Historia, clasificación, transformación, reciclado, maquinaria, tecnología y aplicaciones

Los áridos

César Luaces, director técnico de la Asociación Nacional de Empresarios Fabricantes de Áridos (Anefa)22/01/2010 22 de enero de 2010

La industria productora de áridos, es decir, arena o rocas fragmentadas, actualmente es uno de los subsectores básicos de la minería española y mundial. Sin los áridos no sería posible la construcción de viviendas, oficinas, aeropuertos, hospitales, calles, carreteras, autopistas, vías de ferrocarril y puertos, ni se podría disponer de muchos productos industriales de uso cotidiano.

Los áridos son materiales granulares inertes formados por fragmentos de roca o arenas utilizados en la construcción (edificación e infraestructuras) y en numerosas aplicaciones industriales. Coloquialmente son conocidos como arena, grava y gravilla, entre otros.

Cada español consume, sin ser consciente de ello, 11.650 kilos al año, es decir, aproximadamente 150 veces su peso. Prácticamente todo lo que una persona puede observar a su alrededor procede de una cantera o de una mina, a excepción de lo proveniente de los mundos vegetal y animal (muebles, tejidos...).

Normalmente, a causa de sus características y los grandes volúmenes que se utilizan, los áridos se comercializan a granel en camiones con caja (conocidos como 'bañeras' vistos con mucha frecuencia por carreteras). Los áridos son materias primas minerales indispensables para la sociedad. En general, se trata de materiales baratos y abundantes que se explotan necesariamente cerca de los centros de consumo, con el fin de reducir los costes de transporte.

En función de la aplicación a la que están destinados, los áridos deben reunir características diferentes, asociadas a su naturaleza petrográfica o al proceso empleado para su producción, entre las que cabe destacar:

- Propiedades geométricas: tamaño, forma de las partículas (por ejemplo, si son alargadas o no), caras de fractura, calidad de los finos, etc.

- Propiedades mecánicas y físicas: resistencia al desgaste (por ejemplo, para que los coches no se deslicen en las carreteras), resistencia a la fragmentación, resistencia al pulimento, densidad, porosidad, contenido en agua, etc.

- Propiedades térmicas y de alteración: resistencia a los ciclos de hielo y deshielo, etc.

- Propiedades químicas: contenido en azufre, cloruros, materia orgánica, contaminantes ligeros, reactividad potencial, etc.

Estas propiedades se evalúan gracias a un conjunto de más de 50 normas de ensayo y de especificaciones comunes a todos los países de la Unión Europea.

La idoneidad del control de producción que desarrollan las empresas es verificada periódicamente por organismos notificados independientes, emitiendo un certificado acreditativo. Gracias al control del proceso, se dispone de productos de calidad contrastados, tras el sometimiento continuo de los áridos a ensayos de laboratorio, que permiten determinar si sus propiedades cumplen con los requisitos de las aplicaciones en los que se van a emplear, lo que implica que los procesos de fabricación estén perfectamente controlados en sus diferentes etapas. Desde el 1 de junio de 2004, los áridos deben llevar obligatoriamente el marcado CE tanto para su comercialización como para su uso. Por lo tanto, todo usuario tiene el derecho y el deber de solicitar la existencia de dicho marcado en los áridos, como indicador del cumplimiento de los requisitos esenciales establecidos por la Unión Europea.

Los áridos, para las aplicaciones como el hormigón o las carreteras, están regidos por reglamentos técnicos oficiales conocidos como EHE (instrucción para hormigón estructural) y el PG-3 (carreteras).

Actualmente, numerosas empresas del sector cuentan con registro de empresa de los sistemas de gestión de la calidad, según la norma UNE en ISO 9001-2000. Hoy en día, están desarrollándose marcas de calidad para los áridos.

Clasificación

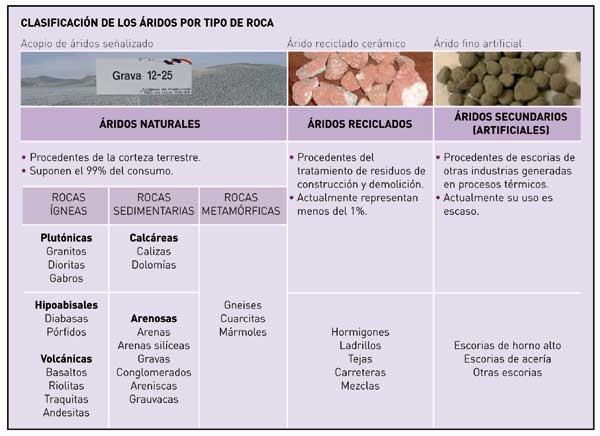

Los áridos pueden clasificarse por el tipo de roca del que proceden, por la aplicación a la que están destinados y por su tamaño.

