Optimisation of processes of purification by means of modules of control standardised

Carlos Merino, responsible of technical support of Process of

Current situation

The environingingmental requirements increasingly restrictivas force to the efficient management of the processes of purification of residual water. The commitment between the quality required of effluent and the adjust of the costs of exploitation only can achieve by means of the introduction of automatic bows of control. The management of the plants of purification of waste water is based usually in systems centralised of PLC (Programmable Logical Controller).

When it pretends implement measures of automation, require usually changes and/or enlargements of the system of PLC of plant. For this needs the manufacturing of specifications, the implementation of algorithms in the PLC, review of his operation, manufacturing of screens of SCADA and documentation associated. These tasks develop with the assistance of external companies, generating significant costs and dilating in the time the profits wished by the automation. In the case of small plants or very ancient, often is necessary to modify the hardware of the PLC and accionamientos of plant, what comports the delay or cancellation in the measures of automation when considering a relation cost/benefit desfavorable.

Modules of control standardised

The modules of control standardised RTC have developed by Hach Lange specifically for his application in the biological waste treatment water, and allow to incorporate concepts of automation to the plants of purification of a fast and economic form. This is particularly useful in plants that lack a department devoted of automation, or do not have of the necessary support for the specification of the algorithms of control. Equally in half plants-big different subprocesos can be automated with modules RTC.

The modules are formulated for his application in specific tasks of automation without modification of the software of plant. Compared with the conventional practice of implementation of algorithms in the PLC, the modules RTC install and put in operation of fast and simple form, achieving immediately the aims of saving. The configuration of the different variables finds integrated in the unit of control of the instrumentation associated, allowing also his sending to the PLC of plant by means of of bus of field, and even his remote transmission by means of GSM/GPRS.

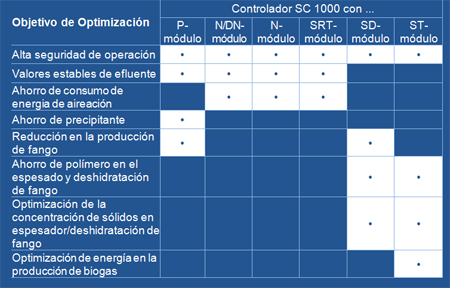

In the actuality are available the following modules of control RTC:

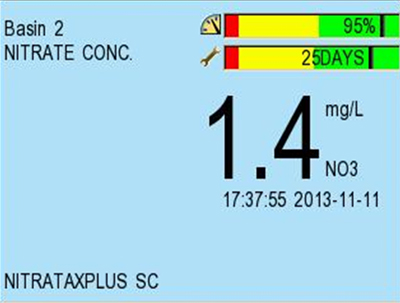

The establishment of systems of control of process demands the utilisation of measurements in real time of the notable variables of the process. The quality of these measurements is fundamental so that the control execute of satisfactory form. To guarantee the correct state of the measurers, Hach Lange has developed Prognosys, a complement of predictive diagnostic that analyses diverse variables and signals of the instrument and provides a visual indication of the state and of the performance of each sensor. Equally it identifies the tasks of maintenance to realizar in the future, determining the remaining time until the following intervention required. The indicator of quality and the indicator of maintenance show like bars coloreadas in the controller of the sensors, identifying of clear form his current situation by measured of his green scale, yellow and red. Pressesing each bar the user will find information detailed of the current situation of each indicator, like the state of calibration, the signals of diagnostic of the sensor, the levels of reagents and other specific readings of the instrument.

All these data allow to speed up the active care of the instrument, the solution of problems and the answer, since the state of the instrument always is visible. The module of control RTC uses equally this information to determine if the measurements of the instrument gather the sufficient reliability to be used in the bow of control. If it is not like this the module RTC raisin of automatic form to work with a strategy of alternative control, substituting the measurement in real time by data of historical profile or sequence of time according to windows previously configured by the user.

