Entrevista a Ion Garmendia, director comercial de Danobat S. Coop. - División Sierras

En los últimos ocho años ha habido una gran revolución en la tecnología de corte mediante sierra de cinta

¿Qué es el aserrado y para qué tipo de trabajos se utiliza?

¿Qué tipos de sierras existen y en qué se diferencian unas de otras?

También existen las hojas con dientes de diamante, etc., para el corte de materiales como el vidrio, neumáticos, aceros con gran temple etc., generalmente utilizadas en operaciones muy especiales.

Las hojas o sierras de cinta se fabrican en una variedad de dentados, desde un paso de 14/18 dientes por pulgada, para poder cortar espesores de materiales muy finos, hasta dentados de 0,7/1 diente por pulgada, para el corte de diámetros de hasta 2.500 mm.

Las dimensiones de los flejes más utilizados en la industria, son las comprendidas entre 27x0,9 mm y 80x1,6 mm de espesor.

Por último, decir que las hojas de cinta tanto bimetálicas como de carburo, pueden disponerse con tratamientos como por ejemplo baño de nitruro de titanio, ofreciendo la posibilidad de cortar más rápido, con una vida de herramienta superior. Estos tratamientos están resultando una gran revolución en el sector del corte en muchas aplicaciones, donde se requiere una gran producción.

En referencia a la situación actual, ¿Cuáles son los principales debates tecnológicos hoy en día en el campo de las sierras?

Además de lo mencionado, existe una creciente demanda para que el factor del operario tenga la mínima repercusión en la producción obtenida en los diferentes turnos, por lo que en este tipo de máquinas, el operario además de cargar el material, simplemente indica la dimensión de la pieza, su geometría, longitud de piezas a obtener y número de unidades, y es el CNC de la máquina el que se encarga del resto de la gestión de corte, con criterios previamente marcados de fábrica. El objetivo es que trabajos iguales en diferentes turnos, obtengan prácticamente las mismas producciones.

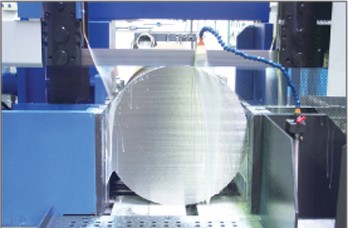

Para poder lograr este grado de autonomía y grado de constancia de las producciones, actualmente se están empleando sistemas de medición, guiado, control, etc., similares a máquinas herramientas más sofisticadas, por lo que, lo que en su día se denominaba simplemente como sierra, hoy en día es una máquina-herramienta de corte.

Como ejemplo, se puede destacar que actualmente el grado de sofisticación requerido nos lleva a emplear husillos rectificados para ejecutar el movimiento y control de corte, en lugar de sistemas más clásicos como cilindros, etc.

¿Cuál es el secreto de una buena sierra? ¿Qué la diferencia de una “no tan buena”?

Realmente pienso que actualmente no existen muchos secretos, pero además de disponer de un equipo completo, cualificado y motivado de personas que desempeñan su labor en diferentes puestos de trabajo, nosotros en Danobat nos sentimos orgullosos de disponer del centro tecnológico ”Ideko”, dentro del Grupo Danobat, donde contamos con unos medios, organización, sistema de trabajo, basado en un estudio del sector, competidores, sistema de análisis de valor, AMFE, taller de prototipos, ingeniería mecánica (cálculos estáticos, dinámicos, térmicos), ingeniería de control, etc., en donde se aprovechan las sinergias producidas en la fabricación de diferentes máquinas-herramientas, con buenas prácticas y sobre todo, involucrando a todo el equipo, trabajando de forma conjunta.

De todo esto, se pretende obtener un producto de calidad, rigidez, y precisión, que esté a la altura de la demanda de los clientes, de fácil manejo, con pocas incidencias, y en cuyo caso sea práctica para las labores de SAT.

En cuanto al mercado actual, ¿Es la importación de sierras una importante competencia para los fabricantes de aquí?

¿Cuántos fabricantes de sierras españoles existen? ¿Y aproximadamente cuántas empresas comercializan sierras extranjeros?

En lo que a tendencias se refiere, ¿hacia donde avanzan las innovaciones de las sierras?

¿Qué características tendrán las sierras dentro de unos años que no tengan ahora?

Pienso que cada vez nos dirigimos a un grado de sofisticación mayor en las máquinas, con el fin de emplear menos máquinas, y con ello menor espacio utilizado, menos personal, mayor y mejor control de los stocks, costes, etc., lo cual desde ya, está requiriendo lo que anteriormente ya hemos citado, más centros de corte.

¿Existe algún factor legislativo, medioambiental o simplemente de “costumbres de los clientes españoles” que condicione de alguna manera la venta de sierras en España?

Para finalizar, ¿cuáles son las últimas novedades de Danobat Sierras?

Para este mismo sector, se han desarrollado líneas de corte y taladro muy flexibles, que pueden ser particularizadas dependiendo de las necesidades de cada cliente. Así, en los ultimos años, hemos desarrollado principalmente tres tipos de taladros automáticos, que les podríamos clasificar en el taladro con cabezal de tipo torreta con cuatro herramientas de mecanizado, el taladro de tres cabezales independientes, con o sin cambiador automático de herramientas, y el taladro de un cabezal con movimiento longitudinal a lo largo de la pieza a trabajar.

Todos ellos, están controlados por CNC mediante software Danmach, compatible con ficheros DSTV.

Además, hemos desarrollado el nuevo centro de corte ASU-ASR provisto de 6 estaciones de carga, y almacén de recogida de restos de materiales comandado mediante un sistema de programación de parámetros de corte automático," Danocut" para los diferentes materiales dispuestos sobre el almacén.

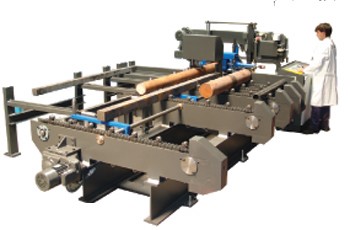

Por último, cabe mencionar la gama de sierras CP-TV "vagoneta" que se encuadra dentro de las soluciones que Danobat ofrece a la prooblemática de corte y manipulación de materiales pesados. La particularidad de este tipo de sierras reside en su mesa móvil o vagoneta, y su modo operativo, lo cual permite un considerable ahorro de los tiempos de manipulación del material. La carga del material se realiza en una posición externa sin que el propio cabezal de un obstáculo para ello. Además, las piezas cortadas pueden permanecer sobre la mesa, sin necesidad de ser retiradas cada vez que se realiza el corte. Una vez que todos los cortes se hayan efectuado, la vagoneta retrocede sobre los railes, de forma que las piezas cortadas puedan ser fácilmente descargadas desde una cómoda posición.