Por tipo de roca

En función del tipo de roca, los áridos pueden clasificarse en las categorías de la tabla siguiente:

Los áridos naturales pueden obtenerse:

- De yacimientos detríticos no consolidados, tipo arenas y gravas, en explotaciones denominadas graveras.

- Mediante la trituración de rocas masivas y consolidadas tipo granito, diorita, calizas, cuarcitas, en explotaciones denominadas canteras.

Los áridos pueden presentar formas redondeadas, cuando se trata de materiales aluviales que no son sometidos a trituración, o angulosas en el resto de los casos donde existe trituración.

Por tipo de aplicación

En función de su aplicación, los áridos pueden clasificarse en las categorías de la tabla siguiente:

Por tamaños

En cuanto al tamaño, los áridos se designan mediante la fracción granulométrica d/D comprendida entre el tamaño inferior (d) y el tamaño superior (D), por ejemplo, un árido 6/12 milímetros.

Un recorrido por la historia

Desde la antigüedad, los áridos han acompañado el desarrollo de la civilización humana. En efecto, desde el inicio de los tiempos, el hombre ha utilizado materiales naturales para la construcción de su hábitat y la ordenación de su entorno.

En el periodo que comprende desde la antigüedad hasta la Revolución Industrial del siglo XIX, la producción de áridos se realizaba artesanalmente recurriendo a medios manuales, rompiendo y triturando las rocas con herramientas rudimentarias como mazas o martillos.

Para evitar su transporte, los áridos se producían en las proximidades del lugar donde iban a utilizarse. En esa época, una persona podía llegar a producir 125 toneladas al año. El final del siglo XIX supuso una revolución en el arte de la construcción, gracias a la aparición del cemento industrial y del hormigón. En esa misma época, la creación de las redes de ferrocarril, de la infraestructura de carreteras y de las obras públicas necesarias para franquear obstáculos, requirió el uso de grandes cantidades de materiales nuevos y económicos.

Comienza entonces el verdadero auge de los áridos como sector productivo, dependiente en gran medida de la actividad constructora.

A lo largo del siglo XX, fueron desarrollándose nuevas tecnologías que permitieron incrementar las producciones mediante la incorporación al proceso de maquinaria fija y móvil, cada vez con mayor capacidad. De este modo, ha ido creciendo el tamaño de las explotaciones de áridos a cielo abierto, denominadas canteras y graveras. Hoy en día, una explotación moderna puede llegar a producir más de un millón de toneladas al año con, aproximadamente, una docena de trabajadores.

Evolución

A principios del siglo XXI, la industria extractiva de los áridos destaca como uno de los sectores mineros más importantes, a la hora de proveer a la sociedad de recursos naturales primordiales para el desarrollo económico. La profesionalización creciente es una de las metas de las empresas pertenecientes a este sector, que aplican, cada vez más, tecnologías innovadoras para optimizar y controlar los procesos.

En la actualidad, la producción de áridos se realiza en el marco de un desarrollo sostenible, procurando obtener productos de calidad con la consideración del medio ambiente y la prevención de riesgos laborales.

Procesos de transformación y reciclado

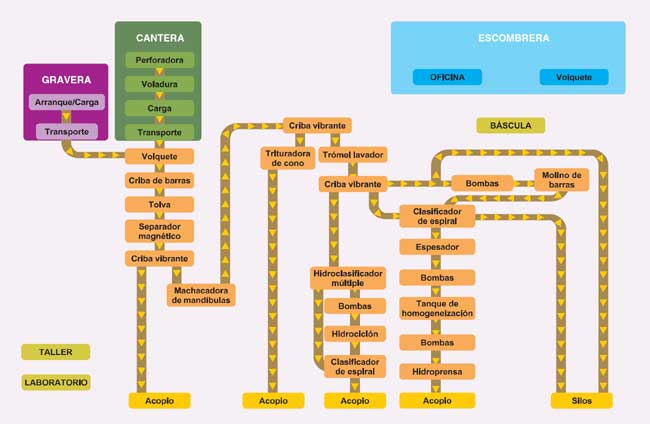

El proceso de tratamiento de los áridos permite obtener productos terminados aptos para el consumo. Se trata de un proceso muy automatizado y tecnológicamente complejo, pues intervienen en él una gran cantidad de disciplinas. Sin embargo, en cuanto a su principio básico, puede decirse que es sencillo, ya que consiste en triturar el todo-uno procedente de la explotación para obtener tamaños menores y clasificarlos con el fin de almacenar por separado cada granulometría. En algunos casos, es necesario lavar el material para mejorar sus características. Las etapas básicas son:

Esquema de explotación de los áridos.

