Metrology and Quality in the factory of trucks of the future

Nowadays speak of control of quality like control of the corresponding pieces to a determinate project, each provider sends a report of discreet points of each one of his pieces for validation of these, afterwards in the plants of assembling manufacture and tune the lines of production also with a series of discreet points, the points of reference.

But of this form only control a series of discreet points of the piece. What occur if there are appearances of the piece that do not control and can suppose problems in the setting? They arise problems and delays that involve losses of time in the tuned, increase of costs and decrease of the productivity.

This solves with a technology of catchment of clouds of massive points, with which achieve a control no only of some discreet points but of all the volume, of the geometry and of the cut of the piece, ensuring that each one of the pieces of a project is correct in his whole. From this concept the relation of the big factories of automotive sector with his providers changes, since the information generated by this catchment of massive clouds deposits in a server of the manufacturer of automotive sector and this can realise different analysis with all this information no already on each one of the individual pieces, but the manufacturer can realise the analysis of virtual assemblings of all the pieces of a determinate project analysing interferences and other diverse appearances in said analysis.

This form to work ire carrying little by little what today understand like quality to another much wider concept that it is the ‘analysis'.

So that this form to work can impose and give place to a new order of operation to global level the technology that give place to this massive catchment of points and to the step of concept of quality as we understand it today to the concept of analysis, has to have a series of characteristics so that it can be considered a global solution. By a part this technology has to be able to use in way CNC of a reliable form. Said solution CNC will be considered like the technological base for the globalisation of the quality to all the company. On the other hand, and so important like the first, said technology has to have the capacity to be able to be applied in the ‘line of production', that is to say, in hostile environingingmental surroundings (vibrations especially). And finally this technology has to can attract of big fast form quantity of information in the times of production.

Once attained this advance, the quality leaves to be understood as we understand it today and will happen to have like aim the control of the lines of production so that like consequence of this control of the lines of production the manufacture was optimum. The control happens to focalizarse in the process since what interests us is to produce well.

Can control the process in the own line supposes a revolution to level of internal approaches of the own marry matrices and involves a restructuring of the departamental structures of the same. The quality and the production engloban in an only department since the end is to control the lines to produce of a suitable form, the reports of quality as we understand them to day of today, every time will be more residual, since it happens to the concept of “analysis“, for what precise of a network centralised of servers where each one of the departments can access to analyse the possible competitions of said departments, for example subject of estanqueidades, virtual assemblings, etc.

The factory of the future will have like base of his different control solutions based in the same technology. Like main base will have solutions of catchment of points in the different processes to control, with which will control said process in the own line and will be able to take the corrector actions of said process in base to said information.

These new technologies of measurement, nevertheless, go to be followed conviviendo with other systems of measurement by coordinates in series for those processes that can need more time of catchment of results that the time that would have this process in the line of production. Equally convivirán with systems of manual analyses to control different problems that can arise in different points of the line of production no controlled. The paper of the MMC as we understand them nowadays, will specialise in playing a paper of pattern and control of the different systems of which have spoken previously.

The factory of the future already is a reality in the present

The approach exposed previously could seem a futuristic approach and no current, however the big marks of the sector of the car are nowadays in the research of this “modus operandi”, pursuing the reduction of costs and the increase of the productivity, an aim imposed by the current reality of the sector of the car of decrease of margins and need of increase of the productivity, the big marks of the sector of the car work in this sense.

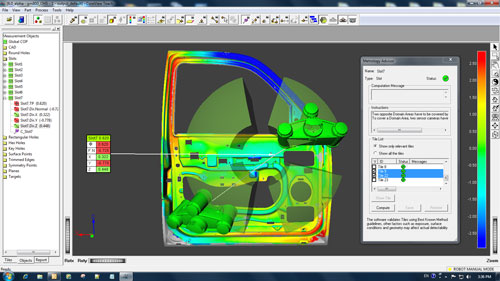

One of the companies of the sector of the car that more advanced finds in this way is the Spaniard Seat. The signature finds in this process of globalisation of the quality in all the company and has internalised to level of company the advance to ‘measure' to ‘analyse'. The pertaining Spanish company to the Group VW has installed already, in the line of production of the mobile elements of the bodywork, of the model Audi Q3 and also of the new Seat León, a solution of catchment of information of clouds of points that achieves to obtain information on the same line of production with the sufficient quality to be able to use by all the departments of the company: Quality, CPD, Processes, Production, etc. This supposes a remarkable increase of productivity and a reduction of costs.

