Construcción de coches: comprobar y producir con más flexibilidad

16 de abril de 2012

Los constructores de coches y sus proveedores forman parte de uno de los cinco grupos principales de visitantes a los que va dirigida la feria Vision 2012 junto con la construcción de maquinaria, la industria electrónica y de electrotecnia, el sector del procesamiento de imágenes en sí, y la tecnología médica. Según una encuesta realizada entre los visitantes a la Vision 2011, aproximadamente el 17% procedía del entorno de la industria automovilística. Además, el departamento especializado en el Procesamiento Industrial de Imágenes dentro de la Asociación alemana de constructores de maquinaria (VDMA), junto con los fabricantes de automóviles y sus proveedores ocupan el primer puesto entre los clientes de tecnologías de procesamiento de imágenes. Ellos son responsables de una cuarta parte del volumen de ventas global dentro del sector alemán de procesamiento de imágenes en el 2010.

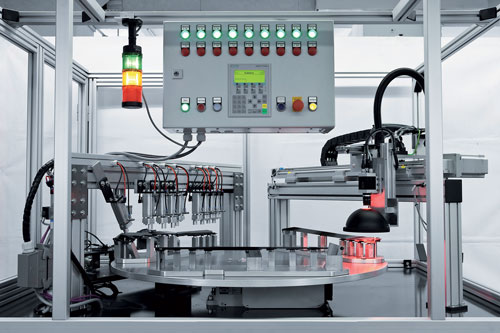

Las altas exigencias de calidad en la producción de vehículos implican nuevos retos para los fabricantes del ámbito de procesamiento de imágenes, tal y como lo demuestran algunos de los expositores de la Vision 2012: “Un reto para los modernos sistemas de procesamiento de imágenes es, por ejemplo, distribuir las complejas tareas de comprobación en varias tareas inteligentes, de modo que el usuario las pueda seguir controlando y dominado”, afirma Hansjörg Hutt, asesor de proyectos MV de Festo. Para los proveedores de la industria automovilística se trata de comprobar que los manguitos de goma están bien montados en los revestimientos interiores de los turismos. Hasta la fecha, el problema ha sido la relación entre el tamaño del componente del revestimiento y el manguito de goma relativamente pequeño y la resolución necesaria para el sensor. Con el fin de poder detectar con seguridad los fallos de montaje, Festo se basó en la adaptación del campo visual de la cámara a un solo manguito en vez de a toda la pieza de revestimiento y en el desplazamiento de la cámara de una posición de comprobación a la siguiente. El truco: el sistema de cámara se autoposiciona gracias al PLC integrado, y la iluminación del domo es guiada también de forma sincronizada, sin ningún tipo de comunicación con el PLC de orden superior. Según Hutt “la ventaja de este sistema es que gracias a la pequeña sección de la imagen se consigue una alta resolución y, por lo tanto, una elevada precisión, siendo las relaciones de iluminación estables y homogéneas a la vez que se reduce la necesidad de comunicación con el control de orden superior. Esto permite suprimir un PLC para la manipulación, lo que a su vez reduce los costes”.