La trituración y la molienda

La trituración y la molienda permiten disminuir, en sucesivas fases, el tamaño de las partículas, empleando para ello equipos de trituración de características diferentes como los de mandíbulas, los de percusión, los giratorios o los molinos de bolas o de barras. En las arenas y gravas de origen aluvial, únicamente se trituran los tamaños superiores y, por lo tanto, el número de etapas de trituración suele ser inferior.

La clasificación

Entre las etapas de trituración, aparecen intercalados los equipos de clasificación, las cribas, que permiten seleccionar el tamaño de las partículas separándolas entre las que pasan y las que no pasan por las mallas. De este modo, se logran áridos de todos los tamaños posibles, en función de la demanda del mercado.

Esquema de una criba.

El lavado

Las operaciones de desenlodado y lavado del material se realizan cuando el yacimiento presenta lodos, arcillas u otras sustancias que afecten en la calidad de los áridos, y permiten obtener áridos limpios con el fin de responder a las necesidades de determinadas aplicaciones de la industria, evitando así la alteración de la adherencia con los ligantes (cemento, cal, compuestos bituminosos u otros) permitiendo así proceder a su correcta aplicación.

El almacenamiento

En la etapa de almacenamiento, gracias al control del proceso de fabricación, ya se dispone de productos de calidad clasificados según su granulometría, que se almacenan en silos o en apilamientos a la intemperie o cubiertos, llamados acopios.

El reciclado de residuos de construcción y demolición

En ciertos casos, puede ser posible la realización de labores de reciclado de residuos de construcción y demolición (RCD) o de vaciados de obras procedentes de la construcción, de la demolición de estructuras y edificaciones o de la obra civil (túneles).

De los RCD mencionados pueden obtenerse áridos reciclados aptos para ser consumidos, siempre y cuando cumplan los requisitos de calidad exigibles para cada una de las diferentes aplicaciones. Para ello, es muy importante que el residuo haya sido seleccionado en origen, de manera que se evite la mezcla de materiales no deseados, que perjudican la calidad del producto final.

Maquinaria y tecnología

El proceso de producción de áridos requiere el empleo de una maquinaria muy robusta, resistente y de grandes dimensiones, para poder manipular los grandes volúmenes de materias primas que demanda la sociedad. La obtención de áridos con las características de calidad requeridas por el mercado, es posible gracias a que los sistemas de control empleados son cada día más completos y automatizados y permiten, en todo momento, regular la producción.

Equipos de arranque y carga

Las operaciones de arranque y carga se realizan en canteras y graveras, fundamentalmente con equipos móviles como palas cargadoras sobre ruedas, excavadoras (frontales o retros) y bulldozers, además de perforadoras y dragalinas.

La perforadora realiza, en las canteras, los barrenos que se rellenan con el explosivo necesario para la voladura. La pala cargadora es un equipo de carga muy versátil por su gran movilidad y fácil maniobrabilidad, que se utiliza, sobre todo, en el movimiento de tierras, ya sea en la descubierta o en la restauración, en la carga en el frente y en la carga en el parque de áridos de dumpers, camiones y tolvas de alimentación. La excavadora hidráulica es un equipo de excavación y carga ampliamente utilizado que puede ser de arranque frontal, o retro. Se utiliza en la excavación de tierras, en el arranque de materiales no consolidados y en la carga de materiales en dumpers, camiones y tolvas de alimentación.

La dragalina permite extraer el material cuando se encuentra por debajo del nivel del agua. Está formado por un cazo que se encuentra suspendido de una pluma por medio de cables, que permiten lanzarlo vacío y recogerlo con el material escurrido. Por último, el bulldozer o tractor se utiliza en el arranque, empuje y apilado del material para su posterior carga y transporte, en el desbroce del terreno y en el empuje y extendido de material de relleno, sin olvidar labores auxiliares como apertura, nivelación y limpieza de pistas.

Equipos de transporte

Las operaciones de transporte en canteras y graveras se realizan con el dumper o con el camión. El dumper, o camión volquete (rígido o articulado), es el principal medio de transporte sobre ruedas dentro de una explotación de áridos y también en la obra pública. Su utilización se centra en el transporte de material cargado en el frente hasta su punto de vertido en tolvas, acopios intermedios o escombreras.

