Diseño y prototipado de un robot autónomo para la limpieza automática de huertas solares

30 de marzo de 2011

Se han realizado diferentes estudios destinados a analizar y cuantificar el impacto de la suciedad sobre el rendimiento de las placas solares y todos ellos concluyen que el polvo y la suciedad que se deposita sobre su superficie producen pérdidas de irradiación en las placas solares disminuyendo la potencia de salida de los módulos que las conforman. Según el Informe Anual 2008 de la Asociación de Industrias Fotovoltaicas (Asif), las pérdidas pueden estar en torno al 3%, pudiendo alcanzar hasta el 15%, cuando un valor óptimo para dichas pérdidas estaría sobre el 0,5%. Las pérdidas estimadas, por MW instalado, a consecuencia de la suciedad acumulada en la superficie de los paneles pueden oscilar entre 18.404 y 30.673 euros anuales.

La empresa Solar Bright S.L., en colaboración con el Instituto de Desarrollo Industrial del Parque Científico y Tecnológico de Albacete y la Universidad de Castilla-La Mancha, ha ejecutado un proyecto de I+D, cofinanciado por la Junta de Comunidades de Castilla La Mancha a través del los fondos Feder y el CDTI (Ministerio de Industria), para el desarrollo de un método de limpieza automatizado, seguro, rentable, sostenible y efectivo.

Las especificaciones técnicas acordadas entre la empresa solicitante, Solar Bright S.L., el Instituto de desarrollo Industrial y la Universidad de Castilla-La Mancha para alcanzar el objetivo principal del proyecto fueron:

Capacidad de limpiar placas solares fijas de una o dos hileras

El efector de limpieza debe tener al menos la longitud de dos hileras de paneles (>3,80 metros).

Debe limpiar eficazmente las placas

Tras el proceso de limpieza, las placas deben recuperar, al menos, el 97% de su producción umbral.

Debe operar de forma segura

El proceso de limpieza debe tener una tasa nula de deterioro de los paneles, por lo que la limpieza se llevará a cabo teniendo en cuenta la presión y temperatura máxima admisible por los paneles.

Debe ser autónomo

Debe tener capacidad de limpiar de manera autónoma al menos 8 horas.

Capacidad de limpiar de forma rápida

Debe ser capaz de limpiar al menos a una velocidad media de 1 km/h.

Debe ser ligero

El peso del conjunto no debe ser superior a 3.500 kilos.

Debe ser fácil de manipular

Un solo operario debe ser capaz de operar el prototipo.

Problema tecnológico

Después de meses de experimentación y estudio, se determinó un procedimiento de limpieza basado en la utilización de vapor de agua como único producto de suministro. El procedimiento de limpieza permitía limpiar en movimiento a una velocidad lineal de más 1 km/h, es decir, un panel cada 1, segundos, con un consumo de agua bajísimo, 166 centímetros cúbicos por panel, y recuperando el 100% de la eficiencia de los paneles.

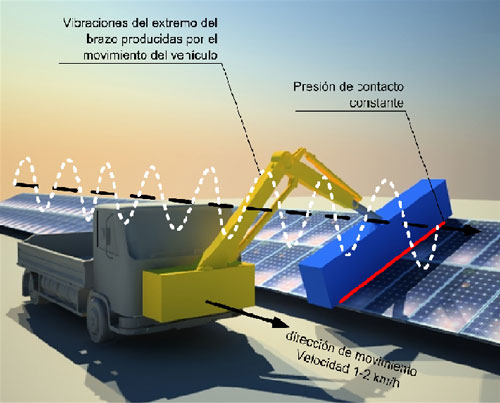

Sin embargo, este procedimiento exigía un contacto entre la herramienta de limpieza y el panel muy constante y controlado en presión. La herramienta de limpieza fue montada en un vehículo comercial sobre una pluma hidráulica que durante el movimiento del vehículo sufría oscilaciones de aproximadamente 3Hz. de frecuencia y 600 milímetros de amplitud. De esta forma, la herramienta de limpieza debía mantener una presión constante sobre el panel con independencia de las vibraciones sufridas por el extremo de la pluma hidráulica durante el movimiento del vehículo sobre las calles de una huerta solar. La figura 1 muestra un esquema del escenario descrito.

Mecanismo

El sistema mecánico utiliza un mecanismo de cuatro barras que traza una línea recta para el movimiento de uno de los extremos. El otro extremo se mueve mediante una barra motorizada unida al chasis mediante una biela. La motorización de las barras no se hace uniéndolas directamente a la reductora del motor si no que se utiliza un mecanismo de cuatro barras. De esta manera se aísla al motor de reacciones peligrosas, además se sintetiza este mecanismo para que tenga una respuesta lo más lineal posible. El sistema también cuenta con dos muelles que se diseñaron para ayudar a los motores a mover la herramienta de limpieza.

Contacto controlado por presión

La presión ejercida sobre los paneles será proporcional a la intensidad que atraviesa el devanado de los motores. Manteniendo consignas de intensidad constantes se puede garantizar presión uniforme sobre los paneles. El control tiene en cuenta que nunca se debe perder el contacto entre la herramienta de limpieza y el panel. De igual forma, se podrá conmutar a un ‘modo manual’, donde el operario es capaz de operar la posición del mecanismo con un mando situado en la cabina del vehículo (modo transporte).

La aplicación de control desarrollada en la plataforma Crio lee la posición de los motores y consigna los mismos para mantener el contacto permanente entre la herramienta de limpieza y los paneles. De igual forma, asegurado el contacto, mantiene el nivel de presión sobre los mismos según una consigna seleccionada desde el operario en la cabina del vehículo.

Conclusión

La figura 2 muestra el aspecto final del prototipo, denominado comercialmente Rolhus (Robot Limpiador de Huertas Solares) y el resultado de la limpieza.

Las características generales del prototipo desarrollado son:

- Recuperación de potencia: 97-100%

- Consumo de agua: 150-200 cc/panel

- Autonomía: 6-14 horas

- Velocidad de limpieza: 1,2s-1,6 s/panel

- Número de operarios: 1