Solids system, un programa completo para cada precisión

23 de septiembre de 2009

Las ventajas competitivas de Solids system-technik en soluciones de dosificación y pesaje son:

- Alta precisión de dosificación

- Productividad de proceso

- Robustez del sistema

- Soluciones específicas y particulares

Básculas de pesaje para sólidos y líquidos

La marca dispone de una gran gama de básculas, enfocadas a las necesidades de cada cliente:

Bin Scale: Dosificación de cargas con tolvas báscula de metal directamente sobre células de pesaje.

Flex Scale: Básculas de tolva flexible, para pesaje de productos de mala fluidez y con tendencia a pegarse. Tolva elástica de goma especial y boca de descarga elástica e integral proporcionando un vaciado sin restos.

Tara Compensation Scale: Tolva báscula provista de compensación de tara, según necesidades, dispuesta directamente sobre células de carga o soporte de pesaje con un sistema de balances paralelos, que evitan vibraciones externas.

Diff Dos: Dosificación en continuo con básculas de dosificación diferencial. Mediante la utilización perfeccionada de la variación de la señal diferencial de báscula, se obtiene un caudal regulado y constante.

Vacu Scale: Combinación de tolva báscula con un sistema de transporte neumático y dosificación por vacío del producto. Especialmente adecuado para la preparación de cargas y/o composiciones.

Pressure Scale: Pulsor báscula, dispuesto en marco soporte que evita la interferencia de fuerzas externas. Apta para la formulación de cargas pesadas y su posterior transporte neumático y alimentación a mezcladores, reactores, disolvers, …

Giro Scale: Báscula de cubeta giratoria, que gira 180º para el completo vaciado. El diseño es muy compacto, obteniendo precisiones muy elevadas hasta ±1 gramo. Ideal para la dosificación de pequeños componentes, hasta 50 kilos.

En cuanto a básculas para líquidos, encontramos cabinas de dosificación de aceites; básculas tipo LSC de diseño compactas para una exacta dosificación; y básculas de aro tubular para la determinación de la densidad de los fluidos en el proceso.

Básculas de dosificación

Se integran en el sistema todo tipo de equipos de dosificación del mercado (sinfines, canales vibrantes, alveolares, …) y además se aporta un valor añadido diferencial con desarrollos propios, tales como:

- Dosificador rotativo: Ideal para extracción y dosificación de productos a granel. El cuerpo contiene un plato giratorio que evacua el material depositado sobre él, en mayor o menor grado, dependiendo de las regulaciones mecánicas que dispone: el ángulo de la rasqueta y la altura del cuello-talud. Además se dispone de un tercer parámetro de regulación a través de la variación de frecuencia del motor. También se puede disponer de un accesorio agitador, que favorece la extracción de producto. Con todo ello, se consigue un flujo de aporte de producto continuo, que da como resultado un control total de la dosificación y en consecuencia altas precisiones.

- Precisos: Dosificador de precisión, incluso con productos cohesivos, posibilitando una muy alta exactitud de dosificación, debido a su mecanismo de dosificación fina exenta de pulsaciones, consiguiendo así un flujo de aporte a la báscula constante y de forma continua. El grado de llenado uniforme de la espira, contribuye a la más alta precisión y constancia en la dosificación.

- Fine Dosing: Para dosificaciones de alta precisión (1 gr> 0,1 gr) se integran equipos de dosificación de sólidos en alta precisión con equipos basados tanto en el descuento de peso como en adición de peso. Estos equipos permiten poder automatizar y gestionar recetas donde participan componentes (conservantes, colorantes, aditivos, etc…) con una exigencia de precisión muy alta. Están diseñados para permitir una fácil limpieza y cumplen con los requerimientos de la industria alimentaria y farmacéutica.

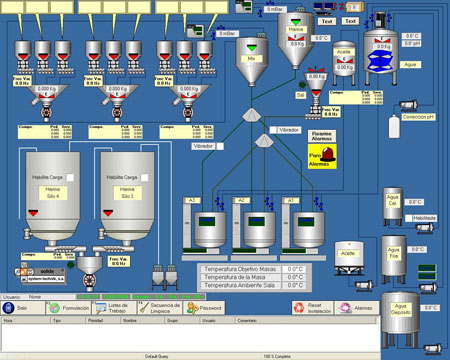

Sistemas de control

Es tan importante o más el sistema de control de dosificación y pesaje que se realiza, que la báscula y el equipo dosificador utilizado. Por ello, Solids system dispone de un departamento de automatización y visualización Scada, formado por especialistas en procesos de dosificación y pesaje. Estos sistemas permiten una visualización completa del proceso; la parametrización de elementos que intervienen en el proceso; la definición de fórmulas y órdenes de trabajo; generar datos históricos tanto de proceso como de alarmas; y la conectividad con una alta variedad de dispositivos.

En definitiva, permite mejorar la productividad; un mayor control de producción del proceso; una mejora del control de calidad, debido a la recogida de datos de planta; y la trazabilidad del proceso productivo.

Solids systems

La compañía, afincada en España en la localidad guipuzcoana de Zarautz, pertenece al grupo Solids solution group. Fundado en el año 1969 por H. J. Linder, solids solutions group con sus empresas asociadas solids system-technik S.L. y system-technik GmbH recopila más de 35 años de experiencia en el proyecto y realización de sistemas automáticos para la manipulación de productos a granel. Su actividad central es el almacenamiento, descarga de silos, transporte neumático, pesaje y dosificación, control y automatización.