Quality and industrial hygiene

9 December 2011

The no destructive essays (END) more common, recognised and classified by the ASNT (The American Society for Nondestructive Testing) in the practice recommended SNT-TC-1ª, divide in superficial (visual examination, penetrating liquids and magnetic particles) and in volumetric (ultrasounds, currents induced and X-ray). Also they exist other END less common like the acoustic broadcast, the thermography, the essay laser, the proofs of escapes (bubbles, pressure, helium and spectrometry of masses), the vibrations, the electromagnetism of remote field (RFEC), the electromagnetism of low frequency (LFET) and the ultrasonic wave guided (GUL-LRUT).

The profits of the END

The application of the END can have different motivations for the companies, but, definitely, have to base mainly in his multiple profits:

- early Alert

- Increase of the availability and hours of service of components and units

- Decrease of failures and stopped no programmed in units in service

- Guarantee in origin and allocate the quality of the products

- Ensure that the constructions fulfil with the required by the norms and the laws

Main applications

The END can employ to locate defects (faults of penetration, erosion-corrosion, faults of fusion and pores), detection and evaluation of cracks, detection of escapes, determination of position, dimensional measures (for example, thicknesses ultrasounds), preventive and predictive maintenance, essay sustitutorio of other proofs, inspection of new constructions and inspection in service.

Indications and evaluation:

Indication: answer or evidence of a discontinuidad resultant of the application of an END.

Evaluation of indications: process in which it decides the severity of the state of the part or piece, afterwards that the indication has been interpreted. Of the interpretation will arise that the indication is irrelevant or is a discontinuidad, and in this last case will arise that it is a defect or no. Said evaluation carries to decide, then, if the part or piece has to be refused, repaired or accepted for his use. Usually it evaluates by comparison with defects known and following the criteria of norms and applicable codes during the examination (ASME / JOINS-IN ISO).

Visual examination

In the human beings, big part of the information that perceive produces through the sense of the sight. Although in END find nowadays technology very sophisticated with enormous possibilities of detection, possibly there is not any comparable machine in capacity to the human eye. It is thus that has to put in value this method of essay, in occasions, no appreciated sufficiently by his simplicity and that allows to value the state of the object of examination of fast and economic way.

When we have access to the object to examine realise a direct observation. In case that not having access, will have to resort to the remote observation. For the remote observation will help us of mirrors, endoscopios, fibroscopios, motorised robots, videoendoscopios or any another half that allow to have of the necessary information with a sufficient resolution. The fact that it treat of a simple examination, causes that in occasions do not value sufficiently the qualification and experience of the operator.

Penetrating liquids

Treats of a manual method, although it can automate when it applies in series of manufacture. It results costly for massive inspections of components or units in service.

Steps:

- previous Cleaning

- applies the liquid

- Cleaning of the excedente

- Application of the revelador

- final Observation

Employs to detect discontinuidades open to the surface of solid bodies and essentially no porous. We can adjust the level of sensitivity and therefore the capacity of detection, selecting between penetrating coloreados (natural sunlight) or fluorescent (ultraviolet light). It is the most sensitive method for the detection of superficial defects when the conditions of cleaning are optimum (especially in materials no ferro-magnetic) and in occasions uses as I complement of volumetric methods (RT or UT). In difficult geometries (for example, threads) have to consider other methods.

Magnetic particles

This method carries out inducing a magnetic field to a material ferro-magnetic, and then espolvoreando in the surface particles of iron (already was dry or in a suspension). The superficial imperfections modify the field and the particles of iron concentrate in the defects. Only applicable in materials ferro-magnetic.

The defects have to be perpendicular to the lines of field, by what have to generate fields that allow the location in all the directions. It is the most sensitive method for the detection of superficial defects when the conditions of cleaning are not optimum. In occasions, uses as I complement of volumetric methods (RT or UT). Likewise, it has to check that have of sufficient magnetic field to appreciate the possible discontinuidades in the material, for this use the indicators of field.

The method is of fast and simple operation and the indications appear directly on the piece, and are a magnetic drawing of the discontinuidades real. It allows the massive examination of components with a cost contained.

