Lantek acude a la BIEMH 2010 con un portafolio de soluciones totalmente renovado

8 de junio de 2010

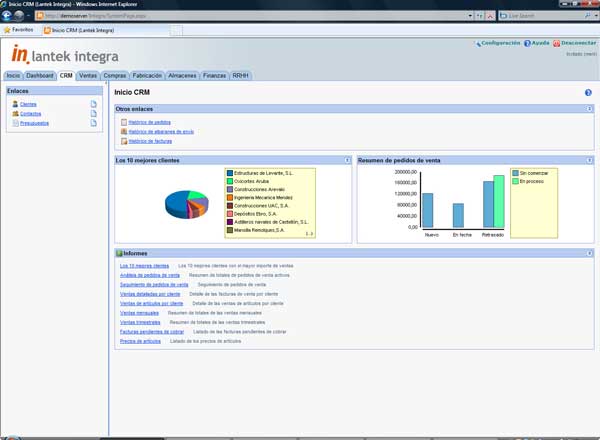

Asimismo, y dentro del marco de BIEMH 2010, Lantek celebró una jornada tecnológica el día 3 de junio, en la que el tema central fue Lantek Integra, la única solución de gestión basada en web para el sector de la transformación metálica que, además, posee completa integración con las soluciones CAD/CAM de la compañía.

Catálogo de soluciones totalmente renovado

Lantek volvió a dejar patente con su asistencia su compromiso y apuesta por las tecnologías innovadoras para el sector de la deformación metálica.

Así, de la mano de su equipo de expertos, la compañía presentó la versión un renovado y completo catálogo de producto en el que una de las principales novedades es Lantek Integra, la nueva y potente plataforma ERP basada en web que incorpora un amplio abanico de funcionalidades y permite la automatización, gestión y control de todos y cada uno de los procesos empresariales en cualquier momento y lugar, facilitando el acceso a la información a través de Internet y mejorando la productividad de la empresa. Asimismo, Lantek Integra está preparada para su total integración con el software CAD/CAM de la compañía incrementando el retorno de inversión y reduciendo costes.

Lantek Integra toma como base una avanzada arquitectura tecnológica y está compuesta por un amplio conjunto módulos, entre los que se encuentran Tesorería, Ventas, Compras, Fabricación, Almacenes, Productos, CRM y WOS. Son muchas las ventajas que aporta este nuevo ERP, siendo una de la que más destaca la optimizar de los procesos de toma de decisiones, gracias a la incorporación de herramientas de BI, reporting y cuadros de mando.

Estas características, a las que se suman la potencia, la alta capacidad de procesado y un manejo fácil e intuitivo, así como el profundo conocimiento y la especialización de Lantek en la industria de la transformación de la chapa y el metal, convierten a Lantek Integra en la solución idónea para las empresas que desarrollan su actividad en este sector.

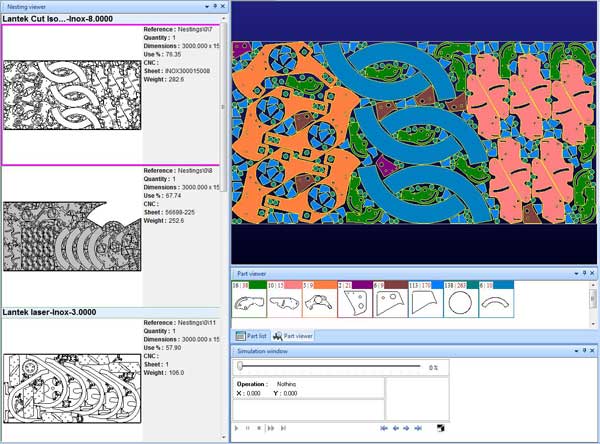

Otro de los productos que Lantek expuso durante el transcurso de BIEMH 2010 es la nueva versión 2010 de Lantek Expert, el software CAD/CAM para corte y punzonado de chapa para máquina-herramienta, en cualquiera de sus tecnologías, ya sea corte por plasma, oxicorte, láser o por chorro de agua.

La solución ha sido optimizada en materia de funcionalidad, permitiendo ahora a los clientes disponer de la más avanzada tecnología en un entorno moderno y funcional. Las novedades incorporadas a la aplicación suponen un importante avance para dar una respuesta eficiente a las necesidades de los usuarios a la hora de abordar los diferentes procesos de fabricación y trabajo en chapa del sector industrial.

Lantek Expert v2010 es una solución extremadamente potente y fácil de manejar, que incorpora una nueva arquitectura que emplea avanzas tecnologías de diseño y programación, en la que se han introducido avances en los métodos de nesting, consiguiendo incrementar de forma significativa el rendimiento de la chapa, así como en la velocidad de proceso. Las nuevas opciones a la hora de calcular los tiempos y costes de las piezas, chapas y productos, permitirán al usuario tener un mayor control de la producción y predecir perfectamente los costes y tiempos de fabricación en su taller.

Por otro lado, otra de las novedades que Lantek presentó guarda relación con la nueva familia de productos para diseño de piezas de chapa en 3 dimensiones, plegado de piezas de chapa y corte de tubos y perfiles, Lantek Flex3d.

Compuesta por un total de 8 módulos específicos para llevar a cabo tareas de plegado y desplegado, trabajar con tubos o perfiles, realizar actividades de diseño integradas con los programas SolidWorks, Solid Edge, Autodesk Inventor, Catia o ProEngineer, así como trabajos de automatización de programación de máquinas de corte con cinco ejes, esta gama ha sido optimizada para ofrecer a las empresas del sector de la construcción de estructuras metálicas un herramienta de diseño ágil y eficiente que se adapte y resuelva las necesidades de cada compañía.

Son varias las mejoras incorporadas en la familia Flex3d, tanto desde el punto de vista técnico como funcional, sin embargo, el módulo Lantek Flex3d SteelWork, es uno de los que mayor cantidad de novedades incorpora. Esta aplicación, específica para el diseño y corte de perfiles estándares (I, U, L, T, H, perfil circular o cuadrado, …) de forma ágil, intuitiva y sencilla, ofrece al usuario una visión real del resultado que obtendrá permitiendo optimizar el trabajo. También cuenta con un sistema paramétrico que permite cambiar los valores de las operaciones realizadas, incluyendo la modificación de los parámetros iniciales de diseño del perfil. Asimismo, puede simular el movimiento de la máquina, el desplazamiento del perfil y las operaciones de mecanizado que realiza cada herramienta, además de estar preparada para generar directamente el programa de control numérico para enviarlo a la máquina (código CNC puro, DSTV, DSTV+ o CAM) y adaptar la información de corte a las características de cada máquina.

Por otro lado, Lantek Flex3d SteelWork es una solución independiente que no requiere de ningún software adicional y que está totalmente integrado tanto con el software CAD/CAM Lantek Expert como con su ERP Lantek Integra, facilitando la gestión total del proceso de venta, de los almacenes/inventario, de lotes y número de serie para la completa gestión de la trazabilidad.