining operations in game, from the milling, turning or grinding, passing through the brochado or boring, until the EDM, as well as other many processes such as welding, heat treatments, coatings, etc. ITP does everything, subcontracts and that was precisely the point of interest for the present, taking into account that the company needed an auxiliary industry, but the search all over the world. Plácido Rodal, the conversation about what kind of machining "serve" to ITP, it recognized that size matters and suggested collaboration between SMEs from machining to develop projects aimed at the major aeronautical companies.

The expectation of the presence of ITP was logical, taking into account the work of machining a company of this size can outsource. An of the questions revolved around the reliability of the forecasts made by large companies on the manufacture of aircraft in the next few years. The risk is high, which are long-term investments, while Plácido Rodal explained that this is a joint venture. As explained above, the risk of investment unfolds to the supply chain. Search "partners of risk", which leads to a waterfall to the base of the pyramid of supply. A client such as Rolls Royce is ITP required it be involved in the development of the pieces from the initial phase, with the risk that this entails, but with the reward of work guaranteed for a specified time. A similar model is the ITP is demanding their suppliers which, incidentally, ITP seeks without borders.

Another interesting topic for discussion: what strategy will continue to ITP, will rely on local machining? "Ten years ago had no doubts: apostábamos by the local supplier." But in the past seven years the company has changed and what the results are more important. Look with appreciation the close supplier, but do not give them what they do not give to others. The competition is open. There was a time that we stayed in a term means, the work of low-cost contratábamos them in low cost countries and cooperábamos with local suppliers in other developments, to give us benefits in the medium term. But the latest crisis has given another twist and already not we ourselves help anyone that does not risk it with us. We call on our suppliers as well as our clients to us: risk and cooperation in the development. We believe that the local machining are very good, but too small. "They are not agreed among themselves to grow and none wants to take enough risk."

In any case, work for or with ITP opportunities are there. An example is the cutting of the low pressure turbine discs. In them are semi turbine blades and move the gas that drives the aircraft. It is the most critical piece of the turbine of the aircraft. The measures of control of the raw material, machining and rest of your manufacturing processes are very high, because any defects that cause a breakdown of this piece in flight could cause the fall of the aircraft. Roughing of these discs is a type of work that this company does not consider high added value, but not low cost. "In fact it is a job that can provide us a powerful local mecanizador or a Smith who can deliver the mechanized forge." We'll bet by the most profitable for ITP. It is not inexpensive, but we must offer him the best 'wrapped' possible. "I think that there are still opportunities in this field."

Size Yes, 'savoir faire' also

For Plácido size matters, but is of the opinion that the proprietary technology remains a key that can change the rules of the size. "It also imports know doing so". An effort in innovation is forced to get exclusive processes and not wait for large companies to SMEs of the hand carry. "" We want to someone who already has technology.""

Small take advantage of the globalization

The presentation of Peter j. Carrillo, director of TAFSA, a company of machining of 16 workers in Madrid was highly regarded among the attendees, probably because most of them were reflected in the company. And sure, also, because in his paper Pedro Carrillo emphasized that the current conditions of global competition have no why be an obstacle to a company of this kind. There is the way to work in collaboration with the world of the 'low cost' for the solution that the client requests, and this concerns both the cost and the type of piece which is making. Simply, should lose the fear to get out. As simple as that.

The debate

In the discussion that followed the presentations, moderated by Ángel Hernández, head of Metal of Interempresas, were interesting topics that are of concern to the companies. Precisely, in the origin of the meetings is intended to create an atmosphere for the exchange of knowledge, but also the intention of interrelated companies which can complement in order that their companies grow through collaboration. The meetings should go card and an open mind to locate possible partners.

As an example of cooperation, Ramiro Bengochea gave the case of the meetings of machining in themselves. "This so have started companies that we think not only that we must improve our competitiveness but we must also promote it in our environment." I think that we ourselves are an example of cooperation. Jorge Rodríguez (Group Carinox), Roberto Hernando (Intermaher-Mazak), Melcior Soler (Tecnocim) and myself we have gathered to make promotion in a different way. This we are paying us because we have decided to innovate in the way of promoting companies. We believe that from this we improve the image you have of us, that we give more confidence, but also, on the other hand, I convey our conviction that only innovating and working together we can move forward. "This so we can fix us!"

Aid, who come from?

The idea that many institutional aid not reaching SMEs is widespread. Strong phrases were heard in the debate: "actually, I would say that the majority of SMEs or smell the aid for r & d, technological development, etc." People from SMEs when we are going to make an investment of innovation with technology we were outside. Access to subsidies is complex and we have never had time because we were concerned about generating wealth mecanizing, to be profitable. "I always have thought that I had to make money mecanizing pieces and not asking for aid, but now it is time to find money in every possible way".

In this same vein, an Assistant to encounters briefly exposed his case: "we created our company eight years ago and we have gone from 4 to 25 people." During the 8 years we have dedicated to work, to produce. Money has been made, he has worked at the top, but no one has been concerned about what we are talking about here. We do ask grants at the beginning, but we did a later next year, which helped us very little. "The workshops have few means to get involved in these matters".

As a counterpoint, he also spoke of SMEs that have Yes agreed to aid the CDTI.