Renishaw enters the market of 'retrofit' of MMC installed with a solution 'integrated whole'

February 6, 2009

All brands of MMC users now have the opportunity to transform the performance of their measurements by updating to the innovative systems of metrology of Renishaw. The company now offers a comprehensive range for MMC installed, based on the universal MMC control UCC2 and the new software of Metrology for MMC Modus. With the combination of the unique range of sensors of shot by contact, exploration and 5-axis and the recent investments in staff and facilities of Ukas, Renishaw has assembled all the elements to develop a powerful Division of 'retrofit' business of MMC installed.

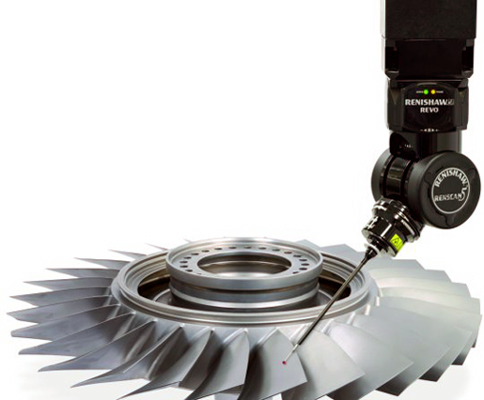

Although the exclusive system of measurement of 5-axis Renishaw Revo has been available through Mitutoyo, Wenzel, Dukin and Metris for a time, until now, users of other machines not could take advantage of this revolutionary technology. The operational benefits of increased productivity, lower measurement and preparation times and greater automation of the tasks of measurement are now available to users on any machine MMC.

"The introduction of the new Modus software and investment in staff and facilities around the world reflects our great commitment to the sector of installed MMC," says Ben Taylor, director Executive Deputy of Renishaw. Moreover, "we can now offer customers of all brands of MMC - including Hexagon and Zeiss - a solution complete with cutting-edge technology in all aspects, with the guarantee of security and the direct service of Renishaw." "Moreover, our clients of installed machines will benefit from immediate access to our future innovations in measurement technology."

A professional approach minimizes the risk

"Renishaw thought that the customers of MMC installed are entitled to receive the same level of professionalism and quality by a 'retrofit' MMC to acquire a new machine", says Brian Gow, marketing director of the Division of MMC of Renishaw products. He continued "we have put in place a rigorous verification system of the machine which oversees each MMC mechanical and electrical components, and we are committed to maintaining a level of system performance, so the customer knows what they can get before." With an experience of hundreds of UCC drivers installed, we have developed a comprehensive facilities of MMC knowledge base, which is why we provide a 'plug and play' of our control installation. Finally, our UKAS certification gives customers confidence in the accuracy of the current machine. "It is managing the details to provide the level of service to which they are accustomed customers of Renishaw."

Assistance and service responsible for Renishaw

Renishaw is aware that the MMC user needed high times of operation of the machine, so a responsible and expert service is crucial. Renishaw provides customers of machines installed a wide range of flexible options of maintenance contracts, which includes software maintenance; calibration, preventive maintenance and emergency technical support visits; assistance outside of working hours and training of high level software. Each contract is specific, allowing the client to select the combination of services which best suits your needs, with the flexibility to study the unused days in the next session.

It also has a range of resources online at renishaw.com, with help topics that can search in Google, frequently asked questions and answers, a forum for debate, software updates, and the convenience of registering help queries.

Investment in staff and facilities

To meet the requirements for installation and technical service of its customers in MMC installed, Renishaw has made investments in staff and facilities. This includes the recent acquisition of Qualis Service GmbH, a company of MMC service technicians for field work distributed by all Germany. It has also hired staff of sales and applications in the USA and Europe.

Renishaw has also established a manufacturing module at its facilities in Woodchester, Gloucestershire, England, dedicated to the Assembly and testing of the kit installed machines. This approach to installed machines minimizes the time spent on the premises, that the system is tested previously and settles 'plug and play' at the time of delivery to the client. These facilities are being implemented in the main subsidiaries of Renishaw in the world.

The elements of success

Renishaw may now offer cutting-edge technology for MMC installed in all aspects, including sensors, controls, and metrology software.

The award-winning 5-axis Revo measurement system provides unprecedented measurement speed, a time of calibration reduced and flexible access to unique functions, through fixed probes or indexing head systems. Equipped with innovative technology, Revo allows users of MMC measure forms of pieces and to increase the performance of production with less operator intervention. With programmable change of sensors and transducers, Revo users can automate even the most complex measurement tasks. It is more, the future sensors Revo, the first of which will allow the measurement of the finish of the surface in a (available at the end of 2009) MMC, integrating for the first time the current tasks of quality control, highly manuals, in the process of inspection CNC.

In addition to Revo, installed machinery customers can choose from the extensive range of sensors of shot by contact and continued exploration, mounted in the standard indexing head of sector PH10. With functions of automation as the change of sensors or probes, has the best performance for various measurement applications. With a common platform for the software and control, customers who choose these sensors may be a transition cost-effective 5-axis measurement system when needed.

The universal control UCC2 for Renishaw MMC is the core of Renishaw to MMC installed. Combined with an amplifier Renishaw servoalimentado, allows a control of precision even in five-axis simultaneous motion in machines of all sizes. It provides also an interface centrally for all sensors Renishaw, able to explore a surface data up 4,000 points per second. It includes a sophisticated system of allocation of machine errors in open format, allows users to make their own calibration, with availability of temperature compensation. The UCC2 very appropriately complies with the standard I ++ DME, which gives users the freedom to use any software of metrology that has a client I ++.

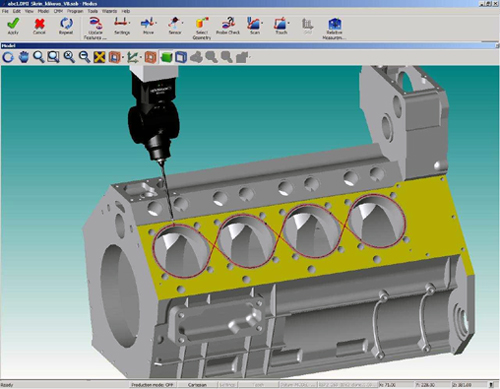

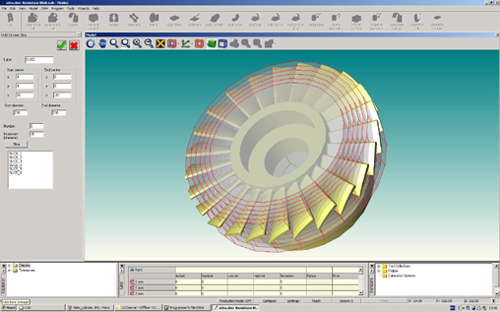

One of these software programs is the new Modus of Renishaw package. Fully compatible with the full range of sensors, including the award-winning Revo, Modus provides a powerful platform for 5-axis measurement. Its main functions include: programming without CAD connection with complete simulation and detection of collisions in 5-axis movements; DMIS native format support; approved mathematical algorithms; generation of complete reports of text and graphics; and flexible results data. Based on recognized Metris Camio metrology software, Modus has been developed by the team of engineers hired recently, and it will be improved to incorporate future technological innovations of Renishaw in sensors and controls.