Why a concrete structure deteriorates?

January 21, 2010

When inspections are carried out in concrete after some time of life for this, it can be considered a durable material. In fact, if it is located in appropriate conditions, concrete, like wine, improves over time; their resistance is growing gradually, albeit at a speed lower than at the beginning; its porosity will decline at the same speed which increases the resistance. However, due to a number of factors, the exposed concrete presented a series of factors of deterioration, and here comes the need for the repair of concrete structures.

Deterioration of concrete

The root causes of the damage and deterioration in the concrete are numerous and varied origins, chemical and physical, including other causes such as design, bad execution errors during construction or effects of aging.

Damage to chemical attacks

As a reminder, it is important to note that, from a chemical point of view, the concrete is alkaline in nature. Therefore, it is particularly vulnerable to the attack by acidic substances in the environment or which is exposed in their lifetime.

The most common decay in a reinforced concrete structure is not due to a chemical attack to the same concrete, but other component that is, the steel armor. This armor is protected by the concrete surrounding, that provides the alkalinity needed to avoid corrosion. However, under certain conditions, such as the marine environment or the action of deicing salts, chlorides can penetrate concrete until the armor. With the presence of oxygen, in addition to the sufficient amount of ions chloride dissolved in water in the pores of the concrete, the corrosion of the armor, even under conditions of high alkalinity can instigate. In these circumstances can produce cracks and weaknesses in the thin layer pasivante of oxide on the surface of the steel, due to the formation of hidroclorídricas salts. So you can start corrosion (pitting) points. Under certain conditions, these points of corrosion can grow quickly and cause a great loss of section with serious structural implications.

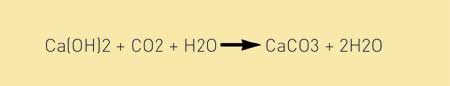

The second most common cause of deterioration due to chemical attack is the natural phenomenon of carbonation. The concrete is almost always in contact with air, and therefore, depending on the location of the structure, exposed to minors or higher levels of carbon dioxide in the atmosphere. In the concrete made with ordinary Portland cement, the portlandita is present in relatively high amounts (40 to 50 per cent). Free concrete lime is vulnerable to the reaction with carbon dioxide from the air that is dissolved in the water in the pores of the concrete, creating calcium carbonate on the following reaction:

One consequence of the carbonation is the decrease in the pH of the concrete from 13, when it is new and not carbonated, up to 9 after the process. The 'front' of carbonation, which marks the depth of penetration of carbon dioxide and the consequent reduction in alkalinity pasivante, can eventually reach the depth of the armor. In this situation the steel is no longer "naturally" protected by the high alkalinity of the concrete, and with the presence of normal oxygen and humidity, corrosion, will occur leading to crack and shedding of the lining of concrete.

Sulphates are always present in the cement and form the etringita (needle-shaped crystals) during the early stages. This is mainly due to the gypsum (calcium sulfate) added on the ground of cement, which reacts with the aluminates cement (regulators of setting), during the first hours after the knead with water for the production of concrete.

Expansive operators from sulphates are also often add when concrete or mortar with compensated shrinkage.

Damage in concrete by reactions with sulfate arise when additional sulphates penetrate into the concrete or when there is a later addition of sulphates (e.g. by arid contaminated with sulphates). This phenomenon is called delayed formation of etringita and secondary etringita. It occurs a heterogeneous and much later (after months or even years). These expansive reactions can also produce crack, detachments of the concrete and loss of resistance, given that they occur when the concrete is already hardened and a rigid body.

This is a reaction of reactive siliceous aggregates with alkaline constituents of the concrete, in the presence of water. The ASR was identified for the first time and cause of the deterioration of the concrete for over 60 years (Stanton, 1940). Since the original discovery, many cases all over the world have known (sometimes known emotionally as 'concrete cancer').

It is widely accepted that the three components needed to ensure that there is the ASR in a concrete structure are:

- Reactive silica (of aggregates).

- Alkali enough (mainly of Portland cement, but also of other constituents of the concrete).

- Sufficient moisture.

In the first stage, alkali from mainly cement, migrate to the aqueous solution of the pores and come into contact with reagents, forming an alkaline siliceous gel aggregates.

In a second stage of the reaction, this gel siliceous reacts with the free lime in concrete, to form a new type of gel which can absorb a large amount of water, and therefore has great properties of swelling. This swelling effect generates forces of expansion in the hardened concrete. Typical damage by ASR models appear in the form of a fissured surface superficially with capricious ways. But this crack propagates into the interior of the concrete with the time, and the expansion continues indefinitely while the water continue absorbing reactive gel.

The sea water is a major source of chlorides which can attack the concrete. His attack comes from a more or less simultaneous reaction of sulfates, chlorides and other constituents of cement (C3A & Ca (OH) 2). Salts of magnesium in water Navy are the most aggressive. The cause of degradation remains mainly the formation of etringita generated by the expansion of the concrete, giving rise to crack. The attack begins from the surface and penetrates over time into the heart of the structure. The areas most at risk in marine structures are those located in the area of tidal race, as the mechanical action of the waves is added to the chemical reaction, eliminating more damaged concrete, and providing access to more of chlorides (apart from the injurious effect of the cycles of sequedad-humedad).