The step of measurement in the department of quality to ‘globalizar the quality' in all the company through the analysis and control of the process, with an only information taken in the own line of production, is a developing reality already at present, of which Seat is pioneering in the sector of the car.

current Technologies like base of present and future solutions in automotive sector

- Photogrammetry – Luz Blanca

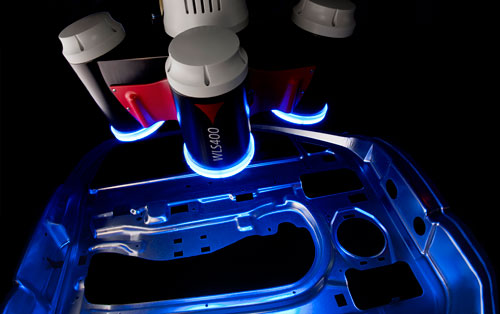

The system of measurement with white light Cognitens WLS400To of Hexagon Metrology is a flexible solution for metrology of workshop in real time. Said system purchases abundant dimensional information from the objects measured independently of his size, his complexity or his geometrical characteristics. This solution surpasses the demanding environingingmental conditions of the workshop, like the vibrations or the changes of temperature and of lighting, and is applicable with all the common industrial robots. So much the Cognitens WLS400M manual like the Cognitens WLS400To automatic use the technology of vision estereoscópica digital to generate data 3D.

Cognitens Is the provider specialist in solutions of optical measurement 3D for industrial applications, and has a big implantation in the sector of automotive sector. This new system provides tools and processes for the capture, the analysis and the distribution of information of dimensional metrology highly significant, with the end to give support to different activities of the industrial engineering, like the tooling, the production of pieces, the assembling, the quality and the control of process. Between the customers of Cognitens explain manufacturers leaders of the sector of automotive sector eat: Seat, General Motors Corporation, Chrysler Group, Ford Engine Company, Toyota Engine Company, Volvo, Deep Engine Company, Mazda Motors, Nissan, Daihatsu, Suzuki and others.

- Laser Tracker

A standard of long length in the industrial metrology: the systems Laser Tracker of Leica are pioneering in terms of precision, reliability and durability in the sector of the machines of measurement of portable coordinates. The modern Laser Trackers of the wallet of products of Hexagon Metrology reach precisions very elevated in volumes of 320 m in an alone station, ideal for adjust and installation of any line of manufacture.

The extension or automation of the system with scanners guided manually, palpadores wireless or robotic applications open an enormous spectrum of possible applications. The result: they realise swift measurements and highly precise supplying them directly to the production allowing saving in costs and improvements in the quality.

These equipment no only use to check pieces but also frequently use in automotive sector to adjust and check the machinery or toolings of manufacture. The Leica Laser Tracker is the ideal team to adjust and check toolings of any size with an ease and enormous rapidity thanks to his integrated cheese cheese technologies like the PowerLock and the portability of the team that with his batteries of lithium and communication wifi allow to use the team in any location of the plant.

- Arms of portable measurement

The Romer Absolute Arm with scanner laser incorporated is a MMC (Machine of measurement of coordinates) portable that allows the measurement 3D with or without contact. The scanner laser is integrated cheese cheese in the arm, which allows to certify the system of complete form according to international rules B89 and VDI/VDE.

The arms of portable measurement allow to take measures directly in the surroundings of manufacture, where the improvements of process result more beneficial. Without prolonged time of installation, with a simple operation and measurements 3D always reliable. The arms articulated can instrument with palpadores of distinct lengths and cabezales of scan to measure even the hardly accessible points already was of optical way or by contact. These machines of measurement of portable coordinates are attaining an every time greater introduction in all th

With the sensor laser CMS 108, the Romer Absolute Arm offers performance of first class even in complex surfaces and in pieces of work manufactured with the types of material more difficult. It does not require it adjust manual of the power of the laser since the control is automatic point ready, adapting to real time to the colour and shines of the surface. CMS 108 is the first scanner laser with function zoom, what allows three widths of scanned different, ideal to measure big pieces to greater speed or small with maximum detail.

- MMC

The MMC follow having a direct application in the sector of the automotive sector, already was for the measurement of bodyworks of big volume, for the verification of all the systems of measurement or also in the processes of inspection of elements that require a very high precision, like gears, gear boxes, etc.

The random inspections of the bodyworks in the rough of the lines of weldings of a lot of factories of trucks realise in bypass of form totally automatic in systems Dea Bravo HP. The open design of the machines of measurement of horizontal arm simplifies the load of the bulky bodyworks in the rough.

The aseguramiento of the quality of complex pieces like the motors realises with MMC of very high precision Leitz.

For all these systems can choose between tactile and optical sensors, and the software PC-DMIS realises the treatment of the data of measurement, to have the most complete analysis and all the necessary information.