Tecnatom, EADS and Airbus Military aúnan capacities to implement the system TecnaLUS for the first time in Europe

Ultrasonic inspection by means of laser of aeronautical sector component manufacturing sector component manufacturing components in the phase of production

The new system TecnaLUS, in which Tecnatom will have a majority participation, is framed in the project LUS-TEAM, an initiative of technological development in which the three partners aúnan his capacities for the implantation to industrial level of technology of inspection by ultrasounds generated by laser.

This agreement of collaboration with EADS-IW and Airbus Military will allow to Tecnatom put in value his leadership in the development, manufacture, tuned and maintenance of prototypes and equipment of inspection by means of essays no destructive and, in particular, in systems of inspection by means of ultrasounds generated by laser.

Is not the first time that EADS, Airbus and Tecnatom collaborate in a project of similar characteristic. In 2010, the system robotizado Lucie installed in the technological centre Tecnocampus EMC2 of Nantes also for the ultrasonic inspection by laser of aeronautical sector component manufacturing sector component manufacturing components in the phase of development. “The team of the CBC represents a qualitative technological jump, is faster, what will allow to increase the productivity, improve the costs and, therefore, the competitiveness”, explains Antonio Tanarro, manager of markets diversified of Tecnatom. “The integration of industrial robots with the traditional tools hardware and software developed by Tecnatom for the control, acquisition of data and processed of the same, will contribute to improve the process of manufacture of components with new utilities of automation and will add efficiency”, exposes Tanarro.

LUS, the inspection by ultrasounds of the future

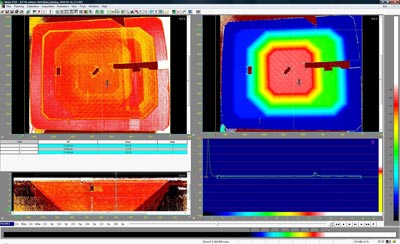

The ultrasounds generated by laser or LUS in his acronyms in English (Laser UltraSonics), constitute a new technology to inspect aeronautical sector component manufacturing sector component manufacturing components of compound material, that offers big advantages with regard to other more conventional technicians like the palpadores traditional and phased arrray. The technology LUS improvement the times of manufacturing and inspection of components during the process of manufacture and operates without need of water or gel like means acoplantes of transmission, since the ultrasounds are generated directly in the surface of the piece. Of equal way, the method LUS allows the control to distance and is much more flexible to adapt to the geometry of the pieces inspected. These advantages do it especially interesting for the inspection of components with complex geometries and pieces of big and small dimensions.