Control y monitorización de plantas de desoxigenación

7 de mayo de 2009

Ambos sistemas, especialmente las plantas de absorción, se pueden diseñar para producir con un contenido de oxígeno mucho más bajo, aunque no resulta económico. Alternativamente se pueden utilizar las plantas de desoxigenación (‘de-oxo’) para retirar los restos de oxígeno de los productos de estas plantas.

Las plantas de desoxigenación funcionan añadiendo hidrógeno al nitrógeno de bajo grado, haciendo reaccionar la mezcla resultante al pasar a través de la columna de material catalíticamente activo. El hidrógeno reacciona con el oxígeno residual para formar agua. La siguiente reacción química describe la reacción:

2H2 + O2 + N2 = 2H2O + N2

Si es necesario, el gas puede hacerse pasar por un secador. Por muchas razones técnicas y de seguridad, muchos procesos que utilizan el gas producido por este sistema no toleran ningún exceso de hidrógeno en el producto. El problema, por tanto, es añadir el hidrógeno justo para reaccionar con el oxígeno.

Los acercamientos más comunes y la solución planteada por Hitech

Uno de los acercamientos más comunes al problema ha sido monitorizar la concentración de oxígeno en el producto del generador de nitrógeno y su flujo al reactor de desoxigenación. Un microprocesador analizar estos valores y extrae el ratio de flujo del hidrógeno requerido para reaccionar con el oxígeno. El flujo requerido se ajusta entonces mediante un caudalímetro másico situada en la línea de alimentación de hidrógeno. Como comprobación de seguridad, los productos se monitorizan mediante un analizador de hidrógeno cuya resolución es como mucho +/-50 ppm.

El método funciona pero tiene 2 grandes inconvenientes: 1) es caro, ya que requiere analizadores de precisión, rotámetro, ordenadores y caudalímetros másicos; y 2) el resultado es que el producto contiene cantidades de hidrógeno relativamente importantes.

Un acercamiento alternativo es utilizar un analizador de oxígeno de Hitech Instruments con sensor de zirconio. Los analizadores de oxígeno con célula de zirconio tienen una cantidad de atributos únicos, dos de los cuales lo convierten en ideal para esta aplicación. Primeramente, pueden medir el oxígeno en concentraciones desde 1 hasta 10-23 atmósferas, y en segundo lugar, pueden hacer esto con un tiempo de respuesta de fracciones de segundos. Miden la concentración de oxígeno de la misma forma que los electrodos de pH miden la acidez.

Y de la misma forma que el electrodo de pH se utiliza para monitorizar la neutralización de un ácido por un álcali, puede utilizarse un sensor de zirconio para monitorizar la “neutralización” del oxígeno con hidrógeno. El punto de “neutralización” se produce cuando los reactivos están exactamente en la proporción correcta para no producir ningún exceso. Este punto se denomina normalmente punto estequiométrico. En él, las concentraciones de oxígeno e hidrógeno son debidas totalmente a la disociación del agua producida por la reacción y son del orden de partes por billón.

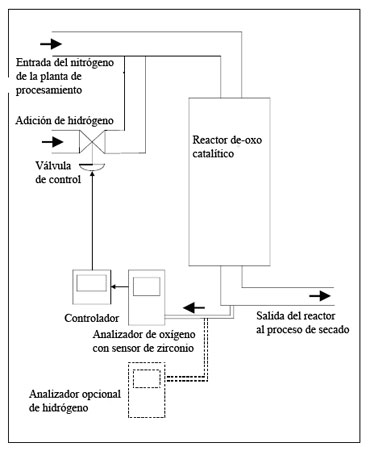

La figura 1 muestra el sistema general para monitorizar y controlar una planta de de-oxo utilizando un analizador de zirconio de Hitech Instruments. Utilizando este acercamiento se obtiene un controlador de coste inferior con un sistema mucho más simple. Si se requiere, se puede incorporar un analizador de hidrógeno adicional para monitorizar una situación de fallo, por ejemplo, en el caso que fallara el reactor de-oxo.