Cement compacted with roller

The preys of gravity, of armed cement, no longer are fashionable. The cement RCC is more than a new material, is a new method of construction, in which all are advantages: lower consumption of cement, greater resistance, lower time to finish, to top the prey, lower cost. The concept compact the cement to base of a vibratory roller is easy to comprise. The execution no longer is so easy. The same equipment of compactación of the asphaltic cement use them for the RCC, with a static load of 30 kg, as minimum. Finished the compactación begins the fraguado or hydratation of the cement.

The Symposium of Saragossa treated of preys in general. There are a lot of types, and do not refer me to if they are high (generate electrical power) or low, for irrigation. Ones are of gravity, a straight wall with his two slopes bent, that bear the push of the water embalsada. The weight of the prey is sufficient to contain the hydraulics pressesure.

Afterwards there are them of arch, and arch of double curvature, in the vertical plane and in the horizontal (prey of vault). The form of the prey is the attendant to resist the push of the water. The pressesure transfers in shape very concentrated to the right and left extremes of the wall. Slopes that have to be of rock very hard and resistant. They require lower quantity of concrete. Already the Romans did a prey of arch in Glanum, France.

The brick, sillería and manpostería, loose materials, are for the preys of little elevation, that it is necessary impermeabilizar. In Spain have the accident of the Prey of Tous, built with loose materials. On 20 October 1982 derrumbó, because of several failures, in a grown of the rio Júcar. Waters down destroyed part of the population of Alcira. In 1994 it built the new prey, higher, of concrete, that generates electrical power. In Spain 67% of the preys are of gravity, done with concrete, with or without armours of steel. They are the preys of before.

Hydraulics cement and the RCC

Remember what is a mix of clinker: arid, ashes steering wheels and gravel, and when reacting with water (a strong exothermic reaction) solidifies with the cured, fraguado. It increases his consistency and in 27 days will form a mass pétrea. It exists the period of prefraguado, that oscillates between 2 and 4 hours. The hydratation of the cement is indispensable to improve the resistance to the compressesion. The cured humid continuous, wet the cement, from the moment in that it is placed until it has purchased the quality wished. It is possible the immersion of the cement in water, the rociado and the humid covers, arpillera humid, membranes of cured, or provisional formwork, paper Kraft raincoat. The excessive evaporation of water in the recently placed concrete can retardar appreciably the process of hydratation to early age. The loss of water also causes the retracción of the concrete, generating tensions, fissures, in the exposed surface.

Avoid the periodic irrigation with water. The hydratation progresses slowly when the temperature is drop, underneath of the 10°C. The compounds of cured can prevent the adherencia between the cool concrete and the toughened, an important incident when building the prey with RCC. The process of cured has to prolong until the cement have reached, as, minimum, 70% of his resistance of project, usually during some 7 days. But they do fault more if the RCC is of endurecimiento slow. The cured accelerated is possible: it Is the cement of masonry. To build a prey does not serve us, does fault the cement of high resistance.

In the factory of cements calcina the stone, the calcic carbonate, forms CaO, cal alive, and this reacts to his time with silicates, to form calcic silicate. In the same oven, to 1.400 °C, forms aluminato tricálcico and ferroaluminato tetracálcico. To these products call clinker. The necessary power to obtain a gram of clinker is of 1.700 Julies/gram. The cement comports a big demand of power. To the clinker adds him 2% of plaster and the mix is grinded.

In mechanical properties the RCC equivale to the hydraulics cement, but contains less water and greater density, because of the aggregated fine and thickness. They suppose the 75-85% of the total. The RCC contains 12-15% of cement and 4-6% of water, less waters that the C.Hydraulics. The RCC after compacted cures and can attain a high resistance before that the hydraulics cement, if we do use of some ingredients, for example: increase the cement, the density, until 356-593 kg/m3, or diminish the percentage of water until 0,20-0,45%.

The ashes steering wheels, porous, the residue formed when burning lignite (mineral coal), component of the hydraulics cement, also incorporate to the RCC, and equally the slags of high ovens. Of the volcano of Puzuolli, Vesubio (Italy), obtained ashes in the antiquity to add to the cal, the cement. The puzolanas, material aluminium-silíceos, synthetic, added historically to the cement, incorporate to the RCC. His composition is the mix of 3 oxides, of silicon, aluminium and ironinging. Of the volcano of Puzuolli went out lavas ígneas, that when cooling quickly turned into amorphous glass, dust, porous, that is to say, the puzolana. The clinker in the RCC keeps on being the normal, 70% of puzolana (agglutinative minimum) and 30% of cal.

