'High tech' panels for façades in polyester sandwich

But is true that all the crises carry in himself same the opportunity of improvement, and to consequence of this, is evident that the construction will have to transform in a true industry. This presentation treats to signal the peculiarities that affect to the use of the new materials and by extension to the technicians of design and manufacture, mattered of the industrial field, and applied to some activities still so artesanales as they are the related with the construction of buildings.

Here would have to do a clear distinction between houses and singular buildings, but the necessary concisión prevents to go in in fields more own of the sociology and the art tied to the architecture, in profit of the pragmatism. No without manifesting that the singular buildings, seldom thought for house, go very by in front of these last, in the application of new systems and material.

Without forgetting that the ugliness or beauty of our cities depends on the combination of houses and singular buildings, and is responsibility of the architects, happen to the most concrete terrain of the practice. Three fundamental factors differentiate, and move away, the construction of buildings of other industries in which it provides to the customer a product finished and, as in the past it said in the description of units, working.

These are:

· The costs of editorial and development of the project.

· The series and terms of execution.

· The holguras of construction.

In the referred to the project, the technicians of industrial design have imposed in architecture. Sometimes constituting an improvement, and others a problem from the constructive point of view.

Already are generalised the computer programs that allow the perfect geometrical definition of a building, by odd that they are his forms, of the same way that the design of a car, an aeroplane or a batidora of kitchen. But it forgets that the cars, aeroplanes or batidoras, manufacture by cientos, thousands or millions, and identical. And that the value of his creation —that is to say, his project (understood this eat: design, calculate, development, prototypes and essays of validation)— has a cost of tens to thousands of times the one of one of his units.

These same activities, for the construction of a building, hardly can exceed a 15 % of his value of construction. In which we could consider more repetitive, the houses, only those who do not design them or build think that they are all equal. In reality they are seemed, but never identical. In this field, in the house, achieve the repetition of models to scale industrial will be the only form to absorb the indispensable costs to obtain a product in whose project at all leave at random or opened to distinct interpretations.

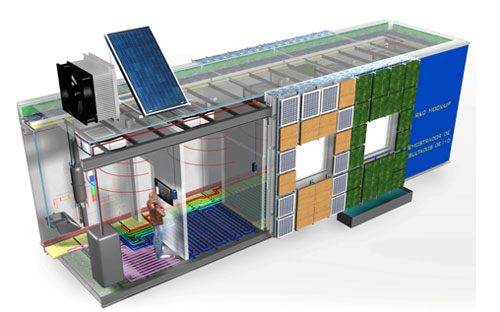

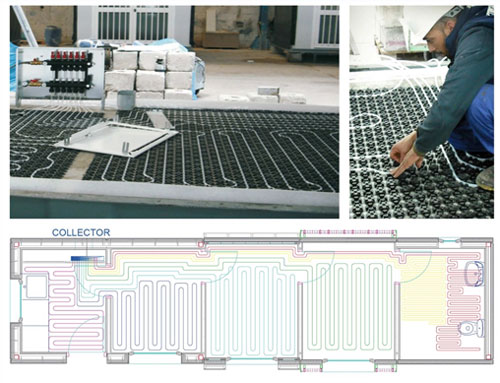

In this sense direct all the programs of R&D in edificación of houses. To title of example will expose the result of a European project, designated I3 WITH, and another Spanish —Inviso—, in whose frames Dragados, with the participation of diverse universities and companies manufactureras Spanish and European, has realised, after four years of studies and essays, a modulate demostrador —without any aesthetic pretence, but yes technical— with the end to show a model that, realised in series, allow to optimise the final costs and the guarantee of the product thanks to the certification of his functional efficiency, structural, energetic and ecological, from the point of view of the consumption and of the of the provision. No only by means of the theoretical fulfillment of some codes, likewise theoretical, but on prototypes checked and modified before the launching of the product. Of course the cost of his project and development is of tens of times the one of his cost of manufacture.

This demonstration is designed based on a self-supporting chassis on which the subsystems constituting the whole apply.The vertical elements of the chassis include what might be called "technical enclosures", i.e., they are all devices and pipes necessary for the functioning of the housing and, in turn, the interior finishes.

In this case, for panels and vertical "frame" has been the panels with G.R.C. (a matrix of mortar reinforced with glass fibre) that incorporates a metallic framework outwards, which placed the different layers of finished "aesthetics" and allow many alternatives, as you can be seen in the photos of the experimental module.

The prototype is equipped with the latest technologies in acquisition, energy saving, waste management and home automation. Several of the systems implemented therein are in turn prototypes developed by the different partners of the project.

By its manufacturing system, adapted to an assembly line for the assurance and certification of their consumption, maintenance and possibilities, both aesthetic and functional variation, this module has all the characteristics of a manufactured product. Only by its appearance and purpose, consider a conventional building.