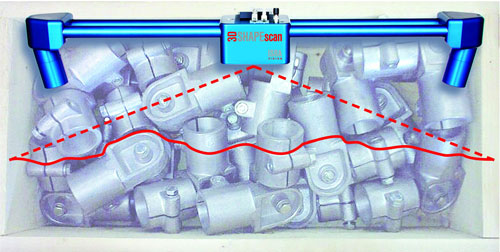

Cada vez son más frecuentes las situaciones en las que no es suficiente tomar una imagen en 2D. Esto es lo que han podido detectar, por ejemplo, los expertos de ISRA Vision, que también son expositores de la Vision 2012, al retirar directamente con el robot piezas sin clasificar de un depósito de transporte y suministrarlas inmediatamente y sin ninguna laboriosa construcción mecánica al proceso de producción. A modo de ejemplo se menciona la construcción bruta de coches, donde un robot debe retirar de un contenedor el material bruto para la forja de discos de freno. “En la práctica no basta con que el robot realice siempre el mismo movimiento", afirma Nicole Rüffer, gerente de marketing de ISRA Vision, “sino que además debe ser capaz de poder reaccionar de forma flexible frente a otras posiciones del objeto. Las soluciones con sistemas de cámaras en 2D fracasan a menudo porque las relaciones de contraste son tan difíciles que no permiten la visión en profundidad”. A tal fin, este fabricante ofrece una solución altamente flexible con el sensor 3D SHAPEscan cuya inteligencia especial radica en el sofisticado software. En combinación con dos cámaras estándar y una iluminación especial por láser, este sensor permite determinar la posición exacta de cada una de las piezas en la caja. “De este modo las empresas de producción pueden ahorrar considerablemente en costes y en valioso tiempo de producción, y aumentar al mismo tiempo la flexibilidad de la producción de forma significativa. Todo ello acompañado por una menor emisión de ruido, una instalación sencilla y prácticamente sin necesidad de espacio adicional”, así describe Rüffer las ventajas.

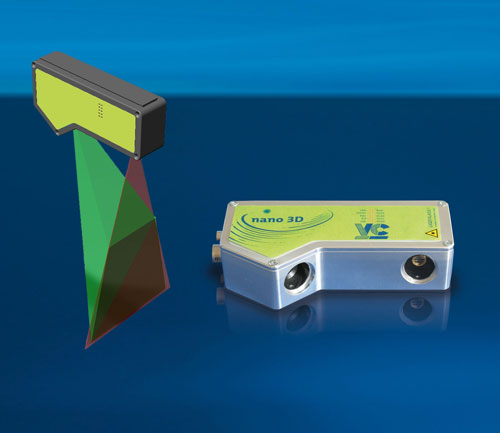

Pero la industria automovilística se beneficia también de las innovadoras cámaras inteligentes. En este sentido, Vision Components, expositor de la Vision 2012, recomienda las cámaras en 3D VC-nano para efectuar el control de calidad y la guía robotizada. Estas mismas cámaras han sido utilizadas con éxito por EngRoTec-Solutions, por ejemplo, en estaciones en línea durante el proceso de producción para la medición de laterales de vehículos. Vision Estas cámaras inteligentes son simplemente perfectas porque su estructura —láser, cámara e inteligencia combinados en una misma carcasa— permite que puedan ser utilizadas para tareas de comprobación tanto en 2D como en 3D, lo que ha permitido aumentar enormemente la eficiencia de las instalaciones”, afirma Miriam Schreiber, gerente de marketing de Vision Components. El procesador integrado que permite procesar inmediatamente los datos de las imágenes tomadas supone una ventaja prestacional para la cámara inteligente. De este modo es posible evacuar las piezas no conformes lo antes posible. Además, según la Señora Schreiber, se reduce al mínimo el número de componentes y, por lo tanto, también su mantenimiento.

“Hasta ahora, los sistemas de procesamiento de imágenes han sido instalados y controlados principalmente por especialistas. En el futuro, cada vez más usuarios sin conocimientos específicos utilizarán soluciones de procesamiento de imágenes, ya que estas tecnologías resultan ser fundamentales para muchos otros sectores más allá de la industria automovilística”, comenta Rüffer. Los retos del futuro son un manejo intuitivo, unas interfaces de control atractivas y unos automatismos que funcionan perfectamente. Rüffer continua: “Resulta imprescindible evitar las parametrizaciones complejas, por tanto, la capacidad de autoaprendizaje de los sistemas debe ser cada vez mejor”.

Este año la Vision será especialmente interesante ya que celebra su XXV aniversario y es la primera vez que todos los expositores están bajo un mismo techo en el pabellón elevado 1 del recinto ferial de Stuttgart. Más de 21.000 metros cuadrados brutos preparados para la presentación de innovadores componentes de procesamiento de imágenes como cámaras, sensores, digitalizadores de vídeo, iluminaciones, láser, ópticas, objetivos, software, sistemas de procesamiento de imágenes, soluciones de aplicación y servicios. En este cuarto de siglo, la Vision se ha transformado como plataforma de presentación y comunicación en una feria que reúne a todos los actores clave. Además, cada vez está más enfocada a las aplicaciones. Un variado programa marco brindará también este año la posibilidad de satisfacer la curiosidad por las últimas tendencias, tecnologías y ejemplos prácticos del procesamiento de imágenes.