El otro vehículo de transporte, el camión, es similar al dumper pero de menores dimensiones y capacidad de carga. Al igual que éste, se emplea en el transporte interno de material cargado en el frente hasta su punto de vertido, ya sean tolvas, acopios intermedios o escombreras, y además en el transporte externo por carretera para distribuir los productos a los usuarios finales.

Equipos de la planta de tratamiento

Entre los equipos fijos de proceso utilizados en una planta de tratamiento de áridos cabe citar las tolvas, los alimentadores, los equipos de trituración y molienda, las cintas transportadoras, las cribas, los silos, los equipos de lavado, los motores y bombas, la instalación eléctrica y los sistemas de control.

La creciente aplicación de los criterios ligados al desarrollo sostenible en las explotaciones permite mirar al futuro, con la confianza de poder afrontar los nuevos retos que demanda la sociedad. Desde el inicio de la explotación hasta su clausura, las empresas que producen áridos deben aplicar una serie de técnicas para prevenir o minimizar los efectos de la actividad sobre el medio ambiente.

Sistemas y equipos para la protección del medio ambiente

La creciente aplicación de los criterios ligados al desarrollo sostenible en las explotaciones permite mirar al futuro, con la confianza de poder afrontar los nuevos retos que demanda la sociedad. Desde el inicio de la explotación hasta su clausura, las empresas que producen áridos deben aplicar una serie de técnicas para prevenir o minimizar los efectos de la actividad sobre el medio ambiente.

La implantación de estas medidas dependerá de las circunstancias concretas de cada explotación, ya que es difícil hablar de actuaciones universalmente aplicables. La variedad de equipos y técnicas disponibles es muy amplia por lo que, como ejemplos, pueden citarse:

- Sistemas de control del polvo (aspiración, filtros de mangas y pulverización de agua).

- Sistemas para la protección frente al ruido (pantallas y carenados).

- Minimización de residuos, recogiéndolos selectivamente para una correcta gestión.

- Depuración del agua de lavado, por sedimentación de sólidos en balsas o en tanques espesadores, o por filtrado.

- Apantallamiento de la explotación para reducir el impacto visual.

Además, la restauración o recuperación de los terrenos explotados, que es la última fase del proceso productivo, tiene por objetivo reacondicionar los terrenos en conformidad con unas directrices de calidad medioambiental, con el fin de devolver el área a su entorno. La legislación sobre restauración obliga a las empresas a:

- Disponer de un proyecto de restauración de los terrenos aprobado por la autoridad competente.

- Depositar un aval que garantice la realización de ese proyecto.

Aplicaciones y usos de los áridos

Los áridos se emplean en cantidades considerables en todos los ámbitos de la construcción, ya sea en viviendas, obras de infraestructura, vías de comunicación, equipamientos o industria. Sin embargo, esta materia prima no es nada conocida por el gran público quien, normalmente, utiliza o adquiere los bienes ya terminados donde esta materia prima ya está integrada y no en su estado natural.

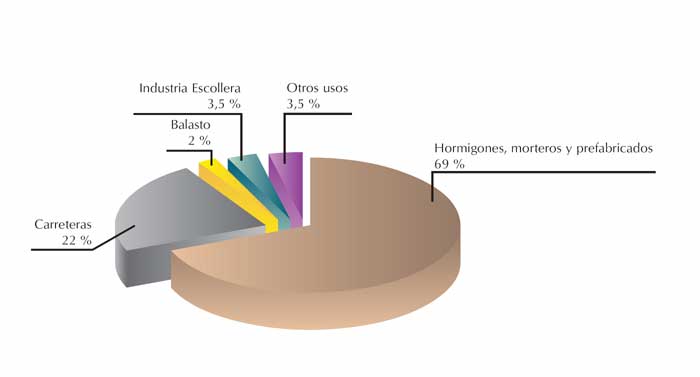

El uso de los áridos en la construcción

Los áridos son la primera materia prima consumida por el hombre después del agua. Basta decir que cada persona consume en su vida cerca de 850.000 kilos de áridos, más de 10.000 veces su peso, cantidad equivalente a la transportada en 32 camiones bañera. Ya se trate de una autopista, aeropuerto, o vía de ferrocarril, las técnicas constructivas requieren cantidades ingentes de áridos. El balasto para las vías férreas, los cimientos de las edificaciones, las distintas capas, -ligadas o no ligadas-, que forman las carreteras son esencialmente áridos.