The RCC goes winning with the age in resistance, so much mechanical like chemicals, surpassing to the portland. The aggregated are gravel of until 8 cm of diameter. The ideal percentage of water is 6%, but can arrive until 10%. The additives can do to the most fluent pasta. The compactación are hits of hammer (4,5 kg), that leaves fall from 50 cm of height on the pasta.

The method RCC

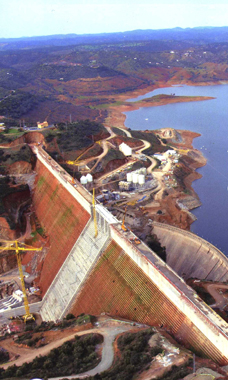

Traces back to 1960 when Taiwan built the prey of Shihmen, afterwards came the prey of Tarbela, Pakistan, and confirms that it is the best method of construction: the cement compacted with vibratory roller, with minor contained of water, precisely to allow the compactación. The content of cement is of the same order that the one of the cements vibrated for paving, between 280 and 330 kg/m3. In the prey superimpose the diverse layers, with unions very cuidar. The method allows greater rapidity, build 2-2,5 m of height of prey by week, shortening the term of execution and using on a large scale dumpers, bulldozers, rollers. The greater part of these preys are straight, are of gravity. The ones of arch do not allow so much rapidity.

From the decade of the 70 the prey RCC has followed 3 concepts: poor mix, mix of half content and high content of pasta.

By poor mix understand 70-100kg/m3 (prey of Wilow Creek, EE.UU). In 1996, Brazil built the prey of Jordao, with 85kg/m3 of conglomerante. The advantage is a lower development of heat during the process of hydratation.

Like prey of half content quote Them Olivettes, France. 130kg/m3 of a special cement.

Like preys of high content of pasta, with dosages of conglomerante between 150 and 270 kg/m3, with a high proportion of ashes steering wheels, can stand out the ones of Upper Stillwater, EE UU (1987) and Rialb, Spain, (2000), with 200 kg/m3. From 1995 the Spanish preys belong to this third group. High heat of hydratation, high density, but waterproof, which indicates that we can do without work adds, for impermeabilizar the walls of the prey. With the method RCC the prey is not easier to build but is something more economic.

The thickness of each layer in the wall of the prey is of 50-100 cm, that compact of an alone time. The new preys of high content of pasta are the most frequent, 47% of the new preys, and all generate electrical power. Of course, the walls are very waterproof to the water. The transversal section of the prey can reduce, even in the zones of seismic activity. The solidez is guaranteeed, with a cement of low content of cal, and to an inferior cost to the of a prey built with the conventional method. The fraguado is slower, less generation of heat in the reaction with the water, heat of hydratation more reduced. It translates in a greater term to compact the material.

The Spanish preys RCC use a lot the ashes steering wheels (with a content of cal low, 35%) because Spain produces to the year some 7 million Tm of ashes steering wheels. The slags granulated of high oven use less. The resistance to the compressesion is of 210-400 kg/cm2 of the probeta. The retracción of the cement is invalid. The percentage of water oscillates between 4-6%. The resistance of the cement RCC entirely consolidated is inversamente proportional to the percentage waters/cement. To world-wide level the greater preys RCC are the one of Longtan, China, 216,5 m of height and the one of High Diamer Basha, Pakistan, 272 m of height.

American Concretise Institute. Roller compacted Mass Concretise. Act 207.5R-99.

Choi, And. RCC mix Design – Soil approach. Journal of materials in Civil engineering. January 2001.

Dunstan, M. Recent developments in RCC Dams. Hydropower & Dams 1999.

Hansen, K. Roller compacted Concretise dams. McGraw Hill, New York 1991.

Rodríguez, F. The Use of roller compacted concretise. Brazil, Sao Paulo 1998.

Santana, J. To geotechnical methodology for roller compacted concretise Design. University Nova of Lisbon, 2007.