The concrete and the sea

May 6, 2011

Concrete is one of the building materials used throughout the world. This is due to its good structural properties, ease of manufacture and low cost. However, there are some important deficiencies in the properties of the concrete, as the low resistance to traction and porosity. The emergence of internal pores in the concrete is due to the nature of it. It's a material which is the direct product of hydration processes that involve the reaction between cement and water. In all cases, the remains of water in the concrete, once hardened, become pores of various sizes, much will be capillary pores. These pores are connected each other, either directly or through the pores of the gel.

A high volume of pores determines a greater transport of fluids such as water or gas, and also by other chemical substances normally carried by the previous, and that are potentially harmful to the concrete. In this way a fairly slow process of deterioration of structures composed of this material can be started.

The distribution of the size of the pores is fundamentally linked to type and speed of the mechanisms of transport and fixation in relation to the water. The pore size range comprises several orders of magnitude in the pulp of cement, and can be classified in pores of compaction, pore of stationary air, capillary pores and pores of gel [5].

Concrete exposed to seawater can deteriorate due to several factors: the chemical aggression of the constituents of the same on the products of hydration of cement, notably sulphate and magnesium, to expansion due to alkali-aggregate reaction, if there is a dry reagent, the pressure of crystallization of salts in the concrete, to the action of ice in cold climates, the corrosion of reinforcement and physical erosion due to wave. These actions produce an increase in the permeability of the concrete, Nau21 process [6].

Permeability in concrete

Permeability is the property that measures the ease that has a material to be pierced by a fluid due to the existence of a pressure gradient between two sides of the same. In the case of concrete, and in the case of the marine environment, where there is a large concentration of aggressive chemicals in the water, permeability represents a potential risk of significant deterioration. Therefore, in order to reduce the likelihood of being attacked by aggressive substances, reduce permeability of the concrete, intrinsically related to the porosity of the same. The desired reduction can be achieved in various ways, either lowering the total volume of the pores, either reducing the volume of the pores of larger size (permeable pores). Supplementary materials such as fly ash or silica smoke are very well known for its ability to effectively reduce the total volume of the pores.

In this sense, the Spanish instruction of concrete structural EHE-98 [7] requires, for the marine environment, using less than 0.5 water/cement ratio concrete, over 325 kg/m cement content3, the use of a cement of features resistant to this type of environment (MR o SR) and more than 45 mm coating. The requirements of other regulations are similar or even more restrictive. In this way presupposes a concrete waterproof and durable enough to the aggressive actions of the marine environment.

The objective of the work is studying with experimental contrasting which is the variation of pore distribution that occurs in different concrete to provide several additions to the cement, as well as to investigate the influence of the porosimetría in the behavior of the material to transport caused by a pressure gradient.

Experimental method

Materials used

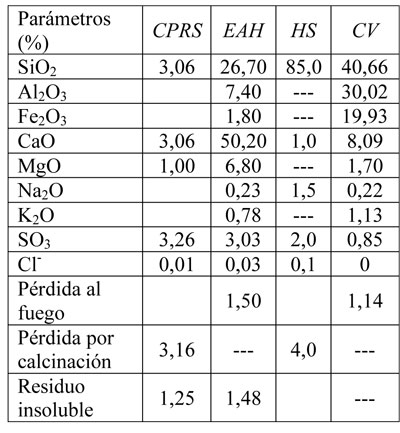

In this study the concrete were built with two types of cement sulforresistentes: cement cement with slag of blast furnace CEM III/B 42.5 L/SR (EA) and pure Portland CEM I 42.5 R/SR (CPRS). These two cements are used in the dosage of four concrete, one for each type of cement, more two others using CEM I 42.5 R/SR (CPRS) along with additions, one in which cement was replaced partially by 20 per cent of ashes ruffles (CV) and another 10% smoke of silica (HS) was used in the, within the limits that allows the current regulation of structural concrete [7]. The chemical and physical properties of the materials used are shown in table 1. The arid fine employee was siliceous River sand while the dry bulk was limestone crushed with a maximum size of 20 mm. In order to achieve a proper workability joined the superplastificante mixture of high-performance (Sika Viscocrete 3425).