Aplicaciones de los áridos en construcción.

Las principales aplicaciones en construcción son:

- Morteros; empleados para unir ladrillos o revestir paredes. 1 metro cúbico de mortero contiene 1,3 toneladas de áridos.

- Hormigones; que pueden ser estructurales (cimientos, vigas y pilares) o en masa (pavimentos, etc.). Para la fabricación de 1 metro cúbico de hormigón son necesarias entre 1,8 y 1,9 toneladas de áridos.

- Prefabricados; como ladrillos, bloques, vigas, bordillos, aceras y tuberías, entre otros.

- Bases, subbases y aglomerados asfálticos; que son los elementos que componen las carreteras, autovías, calles, aparcamientos o pistas. Para 1 kilómetro de autopista son necesarias unas 30.000 toneladas.

- Balasto; para construcción de vías férreas, y sobre el que se apoyan las traviesas y los raíles. 1 kilómetros de vías de ferrocarril requiere unas 10.000 toneladas de áridos.

- Piedras y bloques de escollera para puertos.

- Y otras aplicaciones como: presas, puentes, aeropuertos, calles, centros comerciales, parques de ocio, viviendas, recintos feriales, edificios singulares, rascacielos, túneles y universidades.

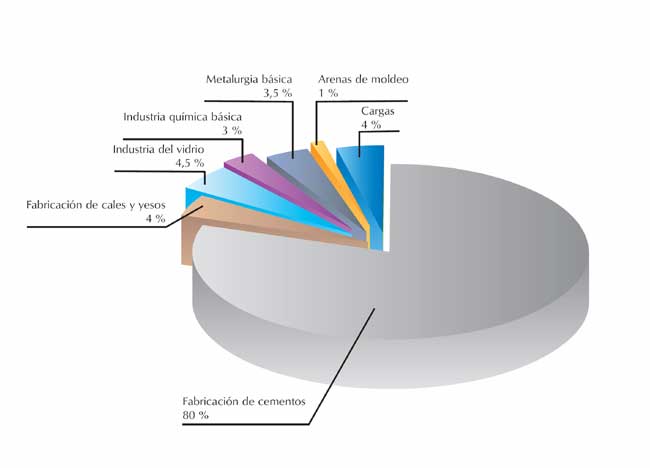

Las aplicaciones industriales

Además de estar presentes en la construcción, los áridos también se encuentran en innumerables elementos de la vida cotidiana. Es sorprendente descubrir cuántos objetos habituales han sido fabricados con áridos y en cuántos procesos industriales se emplean. Asimismo, los áridos tienen diversas aplicaciones para mejorar el medio ambiente: reducción de las emisiones de azufre y de la acidez de los suelos y filtros para la depuración de aguas, entre otras.

Los áridos destinados a usos industriales requieren unas propiedades muy específicas, como una mayor pureza en cuanto a su composición química, y un tamaño muy pequeño (micronizado), obtenido a través de la molienda fina de los materiales.

Aplicaciones industriales de los áridos.

- Fabricación del cemento. El 80 % del cemento es caliza.

- Industria de la cerámica y vidrio. 1 tonelada de vidrio requiere 700 kilos de arena de sílice muy pura, 300 kilos de dolomía y caliza, y 130 kilos de sosa.

- Fabricación del acero. La caliza se emplea como fundente.

- Materiales abrasivos.

- Industria papelera. 1 tonelada de papel contiene unos 300 kilos de carga mineral.

- Industria de los plásticos.

- Industrias de pintura y detergentes. La caliza se emplea como carga en pinturas e incluso como pigmento. En la fabricación de detergentes, interviene la arena silícea.

- Industria informática. La arena silícea permite la fabricación de componentes de los ordenadores.

- Industrias químicas y farmacéuticas. La caliza finamente molida interviene en la composición de numerosos productos químicos como la pasta de dientes, cosméticos o medicamentos.

- Tratamiento de aguas. Filtración de aguas de consumo humano, depuración de aguas residuales y neutralización de aguas ácidas.

- Producción de energía eléctrica. Cargas para centrales térmicas, desulfuración de gases y presas para energía hidroeléctrica.

- Alimentación. Para fabricar 100 kilos de azúcar, son necesarios 20 kilos de caliza. También se emplea en el proceso de fabricación del pan, del vino y de la cerveza.

- Otras aplicaciones industriales. Usos agrícolas, corrección de suelos, fertilizantes, aditivos para piensos, lechos filtrantes, revestimientos aislantes y refractarios.