Laniru comienza una nueva etapa en la subcontratación

Con unos 23 empleados, Laniru es una empresa con dos divisiones diferenciadas: una es la de máquinas, donde cuenta con máquinas de corte por láser, panelado, plegado, punzonado, corte por chorro de agua para grandes espesores de hasta 180 mm y diversos materiales, así como una máquina combinada, todas destinadas a la fabricación de elementos y subconjuntos. Dispone esta división también de una oficina técnica con sistemas CAD CAM. Los elementos producidos en la unidad de máquinas tienen dos destinos. Una parte de ellos se entregan a clientes y ellos lo ensamblan en sus producctos. La otra parte se destina a la otra división de Laniru, la de montaje y calderería, que cuenta además con una unidad de mecanizado, donde se fabrican y se preparan los componentes que necesitan los subconjuntos que posteriormente se ensamblan bien por soldadura, bien por encaje mecánico, y se pintan o se tratan superficialmente de diversas formas.

El año 2005 ha sido determinante en la evolución de Laniru, con la incorporación de nueva maquinaria de primer orden, “uno de nuestros principales valores diferenciadores”. A esto se añade la próxima certificación, que facilitará la aproximación a los sectores de producción en serie como la elevación, ingenierías e incluso automoción y la gestión adecuada de un crecimiento importante en los últimos meses. Es un proyecto que todavía se puede considerar en fase inicial y que en el 2006 dará ya plenos resultados a nuestros clientes.

“Destacaría la máquina por corte de chorro de agua —dice Alfonso Álvarez—, cuyo potencial para cortar grandes espesores es importante y que complementa la actividad de corte por láser, ya que éste tiene limitaciones para determinados materiales y espesores. En la unidad de máquinas contamos con los equipos óptimos para el sector al que nos dirigimos, con capacidad para grandes volúmenes, de hasta millones de piezas anuales en la unidad de máquinas, unas cantidades que se reducen en la unidad de calderería fina, donde se pueden entregar en torno a los 5.000 subconjuntos anuales”.

La idea en esta empresa guipuzcoana es clara. “Tenemos unos medios excelentes, un grupo humano capaz y motivado; estamos todavía en una fase de evolución en la subcontratación de la fabricación para diversos sectores. Queremos dar pasos sólidos”. Sin prisa, pero sin pausa, con pasos sólidos y que aseguren el éxito de cada una de las fases. Así, por el momento los tornos, centros de mecanizado o taladros, se utilizan actualmente exclusivamente para el mecanizado de piezas integradas en los conjuntos o subconjuntos que Laniru suministra y no para terceros”.

Nuevos sectores

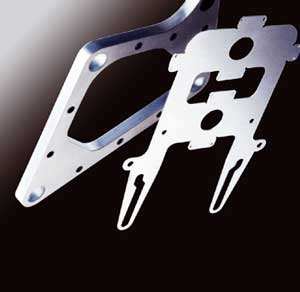

En el campo de la calderería fina, algunos productos típicos actualmente son paneles de mando, subcomponentes de máquinas o instalaciones de automatización, piezas de aspecto exterior, en todo tipo de materiales. La creación de células de montaje es una idea que se pretende para el futuro.

Algunos ejemplos en línea blanca, siempre en piezas metálicas paralelas, serían componentes para ensamblaje muy diversos que tengan roscados, avellanados, dos piezas ‘L’, piezas con forma, etc.

Las piezas posibles para elevación o automoción son también muy diversas, en series de hasta un millón anual. Los tamaños de componentes, varían entre los cms y los 4 metros. Entre los materiales predominan los aceros y aluminios en espesores diversos.