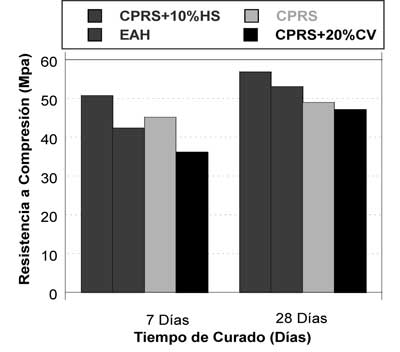

The dosage and preparation of the test tubes

The concretes are dosificaron using the method of la Peña. All mixtures, used a content of cement of 380 kg/m3 and a water/cement 0.45 relationship. In the case of concrete with addition of fly ash and silica smoke followed the recommendations of the EHE-98 [7] for the additions, replacing the content of cement C by C+KF, as well as the A/C for A relationship / (C+KF), being F content addition and K is the coefficient of effectiveness. Coefficient of efficiency used has been K = 2 for silica smoke as K = 0,3 for fly ash. The water/material resulting cementicio ratio is low, and to get a proper consistency added superplastificante in a variable amount between 0.6 and 2%, depending on the case. Table 2 shows details of dosages set forth in the plan of trials.

For the manufacture of all the mixtures of concrete followed the procedure described in standard ASTM C 192 [8]. For each type of concrete made four amassed, and each one of them shaped 14 test of cylindrical tubes of 150 millimeters in diameter and height 300.

Results

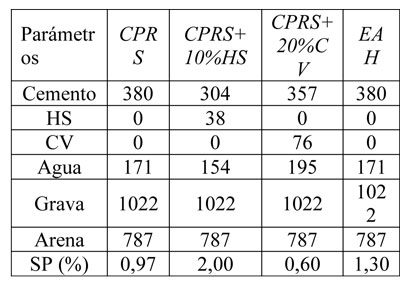

Characteristics of fresh concrete

Table 3 shows the consistency, the content of occluded air and the weight of each of the four amasadas of concrete. The consistency values are indicative of the workability of the mix. Due to the low water/material cementicio ratio, and especially in the case of substitution of part of the cement by additions, mixtures out very dry, so different laboratory tests provided an additive superfluidificante to adjust dosages with a proper workability. The reduction of workability for input of additions was more pronounced in the kneaded of CPRS + 10% HS that elsewhere, so it had to incorporate as many superplastificante in this case. This is due to the greater specific surface area of the particles of silica, on the fly ash smoke or the same particles of cement.

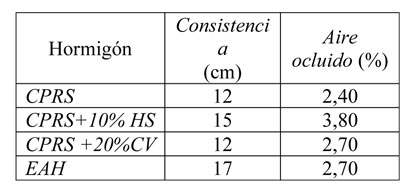

Mechanical resistance

Figure 1 shows the development of the compressive strength of various concretes at the ages of 7 and 28 days. The trial was conducted according to the norm UNE-EN 12390-3: 2003. In the first 7 days seen in the kneaded with silica smoke development of compressive strength significantly higher than in the rest of amasadas. This indicates that smoke from silica improves resistance to compression at an early age, data that is consistent with the properties that is universally attributed to this addition. This improvement also keeps 28 days since the resistance of the mixture with smoke of silica, followed by the concrete with slag of blast furnace remains higher. The explanation lies in these additions Pozzolanic activity. Slower resistance development looms in the mixture of fly ash in any other, because the Pozzolanic fly ash activity is slow. It is important to note that a period of 28 days may not be sufficient for the development of maximum resistance for mixes with mineral additions compared to cement control (pure Portland cement), especially in the case of the fly ash.

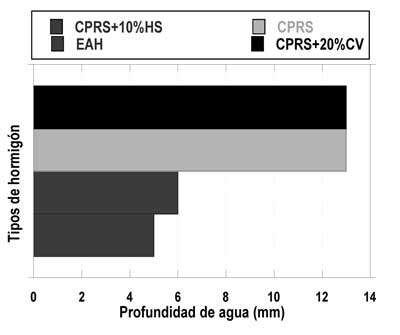

Depth of penetration of water under pressure

In order to check the ease of introduction of water on various concrete was the trial of depth of penetration of water under pressure on two test tubes dosage according to UNE-EN 12390-8: 2001. According to the EHE [7] the average depth of penetration of water must be less or equal to 15 m, while the maximum depth of penetration of water must be less than or equal to 25 m. In all trials met these limitations, so all the concrete may be considered of sufficiently waterproof according to this standard.

The results are presented in Figure 2. In all cases, the depth of the penetration of water in the test tubes made of silica and EA smoke was lower than in the rest. Studied concrete are grouped in its response to the penetration of water under pressure in the same way that make it to the resistance to compression.

