Desarrollo de interfaz flexible a medida para robot

(Instituto Tecnológico de Veracruz, Mexico)01/09/2003

Introducción

Como requisito previo se ha desarrollado la aplicación DNC [1] que controla el Torno CNC y nos encontramos con la necesidad de la realización del control del robot para permitir la integración [2], [6] y poder realizar el control de información de forma distribuída, teniendo en cuenta la aplicación de nuevas tecnologías basadas en Internet. En este trabajo el objetivo principal buscado es la realización de una interface que permita la cómoda manipulación y programación del robot.

Metodología Experimental

El desarrollo de los robots está estrechamente relacionado con el de las otras tecnologías de fabricación comprendidas dentro del concepto genérico de CAM. [5] [7].

El robot System Robot RM10 [4] es en el que centraremos nuestro estudio y desarrollo, ha sido adquirido para el laboratorio del área de Ingeniería de los Procesos de Fabricación de la Universidad de Vigo. Es de tipo antropomórfico y cuenta con 6 grados de libertad, accionamientos por medio de servomotores de A.C. y la capacidad de carga es de 10 kg.

En la fase experimental se realiza un estudio previo para la determinación y valoración del lenguaje o lenguajes de programación a utilizar, para el desarrollo del entorno de trabajo, así como para resolver el problema de la comunicación con el sistema, ya que no se disponía de información de ningún protocolo de comunicación utilizado por parte del fabricante. En un principio se ha desarrollado una interface que simula el panel de control del robot para lo cual se realizaron las mediciones correspondientes de la señal suministrada por el control via puerto serie mediante osciloscopio. Una vez traducido el mapa de señales que se obtiene mediante el panel de control se ha procedido a la realización de la interfaz en el programa de desarrollo Visual Basic 6. Por otra parte se ha necesitado realizar un circuito paralelo para decidir si la entrada se realiza bien por el panel de control del Robot o bien desde un ordenador. Para el desarrollo del módulo de comunicaciones, via RS232, [3] ha sido necesario en primer lugar medir las velocidades y parámetros de comunicación.

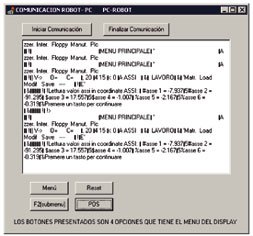

La figura 1 refleja todas las opciones que se tienen en el Panel de control del robot, las cuales se han utilizado para el desarrollo de la nueva interfaz. En una segunda interfaz se decidió implementar una serie de mejoras como son por ejemplo el manejo de estas mismas instrucciones desde el ordenador utilizando ahora el teclado para enviar señales haciendo la manipulación más fácil para el usuario, utilización de teclas en formato contínuo, lectura de los mensajes de respuesta, módulo de programación, edición, carga y descarga de programas. La aplicación para el robot, exige seguridad en aspectos industriales y calidad en aspectos de producción por lo que la aplicación nos debe permitir la administración de nuestras herramientas en tiempo real y la posibilidad de la programación y ejecución de programas por lo que se desarrollaran los siguientes módulos en el programa de desarrollo Delphi: comunicación bidireccional ROBOT – PC, PC – ROBOT, configuración de la comunicación, estudio de señal de recepción, movimientos de ejes del robot, programación del robot, y administración en tiempo real del robot.

Para el reconocimiento del protocolo de comunicación y de los valores más significativos del robot se tuvo que realizar una serie de funciones para la limpieza de la información debido a que las cadenas de datos contenían demasiados caracteres basura e hizo difícil la lectura de dicha información.

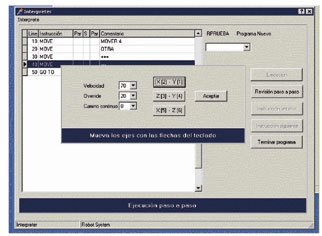

Para la programación del robot se realizaron los módulos siguientes: Creación de nuevos programas, carga de programas desde el robot y desde el PC, almacenamiento de programas en el robot y en el PC, simulación de ejecución paso a paso, así como, la programación del robot (figura 4).

Un módulo de vital importancia es el del manejo del robot en tiempo real y esto quiere decir que nuestra aplicación es capaz de mover y ejecutar instrucciones configurando al robot para un posible inicio de proceso, movimiento o programación. (figura 5). El módulo realiza una serie de envíos de instrucciones interpretando y configurando lo que el usuario ha querido hacer.

Por último, se está realizando un módulo muy interesante, en fase de desarrollo, consistente en la idea de poner en marcha la aplicación en un Intranet desarrollada en Java con los movimientos básicos del robot pensando en una aplicación distribuida.

Resultados y discusión

Como objetivos a posteriori se plantean la depuración de la comunicación distribuída y la integración con otras aplicaciones desarrolladas que permitirían el acceso según distintas distribuciones geográficas. En nuestro caso se reduciría a una simulación de acceso desde el aula CAD/CAM del área de Ingeniería de los Procesos de Fabricación, con comunicación a un servidor de aplicaciones, que ejecutaría la aplicación de control.

Conclusiones

Además, la aplicación implementada permite el desarrollo de la programación del propio robot de forma amigable pudiéndose realizar de forma práctica sin necesidad de conocer el lenguaje de programación específico del Robot RM10.

Por otra parte, la aplicación permite la capacidad de introducir ciertas mejoras adicionales gracias a la modularidad del propio software con objeto de poder ser ampliado a otro tipo de dispositivos o crear el módulo de integración de la célula conformada por distintos elementos, además de la ampliación de librerías a otros tipos de robots y permitir la expansión cómoda de la aplicación.

Con respecto a las tecnologias que forman la estructura de la red distribuida podemos mencionar que estas mismas están convirtiendo las transacciones en un mundo de servicios web. Esta aplicación permitirá en un futuro la utilización de la misma para el desarrollo de utilidades de control remoto, y control distribuído con objeto de realizar un sistema integrado de Fabricación basado en web.

5. Referencias

[2] Chang Hsin-Chi, Lu Wen F, 1999, WWW-Based Collaborative System for Integrated Design and Manufacturing, Concurrent Engineering: Research and Applications

[3] EIA232E – Interface Between Data Terminal Equipment and Data Circuit-Terminating Equipment Employing Serial Binary Data Interchange, Electronic Industries Association.

[4] Industrias LANBI, Instrucciones de primera puesta en marcha, 1995.

[5] Manual Mitsubishi Industrial Micro robot System. Model RV-M1. BFP-A5191EB.

[6] Rodgers Paul A, Husor Avon P, Caldwell Nicholas H.M, 1999, Design Support Using Distributed Web-Based AI Tool, Research in Engineering Design.

[7] Ulrich Feth, Robot Simulation and Off-Line Programming Software, 1997.