A ultrarresistente concrete allow manufacture "the lighter market facades"

on January 21, 2011

These are the three main features of this concrete, result of a project of r & d, launched three years ago, which invested more than half a million euros. Their mechanical qualities approximate it the steel and the thickness of the sheets is between one and four centimeters, from which you can build facades of conventional buildings of 12 cm thickness, or 17 inches for ventilated facades. Its weight ranges between 120 and 170 km/m2 respectively.

So thin elements translates into a saving of material and, moreover, allows win in floorspace when constructing buildings as the technical director of Imat, Ferrán Bermejo explains. "Thanks to this little thickness, you can raise the standards of acoustic and thermal insulation of facades that, otherwise, the rules would prevent increase if we work with conventional concretes of 40 or 50 centimeters." "WINS in acoustic and thermal and, therefore, in comfort and energy efficiency". Benefits that, according to Bermejo, put the new concrete in direct competition with other light systems used in industrialized dry construction.

The secret of the lightness of this material is directly linked to its ultraresistencia. So, before concrete which hold about 25 megapascales to compression, and prefabricated parts between 30 and 40, Imat product is in the 140 megapascales.

"At the level of resistance when we analyze the technical features is a material that is halfway between what is a concrete and steel." "Have some peculiarities that resembles more its resistance to compression, bending and its ductility steel", indicates the technical director.

These properties are consequences of the peculiar composition of the concrete, as well as the traditional cement, aggregates and water adds a series of special additives. "Some of them use some type of nanomaterial and aggregates are very selected, with very fine granometrías." "Thus, we get an extremely compact product with very low porosity", said Bermejo.

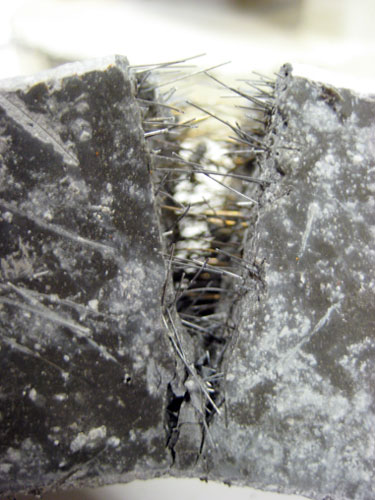

Microfibre by armed

But differences of this concrete are found not only in substances that make it possible, but that the armed nor responds to the traditional fact of steel bars. Instead, Imat researchers use something as small as microfibre of metallic and non-metallic, origin with a length of 15 mm and a tenth of a millimeter in diameter. These dimensions allow them to be "embedded" in the mass of the concrete, according to Bermejo. "Just as in conventional reinforced concrete, the armor is perfectly located in specific points, we have this armor in a diffuse way in all the mass of the concrete".

This property is, in fact, the primary responsibility for the flexibility of this product ultrarresistente and light. Thus, in the Imat succeeded manufacture elements of reinforced concrete a centimeters in thickness which have been able to cut, shape and drill at will.

Bermejo stresses the double value to be drawn from the development of the concrete. On the one hand, the material provides innovations from the structural point of view, which allows the transition to very light structures and the change of concept about reinforced concrete; and on the other hand, it gives rise to a slope more aesthetic of concrete that allows to work with colors, shapes and finishes various giving one aspect and distinct from the buildings.

In this sense, the Universitat Autònoma de Barcelona will host the first practical demonstration of this concrete, which will be incorporated into the construction of a new laboratory in the Bellaterra campus. It will be the first building with ultrarresistente concrete facades. Also, the Center will present several closures of façade and structural components in the next edition of the Construmat exhibition, to be held during the month of May.

Research, supported by ACC1Ó, the internationalization of the Catalan company Innovation Agency, has counted with the collaboration of the Department of engineering of the construction of the Universitat Politècnica de Catalunya (UPC) and the laboratories of Cecam (Center of studies of the construction and analysis of materials SLU). IMAT has worked in this line of research since 2007 and patented technologies and products which are derived, as well as market licences to companies for their use.