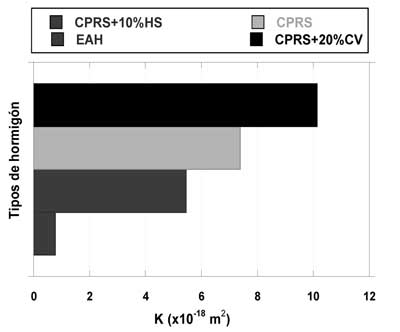

Permeability to oxygen

The trial of permeability to oxygen according to the method recommended by the Rilem was carried out to check the permeability of the concrete to gases. According to the same prepared two cylindrical slices of 150 millimeters in diameter and 50 of height. These slices were cut from the top and the bottom of a test tube of 150 millimeters in diameter and height 300 in order to be able to appreciate possible differences due to compaction in the same test tube. The resulting average values of the essay on test tubes of 3 months of age are shown in Figure 3. According to the method Rilem Cembureau9, the coefficient of permeability to oxygen, should be no more than 3 x 10-16 square meters, which is also true in all cases the results from this trial followed a trend similar to the penetration of water under pressureand the concrete with addition of silica smoke which gave the lower coefficient of permeability.

Pore structure

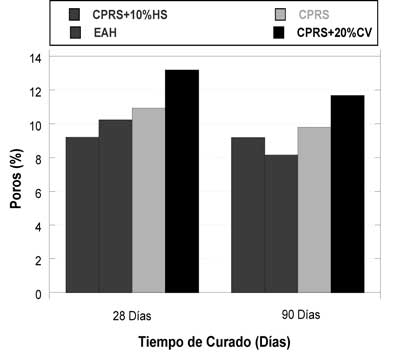

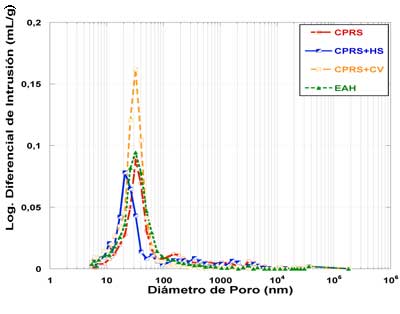

Total porosity, as well as the distribution of pore size has been studied by porosimetría of intrusion of mercury (IPM) in a range from 0.006 to 175 µm, that allows us to evaluate the pores of air and capillaries. The capillary pores have sizes ranging from 30-0, 002 µm [9]. In the upper part of this range, the pores negatively influence the mechanical resistance of the material and durability. The interlaminares pores or gel CSH are children under 18 a, this size is out of the possibility of evaluation with porosímetro of mercury and can only be by isotherms of adsorption-desorption of gases. In any case their presence is not negative or for resistance and the durability of the material.

For the test samples were prepared with a weight of between 2 and 4 grams, which were dried vacuum for degassing the porous structure. These samples were maintained in oven at a temperature of 40 ° C at the time of testing.

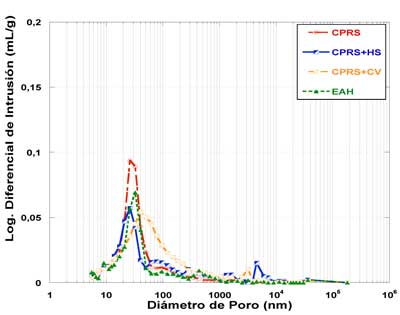

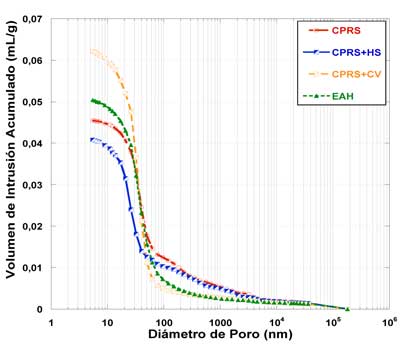

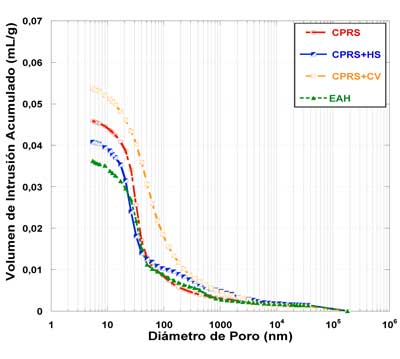

28 And 90 days results are shown in figures 4, 5, 6, 7 and 8 for all types of concrete studied. As you can see, in all cases, by increasing the time of hydration, reduces total porosity, and to the porous distribution moves towards lower values of diameter of the pore medium.

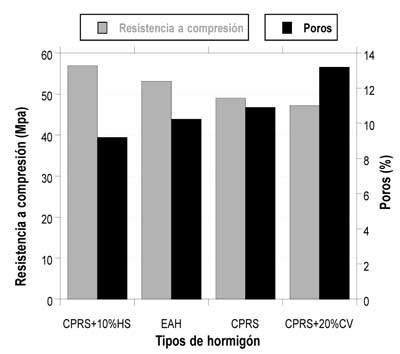

Total porosity, in the dosage containing fly ash, is considerably higher than in all other amasadas. This is due to the delay in the reaction Pozzolanic which is closing the pores over time. The kneaded with addition of silica smoke shows the lower total porosity, along with the smaller diameter of pore in all ages. In Figure 9 relate to the values of the total porosity and resistance to compression to 28 days.