Clean or soft water produces a less common attack, but that can happen particularly in mountainous areas or with acidic water conditions / soft field, for example in areas with very dense such as granite rocks, or at the bottom of the slabs in bridgeswhere condensation may occur. The attack by soft water damage due to the deslavado of the portlandita and free of the matrix of cement lime.

Deterioration due to physical causes

The concrete is made of cement, aggregates and water. Properties of hardening due to hydraulic cement capacities. It is therefore natural that the hardened concrete is influenced by the presence or action of the water (free or tied in its own structure, as well as their interaction with external sources of water).

The concrete can be damaged due to uncontrolled retraction. The retraction is a physical-chemical phenomenon always occurs in cement materials, and begins at a young age (some retraction occurs even before the concrete has hardened) and continues gradually to the last stages of hardening, for a long time.

The main visual effect due to retraction is the formation of cracks. These cracks may appear, or very soon after having poured concrete (e.g. cracks of settlement, produced nothing but remove the formwork) or after several days, weeks or months, due to the behavior in the long term of the retraction.

This deterioration occurs mainly in countries or areas subject to conditions of winter extreme and the damage is can accentuate the presence of de-icing salts, used in bridges, for example, to reduce the formation of ice on the roads. These damages are caused by inappropriate design of the concrete, does not contain enough scattered pores in it to provide enough space so that the water expand when it swell to be frozen.

The main symptoms of these damages are detachment of chunks of concrete and apparent swelling from other parts of the structure, along with formation of surface crack. When this occurs in an extreme way, the structure can be almost destroyed.

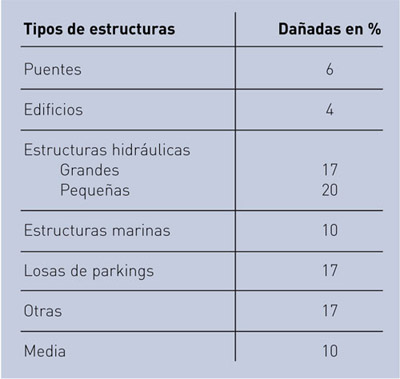

As an example, an investigation carried out in the United Kingdom in 1997 showed that more than 10% of all structures of reinforced concrete had some damage due to cycles hielo-deshielo (including 6% of the bridges).

Damage from other causes

There are many other causes that can cause damage in concrete structures, which can include accidental damage (e.g., vehicle crashes), abrasion by traffic or abrasion by liquid circulating. Other important causes not detailed here may be the inappropriate design of the concrete, bad implementation or monitoring in commissioning work, calculation errors, poor placement of the armor, the nests of gravel by inadequate vibration and compaction or damage resulting from fire.

Evaluation of the conditions of the structure

It is obvious that there are so many possible causes of deterioration, it is necessary to carry out an assessment of the conditions of the structure by qualified personnel, to establish the correct diagnosis. The assessment can determine, for example, the level of risk of corrosion in the structure by means of a 'mapped' to identify areas with high potential of corrosion; the measure of the depth of the front of carbonation by means of the control of the pH, using an indicator solution of fenophtalein; the extent of the content of chlorides to the level of armor, and verification of the porosity of concrete and its resistance to compression.

If it is not this assessment of the concrete in an appropriate manner, it may be counterproductive in the long term, given that the causes of damage and deterioration that are not taken into account in the strategy of repair can lead to the repair is made fails or the concrete continues to deteriorate in another part of the structure.

Repair: objectives, selection of materials and application techniques

Once the assessment of the current situation was properly made, the objectives of the repair can be defined and the selection of materials be made. The results of the evaluation can be you can choose several options:

- Not do anything.

- Temporarily scrap the capacity of the structure.

- Prevention or reduction of further deterioration.

- Structural reinforcement.

- Reconstruction of part or all the structure.

- Demolition of the structure.

Some of the factors to consider when considered the different options are as follows:

- The use you want to give, and the cycle of life in service.

- The number and cost of acceptable repair cycles during the life of design structure.

- The appearance of the repaired structure.

- The consequences of the structural failure.

- Health and hygiene requirements.

- The need for future inspections and maintenance.

Based on these considerations and the specific characteristics of the work (ease of access, time allowed closing...) as well as environmental conditions, can take decisions on the selection of materials and application techniques.

Surface preparation

Application

Sika develops, manufactures and commercialises systems and specific solutions for the construction, in edificación and civil work - in the fields of the repair and protection of the concrete, the sealed of boards, the impermeabilización structural and the hit rigid and elastic of distinct elements - and in the industry, in the sectors of transport, automotive sector, marine and appliances and equipment.

All over the world Sika supplies products for repair of concrete that fulfil the different exigible rules, between them, in Europe, the IN-1504. For the mortars of repair, establish four categories of the same, of agreement to a series of provision: R4 and R3 for structural repairs and R2 and R1 for repairs no structural (cosmetic). The provision of the products remain differentiated of agreement to his properties, such like resistance to compressesion, adherencia, etc., low different situations (freezing, cycles ice-thaw, immersion etc), in addition to by his module of elasticity. Sika Can supply all the notable materials of agreement to each classification and method of application.