Chemical elimination of phosphorus

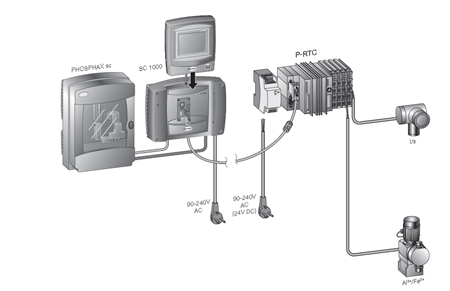

In the process of chemical elimination of phosphorus by means of the addition of metallic salt like ferric chloride or sulphate of alumina, the controller P-RTC (Module of Control of Phosphate in Real Time) allows to realizar the suitable dosage of reactive in base to the current needs of the process, avoiding unnecessary costs and allowing the fast reaction in front of punctual needs of high diet of dosage. In function of the load of phosphate that there is in each case, P-RTC calculates automatically the correct quantity of precipitantes necessary to keep of reliable form the values of necessary exit. On the other hand, when reducing the consumption of precipitantes also minimises the production of slimes, reducing the costs linked to the desiccation and the withdrawal of the same.

Like source of information the system P-RTC uses the measure of ortofosfato in the point of addition of reactive, together with the discharge of the liquor mixes in this point. The measure of ortofosfato realizar by means of the colorimetric analyser Phosphax sc together with the unit of conditioning Filtrax, that extracts a small discharge of permeado of membranes submerged in the point of analysis. The module P-RTC includes algorithms advanced of control that allow his adaptation to any disposal of plant, being able to be configured for his work so much in enclosed bow like open. In the first case the measurement of ortofosfato realizar later to the addition of metallic salt, establishing a double bow PID in base to the concentration of ortofosfato residual and to the current discharge in the point of addition; this control allows fast reactions in front of changes of hydraulics diet of the plant and the confirmation that the process of chemical elimination has realizar properly.

In the case that the installation in bow closed was not possible by the geometry of the plant, is possible the utilisation of the system P-RTC in open bow, with measurement of the concentration of ortofosfato previous to the point of addition of reactive. For this the P-RTC, includes in his internal memory empirical tables of calculation of the stoichiometric relation β metal/ortofosfato for the different types of reagents in function of the need of reduction of ortofosfato, estimating with big precision the discharge required of reactive to keep a level of consign programmable of ortofosfato residual.

Biological elimination of nitrogen

In biological processes with biological reactor with continuous aeration, the module N-RTC allows to establish the concentration of optimum oxygen in function of the following measurements:

- Measured of ammonium to the entrance of reactor óxico by means of probe To-ISE by electrode of selective of ions.

- Measured of solids of the biological reactor by means of probe Solitax.

- Measured of oxygen and temperature of the reactor by means of luminescent probe LDO.

- Measured of ammonium to final of reactor óxico by means of analyser Amtax by selective electrode of gas ammonia.

- Discharge of the reactor óxico.

In base to these measurements the module N-RTC determines by application of model the concentration of optimum oxygen for the load of ammonium to treat in the reactor, readjusting consigns it of oxygen according to the value of concentration obtained to final of treatment with regard to consigns it of ammonium established by the user.

In processes with intermittent aeration, the module N/DN-RTC allows to establish the times of course/stop of the aeration and consigns it optimum of oxygen in function of the measure of the concentration of ammonium and nitrate in the reactor by means of the probe AN-ISE by selective electrode of ions. When limiting the period of aeration to the time demanded by the load of ammonium, can optimise the process of denitrification, reducing considerably the concentration of total nitrogen with an important saving of power.

Treatment of muds

The modules RTC allow also improve the efficiency of the treatment of muds. The module SRT-RTC (Sludge Retention Time) controls the age of the mud monitoring the temperature of the water and the concentration of solids in the tanks of aeration and in the recirculation of mud. The system calculates the age of optimum mud and determines the purge of mud required. This helps to the stability of the nitrification and to diminish the cost of the power of aeration.

The module ST-RTC (Sludge Thickening) allows to control the dosage of polielectrolito in the espesadores dynamic, obtaining a mud thickened stable and with high concentration of solids to the entrance of the digester, what allows to optimise the production of biogás. It uses the measure of the concentration of solids to the entrance and exit of the espesador. Equally, the module SD-RTC (Sludge Dewatering) realizar the adjust of the dosage of polielectrolito to the entrance of centrifuges monitoring the concentration of solids and the discharge, allowing improve the dryness of the mud dehydrated and reduce the costs of reactive.