Conclusions

Comparing the results obtained with the various types of concrete used in experimentation, found that the dosage which contains 10% silica smoke has given no doubt better resistance than others. This was expected a priori, however, need to deepen the research of other mechanical characteristics, resistance to traction and modulus of elasticity, which in principle is not so obvious that they will follow the same trend.

The distribution of concrete pore size changes with the type and content of cement, water/cement ratio, type of additives and additions, as well as compaction of concrete. Figures 5 and 6 show the curves of intrusion of mercury of studied mixtures and the derivative of the volume of intrusion on the diameter, respectively. In almost all the mixes (CPRS+10% HS, CPRS and EA), the vast majority of the pores are concentrated in a narrow range of diameters ranging from 6 to 50 nm, 7-95 nm, and 6 and 95 nm respectively, while in the mixture of CPRS+20% CV diameters interval is increased, giving rise to a distribution of pores more wide, ranging between 11 and 120 nm. With the use of silica smoke decreases the volume of intrusion of mercury as seen in figures 5 and 6. This data is consistent with the results of lower permeability to water as gas that have been obtained with the mixture composed of silica smoke. Now can investigate whether this improvement which introduces the smoke of silica is also reflected in greater resistance to chemical attack due to the aggressive present in sea water.

It is important to note that with the smoke of silica is obtained by first ages a very compact structure, which does not suffer significant changes when moving the degree of hydration. It is not true of the other additions where reactions puzolánicas significantly change the pore distribution of the material.

Figure 9 shows the relationship between the total of the material porosity and resistance to compression. In all studied concrete there is a reverse tendency in these variables according to the existing data in the bibliography.

Based on the results achieved to date in the experimental campaign, we can say that both the resistance and the behavior of the concrete to the transport of fluids are determined by the porous structure of the material. This work is included in a larger study which aims to assess the influence of the composition of the concrete from the attack of the ions present in water marina, identifying and evaluating the possible synergies between them. In response to this application and considering that the contact with the aggressive medium occurs within hours of the manufacture of the material it could be summarized the following conclusions:

- Data from all the studied doses show the direct relationship between the capacity of transport of the material and porous distribution thereof.

- The results observed for the studied concretes are grouped into two distinct behaviors. The concretes CPRS and CPRS + 20% CV, presented a similar behavior, lower resistance and greater permeability to fluids. On the other hand the concretes CPRS + 10% HS and EA have also similar behavior, with greater strength and reduced capacity for transport of fluids.

- The coefficient of permeability to the oxygen is more sensitive to characterize different dosages studied on the basis of their ability to transport.

- It is very important to highlight the different evolution of porous distribution with the hydration in concrete studied. A selection based only on the behaviour of the material to 90 days could determine serious damage in durability, allowing the initial penetration of the aggressive.

Thanks

The authors are grateful to the Ministry of development and the Ministry of education and science economic aid granted by MFOM-2004/9 and BIA2005-09250-CO3-02 projects, as well as a FPU scholarship for Safwat Mahmoud Abdelkader.

Bibliography

[1] Shannag, M. j., Hussein, a. S. ' Sulfate resistance of high-performance concrete', Cement & concrete composites, 25, pp. 363-369 (2003).

[2] Lee, S. T., H. y., Swamy, r. b. ' Sulfate attack and role of silica smoke in resisting strength loss', Cement & concrete composites, 27, pp. 65-76, (2005).

[3] Ganjian, e., Pouya, H. ' Effect of magnesium and sulfate ions on durability of silica smoke blended mixes exposed to the tidal zone seawater', Cement and concrete research, 35, pp. 1332-1343 (2005).

[4] Sezer, g., Ramyar, k., Karasu, B., a. B., Sezer, a. ' Image analysis of sulfate attack on hardened cement paste', Materials and Design, 29, pp. 224-231, (2008).

[5] Menéndez, e. ' expansive concrete processes: trials arid-alkali sulphate attack and hielo-deshielo attack. System of prevention and performances ', Institute of science in construction Eduardo Torroja (CSIC), course of study of the construction.

[6] Bermúdez M Á., Alaejos, p. 'Permeability to chlorides of reinforced concrete located in submerged marine environment', engineering construction, 22 No. 1, pp. 15-22 (2007).

[7] EHE-98 'Instruction Spanish structural concrete', Ministry of public works, (1998).

[8] 192 C ASTM ' Making and curing concrete test specimens in the laboratory'.

[9] Lawrence, M. p. 'Influence of two kinds of Spanish fly ash on the microstructure and durability of the hydrated cement paste', Universidad Complutense de Madrid, Faculty of chemical sciences, Spain, (1993).