WIS water injection screw compressors

January 21, 2008

Install filters on an installation with compressor lubrificado not always ensures that the system is completely free of contamination in the event of great contribution of oil or failure in the filtration system. Only oil-free compression technology can be guaranteed to 100 per cent the production of oil-free air. The WIS 40-75 series of Worthington is the perfect solution to meet these stringent requirements, thanks to the patented technology of injection of water, with the added benefit of a higher energy efficiency, and a wide range of models available. All meeting high standards of purity class (ISO 8573-1 class 0) which ensures that cannot exist traces of oil in the air network.

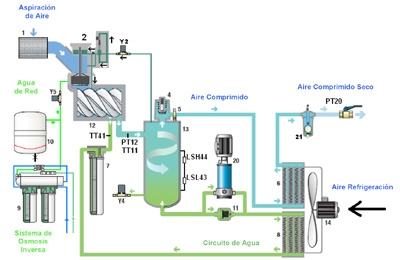

WIS technology replaces the water lubrication oil, sealing and cooling of compression element. Among other advantages, the compressed air is not contaminated with oil; no system of treatment of air (Prefilters or postfiltros) is not necessary to eliminate cargo loss and unnecessary energy consumption; and don't need any condensate treatment system.

Also, WIS compression is almost isothermal thanks to the injection of water allowing a cooling as a result and optimum a compression of high-performance.

This efficiency is increased with the addition of hydrostatic and hydrodynamic bearings without lubrication. These bearings are covered by a film of water pressure allowing a smooth sliding without friction.

An absolute quality of water

WIS equipment include a filtration system of reverse osmosis that allows injecting directly drinking water in the primary circuit network. Exempt from minerals and sediments, reverse osmosis water protects the circuit and prevents reproduction of bacteria.

Also, and in order to eliminate any risk of corrosion, all components of the WIS are designed using materials for that purpose as cross pottery, a crankcase alloy bronze/aluminium rotors, deposit of stainless steel and fittings and brass connections.

In order to adapt the WIS compressor to the needs of the client, the wide-ranging WIS is available in powers from 11 up to 55 kilowatts, flow rates from 109 up to 550 cubic metres per hour, with pressure of 7.5, 10, and 13 barin settings of cooling by water or air, with or without refrigerating dryer integrated, and optionally control of variable speed is available.