The development of this type of pilot projects underscores the enormous difficulties which our current systems of construction for the solution of the first two problems mentioned at the beginning of this article: the costs of drafting and development of the project, and the series and terms of execution.

With these programs of research, shows that the time required for the definition of the work and the conduct of tests, tests and verifications of the chosen systems, far exceed deadlines and resources usually employed in the drafting of any conventional. And this, for a small item like the module, so only the repetition of the prototype on the hundred or thousand units (depending on their sophistication) makes possible the amortization of development costs.

Turning to what we call "unique project", numerous amendments and necessary corrections in the process occur simultaneously to its construction; making it impossible to raise it without gaps, both in the physical sense of fit between the different parts of the work, and organizational, as regards time limits and construction systems.

These, by calling them somehow, uncertainties, be solved, for major promotions of identical homes in the implementation of the first units, when the construction period is long and phased and well known building systems. But for representative buildings with new materials and new application systems, time and cost implications can be dramatic as the resolution of the problems must be made on the fly.

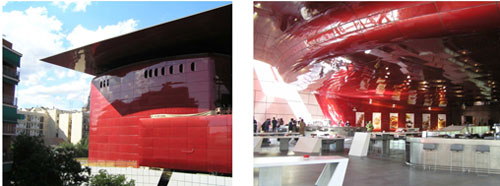

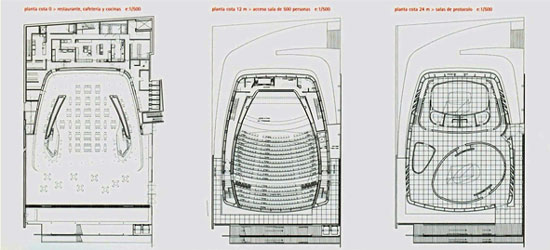

To illustrate this second aspect, the resolution of these gaps and uncertainties, bring you another example: the construction of the facade and interior of polyester coating. In the Auditorium Jean Nouvel in the Museo Reina Sofia in Madrid.

The cost of the engineering needed to develop the definition, models and moulds of the totality of the panels exceeded by far the price laid down for the manufacture of these, that all of the surfaces to be manufactured were regladas, being generated by curves of variable radii, plants and general sections of the project.

This meant that each piece should be defined by using a program which later might be "translated", to another, able to give instructions to a lathe of CNC, fitted with a head roboticized, labrase on a block massif model, or mold of each panel. Total: 1,600 different pieces!

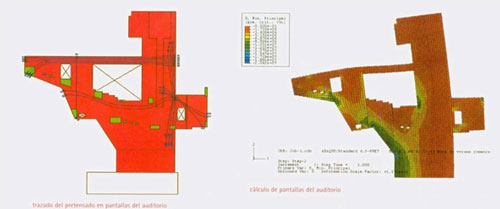

Even ignoring the cost that this would mean, dozens of times the value of the panel, it was impossible to make them all with the resources available on the market in the time limit to finish the work. Even so, and assuming that she is had been able to manufacture all the pieces by some esoteric system, without exact knowledge of the final deformation of the structure support, a semicircular portico with large cantilevered postensados, nothing would have fitted.

The chosen route was as follows:

Unified, as far as possible, the curves that plants and sections, defining different surfaces and, above all, the agreements between them. With the condition that its new radio had to be respected, as well as the general shape of the building, the gaps and channels provided for in the original geometry, as well as all agreements between panels in the form of "tallow-drop".

Then, was an electronic model in CATIA and from lathe of CNC, a physical model that were set, by common agreement with the property, those areas in which it was impossible to carry out panels with theoretical measures tolerances of construction made it impossible to define which dimensions and curves would be needed in the areas of Union between different radio.

Thanks to the appropriateness of the panel finally selected polyester: a sandwich of 40 mm thickness, and the process of review and final painting, could solve the problem. However, in a totally artisan and improvised way:

In all areas of encounters in the façade, the panels were manufactured, according to their theoretical radii of curvature, and larger than necessary. Once mounted adjacent panels, each panel of agreement presented in his position, scoring on the boards. The panel returned to factory where cut along those lines, relaminaban areas of boards and came to the final process of caulking, polishing and painting, to be again sent to work where, already with its exact dimensions are riding.

However, this process was impossible in some, limited and intricate, encounters located in the interior of the building. In these areas had to devise a system for defining the areas of agreement in situ marking the transition between the different levels with flexible rules.

Once defined surfaces and joints of encounter, he came to the cut of the adjacent panels in the same way that the indicated previously. He was a plaster model, also in situ. This model was dismantled and sent to factory where, exclusively for panels located in the interior, it was a finish identical to that of the rest of panels.

In short: 'high tech' appearance achieved with traditional methods, because the term and repetividad of a singular work, practically, impossible get an industrial product.