ToolScope, supervisión del proceso contínuo de máquinas-herramienta

Más que una simple detección de rotura de herramienta

Redacción Interempresas01/03/2013

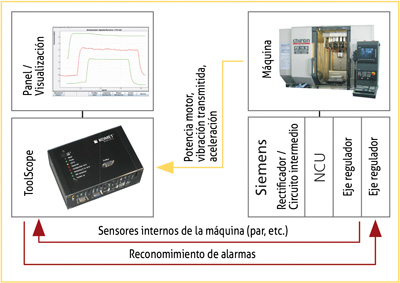

El sistema

Komet ToolScope Brinkhaus está basado en la última tecnología en el campo de los procesos y el control de la máquina. Con un proceso especial patentado para el control estadístico del proceso ahora es posible no solamente la vigilancia de rotura de la herramienta, sino también controlar las variaciones de fabricación significativamente más bajos posibles. Para ello el sistema proporciona, por primera vez, además de los métodos usuales de control del proceso, la posibilidad del control de calidad en el proceso.

Con el sistema ToolScope de Komet Brinkhaus, la calidad de la producción se mantiene bajo control.

El control del proceso y de la máquina está en el contexto de la creciente (y más importante) automatización. Komet Group, uno de los principales fabricantes de herramientas de precisión, tiene la convicción de que esta tarea no debe ser impuesta únicamente para el usuario final. Por lo que decidió ampliar su competencia en este sentido, de acuerdo con sus conceptos de innovación en herramientas y soluciones integrales. En marzo del 2012, Komet Group adquirió Brinkhaus GMBH, con sede en Garbsen, empresa fabricante de sistemas de supervisión y de control para máquinas herramienta. Ahora, la compañía opera bajo el nombre de Komet Brinkhaus GmbH y se beneficia de la presencia global de la compañía matriz. Debido a que el Grupo Komet posee 20 filiales y 50 oficinas internacionales en cinco continentes y 40 centros de ventas y servicio, se asegura un servicio óptimo al cliente.

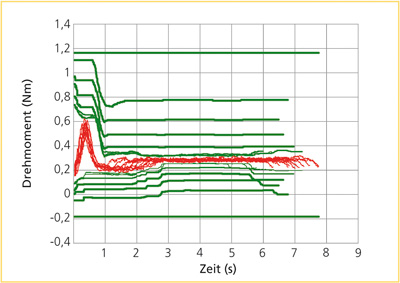

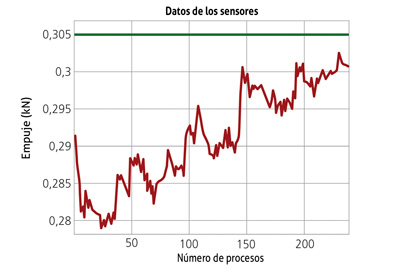

Auto-aprendizaje de los límites de control de proceso 6-sigma.

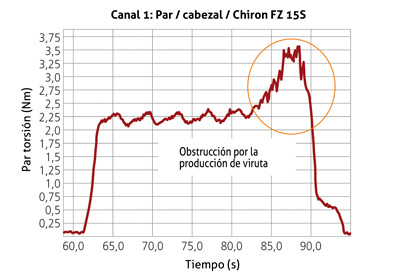

Como fabricante de herramientas que amplia sus servicios en el área del procesamiento, su producto principal es el sistema innovador ToolScope, que se basa en una tecnología revolucionaria en el campo de monitorizado del proceso y control de la máquina. El nuevo sistema de control es extremadamente eficiente, también debido a su facilidad de uso. Así, el monitorizado puede ser iniciado automáticamente por el control al pasar de G0 a G1, sin cambios en el programa de control numérico. Todos los procesos se pueden automatizar y guardar en función del número de herramienta, de la pieza, del nombre del programa, etc. También es posible visualizar cada proceso de forma sencilla y continua. Esta función osciloscopio facilita, entre otros, el proceso de puesta en marcha, por ejemplo, para detectar a tiempo la obstrucción de la viruta al taladrar. Para las copias de seguridad, los datos del proceso se guardan automáticamente.

Obstrucción de la viruta en taladrado profundo, fácilmente reconocible.

El sistema ToolScope proporciona pre-filtrado de las señales de entrada de los filtros predeterminados, como valores medios, valores RMS, varianza, etc. Incluso con señales débiles se consiguen unos resultados excepcionales. La detección de rotura de la herramienta del sistema base contiene un algoritmo de auto-aprendizaje, en el que las bandas de tolerancia se determinan de forma sencilla y automática. Con la función 1plusX (control dinámico) es posible incluso la detección de rotura de herramienta en lotes pequeños (de una sola pieza). Además, el software permite realizar un seguimiento y monitorizado del desgaste de la herramienta. Sobre el establecimiento de límites de alerta, el operario puede ser avisado a tiempo de las herramientas desgastadas.

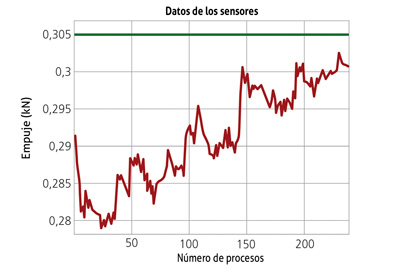

Monitorizado del desgaste.

ToolScope es modular y ofrece numerosas opciones con las que el sistema puede ser utilizado en diferentes áreas. Mediante el algoritmo de ‘control estadístico de procesos en línea’, por ejemplo, se reconocen variaciones del proceso, tales como desgaste, recorridos en vacío largos, cambios en la materia prima, etc. Esto equivale a un control de calidad en el proceso. Con la ayuda del control adaptativo también se puede optimizar el avance, de modo que la potencia efectiva de la herramienta permanece constante. Así, por ejemplo, al desbastar el tiempo de ciclo se reduce significativamente. Además, el avance se puede reducir en caso de rebasar el límite de potencia y proteger la herramienta.

Integración en la máquina-herramienta.