Heavy Metal: special materials for systems with separators

September 2, 2009

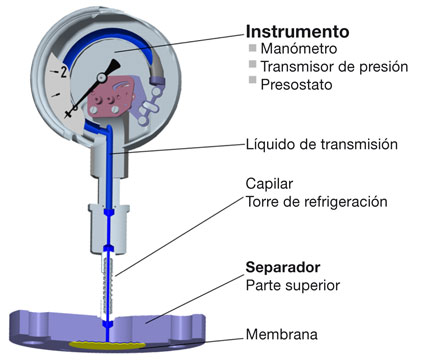

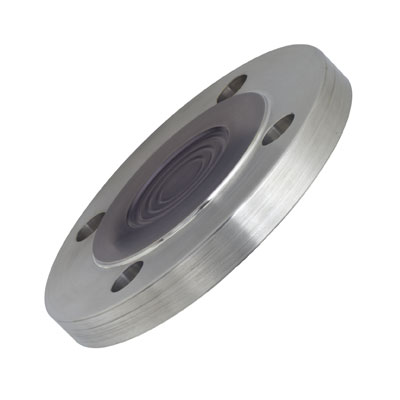

With flange separators allow the adaptation of pressure measuring instruments to the most adverse conditions of the chemical and petrochemical industry. The oldest model, the 990.27, was released 35 years ago and protects several thousand instruments around the world from the effects of aggressive, corrosive, hot or dirty media. The tab system consists of a pressure gauge or a transmitter connected to a separator. The membrane of the separator in direct contact with the process acts on a liquid that hydraulically transmits pressure to the instrument by means of a proportional shift with the variation of the pressure of the process. The connection between instrument and tab can be direct or indirect with hair or a cooling tower.

Materials

Standard membrane material is stainless steel 316 L (1.4404/1.4435). To improve the resistance can cover parts in contact with the medium with PTFE, ECTFE. There is a ceramic covering (wikaramic) against the effects of abrasion.

membranes with materials like tantalum and different varieties of Hastelloy exotic are manufactured for more critical applications. However the implementation of special in combination with high temperatures materials can be problematic. For these cases the entire surface, including the surface of sealing, there must be this exotic material. A membrane of tantalum, welded to a body of 316 L for example, would not be reliable. Applications with negative pressure could cause cracks in the surface sealing with the possible consequence of a rupture of the membrane. In addition there is arguably materials mixed during the welding of the membrane to the body, with more susceptibility to the effects of corrosion from occurring.

Another method of Union would be hitting the membrane to the body with a special adhesive. However this solution is suitable only for applications up to + 150 ° C. In addition you may encounter problems related to the diffusion of gas in the liquid of transmission and the degassing during the evacuation.

Metal Union

The method of the metal Union, patented by Wika, allows the Union of exotic materials such as Hastelloy, Monel and tantalum with the body in stainless steel. This membrane has a Union of surface in the area of across the Board. The metal Union is free of pores and tightness with helium surpasses the 10-9 mbar l/s. This system is suitable for applications with permanent temperatures up to 400 ° C, limited only by the maximum temperature of the fluid transmission and special materials. The user can choose among 20 special different materials, being the most common in chemical and petrochemical applications Hastelloy C4, Hastelloy C276, tantalum, and Monel 400.

Hastelloy C4 and Hastelloy C276 alloys found its application in facilities and processes of the chemical industry. These materials are a good or very good resistance to mineral acids at elevated temperatures, solvents, chlorine and chlorine, acid contamination formica and fermentation media polluted and saline solutions.

Tantalum is noted for its extraordinary resistance against corrosion, comparable with glass and Platinum. This is due to a layer of tantalum pentoxide with strong adhesion to the surface. Monel 400 is resistant against organic and inorganic acids, caustic alkalis and substances salinas. This material is better suited to conditions of reduction of oxidation and is common in marine and petrochemical applications.

Ceramic coating

Wika developed the ceramic coating for aflorante and threaded membrane separators. This coverage provides high protection against abrasion and protects the sensitive membrane of leaching, thereby preventing their rapid wear. An example of application in use with abrasive media is the production of silicone. The base material is silicon in the form of dust and Methyl chloride, and the pressure monitoring is carried out by sandblasting of Silicon. Hastelloy, which presents a high resistance against corrosion, is usually used, but this just like the stainless steel material wears out quickly under these conditions. The implementation of a membrane of Hastelloy with a supplementary ceramic coating provides permanent protection and therefore a significant cost reduction.

Currently Wika produces more than 35,000 separators with diaphragm a year for the application in chemical and petrochemical facilities. Materials and special constructive forms offer effective protection for the instruments to deal with the extreme conditions in the process industry. The wide variety of special materials and constructive ways allow individual adaptation to the specific and adverse conditions of the chemical and petrochemical industry.