Ultrasounds

Examines all the volume to examine and the energy of the sound reflected represents in function of the time/distance. Up to now the most used technician was the impulse-echo based in the effect of echo that a heterogeneity or reflector produces when being hit by a do of ultrasounds. It stands out by his simplicity of application and interpretation.

In this method the oscillator, receptor, separated or forming an only unit (palpador) with the emisor (only glass), collects the echo of the reflector transforming it in the corresponding indication. The manual essays are of the type of contact and the operator moves the palpador on the piece by slide or successive contacts. In front of an indication of defect or other causes, the operator can detain and explore more thoroughly the suspicious zone, registering all the information (amplitude, form of the echo or position).

Another positive appearance is the fast set up and simplicity of team: device of ultrasounds, palpador, acoplante and piece pattern. As main disadvantages presents: slowness of operation, variations in the join up by different pressure or fault of acoplante, and need of an operator described.

Before initiating an essay is precise to calibrate the team so that it can obtain information of the position and size of the defects detected in the piece subjected to essay. For this is precise to have of blocks of calibración chords with the norms and codes that apply to the inspection. The development of the ultrasounds allows in the actuality have of technicians like “Phased Array” or “TOFD” (Time of Flight Diffraction) that open new possibilities like the digital register of the examination or the replacement of the X-ray.

Currents induced

The essay by currents induced (also are used to to call parasitic currents or currents of Foucault) bases in the principles of the electromagnetic induction and employs generally for examination so much pre-service like service to see the state of materials and components.

A general principle in END is that, the material object of the essay subjects to the action of some physical phenomena that do that the energy flow through the material. The heterogeneities and discontinuidades cause anomalies in the flow of this energy (distortion, reflection, absorption, etc.) that detect from the outside of the sample.

In the case of the CI the energy that puts at stake is electromagnetic and, therefore, does not need any type of contact neither of agent of attachment between the generator and the sample, what turns him into a very fast method and apt for continuous processes.

The CI are common electrical originated in a conductive material by a variable magnetic field and that flow in parallel enclosed lines to the surface of the sample and his sense of circulation is such that produce an opposite magnetic field always to the that generates them.

The magnetic field inductor proceeds, the greater part of the times, of a solenoid by which circulates an alternating current, and that can apply so much in accessible surfaces as no accessible by means of inner probes.

The CI apply in components no ferromagnetic and allow us locate and dimensionar the discontinuidad located. For materials ferro-magnetic have to resort to a variable designated electromagnetism of remote field (RFET) whose capacity is only qualitative. One of the main current applications of the CI is in equipment with do tubular, that allow to identify tubes damaged and predecir the remanent life (preventive/ predictive). The examination of do tubular, allows to detect the different types of damage and decide the suitable moment to execute the actions required (taponar, encamisar or reentubar).

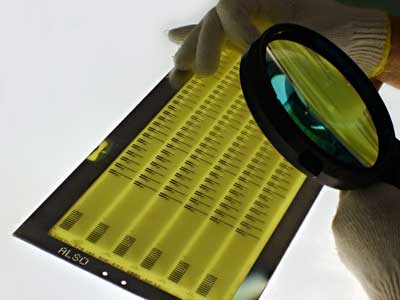

X-ray

Is a method that uses the radiation ionizante of high energy that when happening through a solid material, part of his energy is attenuated because of differences of thicknesses, density or presence of discontinuidades. The variations of mitigation or absorption are detected and registered in a radiographic film, with which obtains an image of the internal structure of a piece or component. The basic principle of the radiographic inspection bases in the property that possess the materials to attenuate or absorb part of the energy of radiation when they are exposed to this.

The X-ray can use in metallic materials and no metallic, ferrous and no ferrous, and provides a permanent register of the internal condition of a material. Besides, it is easy can evaluate the type of discontinuidad that detects .

Limitations of the X-ray:

- Difficult to apply in pieces of complex geometry or zones little accessible.

- The piece or zone has to have access in two opposite sides and does not detect discontinuidades of type laminar.

- Require measured of security for the protection against the radiation of the people.