The smart alternative to the fork of vibrating plate or fingerboard and other existing systems

January 26, 2011

One of the most common applications in the process industry is the timely registration of the fill level. It monitors the level of material at a specific point (maximum/minimum) or serves as a protection against the sobrellenado or the running dry. For this there is a series of level switches based on different technologies for high. What is the most appropriate technology? Depends on the application area and, therefore, of the requirements of the sector. Therefore, it is necessary to take into account certain factors specific to the application as the formation of foam, the presence of materials highly aggressive or flammable or simply apelmazables, as well as limited conditions of the environment or environment. However, the speed of the process of filling and the required accuracy of the measurement are also important factors in choosing the appropriate measuring instrument.

Disadvantages of vibrating level switches

Often the area of application of level switches is limited because only they can be placed in certain positions in the container or because their little or excessive sensitivity leads to errors of measurement of some media. Even the mechanical composition of a sensor can lead to deficiencies. The most common vibrating level switches have a fork of big vibration that enters the environment to measure the change in frequency of the same, which turns the output of the sensor. This also often produces errors of measurement because the sticky media are attached to the fork. As the forks of vibration is introduced, depending on the version, between five and ten centimeters in the middle are difficult to clean. Longer the fork more prone to suffer mechanical damage and cambering are. Vibrating level switches need also a lot of space outside the container. Even the specific weight of the means to measure may limit the areas of application of the vibration fork, since, for example, resistance of very light media such as the ash may be so small that forks are unable to detect if you want to the environment.

While it is true that vibration fork level switches can be used for relatively many applications, its flexibility is limited, which are necessary versions for liquid substances and in powder form. Measurement methods such as ultrasound sensors or the optical or simply mechanical buoys by flotation also often have a very limited application area.

LBFS - a sensor for all applications: liquids, gases or solids

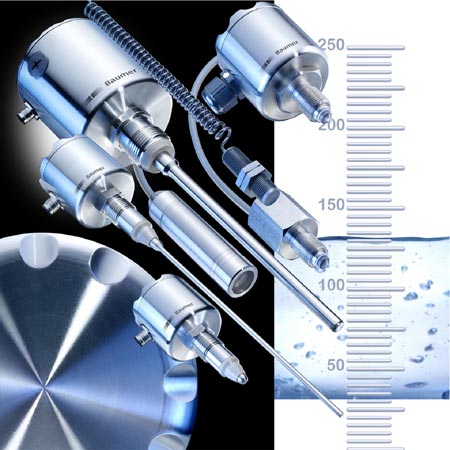

Until now it was hardly possible to cover all types of applications with a single level switch. The new Baumer LBFS level switch covers that gap. It is based on the technology of microwave and its deviation of frequency, which means that the frequency sent by the sensor experiences a change of the phase depending on the particular environment. In contact with a medium with a dielectric constant different from the default it causes an electrical signal. The high sensitivity across a range of measurement for dielectric constants of 1.5 up to 100 can detect all types of powders, granulates and liquids level. Even difficult substances such as polyamide powder or paper are recognized in an effective manner. Against other methods of measurement as a fork of vibration, Ultrasonic sensors, the optical or just flotation buoys, this technology presents decisive advantages: it does not have vibration parts, it is insensitive to changes based on the conductivity, the temperature or pressure and especially fits very easily its sensitivity to discern between different media or products. In addition, the sensor is suitable for all kinds of applications for which until now several types of instruments were needed.

The sensor is housed in a compact housing of stainless steel, especially robust and resistant to corrosion. Is it easy to install and can be sealed for example with a band of Teflon. A brilliant 360 ° LED indicator ensures good visibility of the switching point even if the sensor is installed at the top of the tank. With the help of FlexProgrammer 9701 the LBFS can be configured on the computer. The instrument is suitable for a wide range of temperatures between - 40 ° C and 115 ° C. Or even sticky media are adhered through its compact and smooth head. The function Teach - in allows to adjust the switching point to such difficult media. Also the sensor head gets very little into the means by which can be easily cleaned.

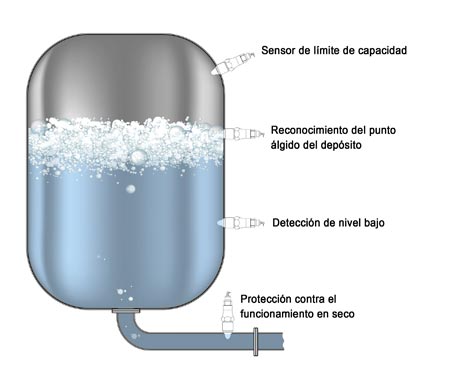

The LBFS recognizes the level in tanks, tanks and pipes. In storage, clearing and filling tanks are usually installed switches to high levels. The short response time adjustable of the LBFS might be of only 0.2 seconds allows rapid filling processes, as well as a rapid and effective detention of filling. The sensor is suitable as a protection of sobrellenado and as bomb protection against running dry, as a detector of interfaces or recognizing one or another product. Progress in vacuum pumps is a critical problem because it can lead to deviations from the dosage or cause damage. Even with viscous or sticky means the LBFS offers reliable protection against the operation in vacuum. In specific processes the environment through different phases. In such cases the phases can be recognized (separation of mixtures of oil and water resources) or ignore (layer of foam) measurement.

The LBFS is available with connections G1/2, G3/4"processes and G1". On request it can be delivered with another type of connection. The State of the switch can be marked as ' normal open ' or ' normal closed '. As output PNP and NPN are available. The sensor corresponds to the type of protection IP67.

Extensive areas of application

Because the LBFS can be used with all means and in close inaccessible spaces, there is a large number of possibilities of application, for example in the following areas: water, waste water, filtration, plastic injection moulding machines, mills of high-performance machines for cleaning the metal, HVAC (heating, ventilation and air conditioning systems), hydraulic, transmission of levels of fluids, oil and gas, pellets of wood, grain mills, transportation rail, bioenergy and systems of pumped.

For applications in the treatment of water level measurement instruments must be particularly robust. This refers on the one hand to the materials used when measuring instruments come in contact with media aggressive or corrosive, such as desalination plants or in the treatment of the mud. Also devices must be very resistant to strong vibrations, such as those that occur in the case of applications with volumetric pumps. Other challenges are the formation of foam, materials in suspension or condensation occurring inside the tank. The LBFS allows this type of applications a recognition of the level of reliable and accurate.

Hygienic version: LFFS

With the exception of hygienic applications the LBFS can be used in all sectors and areas. For the food and beverage industry Baumer offers the equivalent to the LBFS. Switch level LFFS complies with the requirements EHEDG (European Hygienic Engineering and Design Group) and has a 3rd permission. It is suitable for high temperature to 200 ° C (with cooling fin) processes. The LFFS also acknowledges the level of liquids, thick media and dry materials, therefore can be used with many media.