BASF presents its potential with many new features

Technical plastics

Those who use technical plastics today because no wonder both new materials and solutions to their problems. In these circumstances the technical plastics must be more special, which means that they can be used in fewer applications, but more demanding. BASF has launched a very useful tool of simulation, called Ultrasim, which contributes in good way in the manufacture of deposits of oil, engine parts or structures of protections of sidewalks.

The result of his investigations are new specialties in its range of polyamides and PBT. One of them is Ultramid (PA) that supports high temperatures or the fire-resistant Ultradur (PBT) and coloreable in color clear, without contain halogens.

There are degrees of Ultramid almost as resistant as the metal, without losing the advantages of plastics, and degrees of Ultradur behave perfectly when they welded by laser. The fact that many new names of products, such as Ultramid Structure, Ultradur FRee, Endure Ultramid and Ultradur LUX shows that milestones have been achieved because, as points out Willy Hoven-Nievelstein, director of the Engineering Plastics Europe business unitonly in that case BASF gives its plastic new technical names of brand.

There are many opportunities to the plastics near the engine. With the new degree of specialization of polyamide (PA), Ultramid Endure, BASF researchers have found a way out of the crossroads. This material is a polyamide reinforced with glass fiber that combines an extraordinary resistance to thermal aging with good processing power that characterizes PA 66. Compared with the degree of polyamide PA 66 standard, the processing capacity of Ultramid A3WG7 also has improved significantly.

More substitutions of the metal will occur after the submission of the polyamides of high performance, BASF Ultramid Structure LF long fibers of glass. It's a new group of products of this company, aimed at the replacement of metals. The polyamides reinforced with glass fibres are long opportunities beyond the who arrive the reinforced with short glass fibre.

On the other hand, the range of polyamides 610 of Basf, in the market from the K 2007, has increased with four new materials reinforced with glass fibre: Ultramid S3EG6 Balance, Ultramid S3WG6 and S3WG7 Balance and Ultramid A3HG6 Balance. Its glass fibre content is 30% (G6) and 35% (G7).

Ultramid S balance sheet has lower density and absorbs less moisture than the conventional polyamide 6 and 66. Its great resistance to hot water, steam rupture by tension if exposed to aggressive chemical agents makes it a very competitive material against other polyamides. It emphasizes its resistance to calcium chloride, used in Asia and Russia as salt for the road and the zinc chloride which can form in the car.

The three new degrees of Ultramid S balance sheet can be used for the sobremoldeo of metal components and electronics.

In the field of the products Ultramid another novelty is the improvement of the flow properties. After improving them in the PBT - Ultradur High Speed - and in varying degrees of PA 66 - Ultramid A High Speed - BASF has completed the family with new compounds of PA 6 high speed. The first degree is the B3WG6 Ultramid High Speed, flowing at least a 50% faster than its conventional predecessor, with a thickness of flow in a spiral of 2.5 mm.

Films

Ago three years were presented to the market based on Styrolux HS 70 shrink films, completely settled already in the European market of the labels 'sleeve' type. Against the conventional mixture of SBC (styrene butadiene block copolymer) and PS (polystyrene) this material stands out for its high contraction of more than 70%. Now has been a step further, with a concept of two components which differs from the already mentioned: it's Styrolux T (by 'toughness' - tenacity) and Styrolux S ('stiffness - rigidity). Films made of Styrolux T/S are very transparent and bright and are particularly suitable for cross-sectional drawing, as well as the Styrolux HS 70 technology. This technology allows tag through shrink technology 'sleeve' and achieve various label forms and unusual designs.

These new materials are also suitable for drawing of the films in the direction of the extrusion (MD, by 'machine direction') technology, a more simple labelling technology from the point of view of the machine that is needed.

Foams

The history of Basf with polymeric foams began in 1952 with the invention of Styropor (EPS: expandable polystyrene). Today offers panels from rigid polystyrene foam extruded (XPS), the range of polyolefin Styrodur elastic and resistant Neopolen, the resin foam Basotect layer and the advanced version of EPS thermal insulation Neopor.

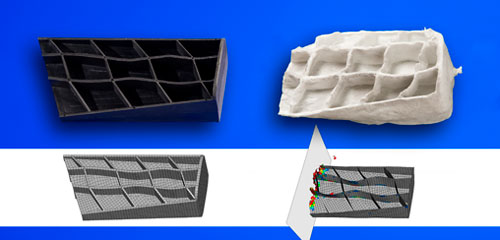

In this edition of the K, is again a new innovation: E-on is a material which not only relies on a new formula, but which is also manufactured using a new process of production. E-on is the first foam elastic and resistant, resistant to the supervises, which can be transported, stored, processed and recycled as the traditional Styropor. The material is characterized by a great fusion of the surface, excellent resistance to solvents and an attractive look and feel. Thanks to its high resistance to the supervises it stable against multiple shocks, and is therefore ideal for use as packaging for the transport of sensitive electronic and electrical products to impacts, such as plasma televisions, laptopshousehold refrigerators and washing machines. Thanks to its special profile properties, new BASF granules offer advantages throughout the entire chain of value for packaging that is used in transport: from the processor, the manufacturer of the equipment and the seller, to the same consumer.

Flame retardant plastics

BASF launches new grades of retardant with Ultramid FRee and Ultradur FRee product lines PA and PBT. FRee ('Flame Retardant and Electrical/Electronic') grades are formulated with halogen-free flame retardants and are ideal for electronic components in any color, due to their soft natural color.

The lower grades are presented in the K: Ultramid FRee A3U40 G5, based on PA66, which complies with IEC 60335-1 safety in electrical appliances, and Ultramid FRee B3U31 G4, based on a PA 6. The line of PBT has expanded with the degree Ultradur FRee B4440 G5 and G5 B4450.

Improvement of welding of PBT

Experts are in agreement that the PBT can not be well laser, but BASF contradicts this standard with the new Ultradur LUX, which has increased its transparency to the laser from 30% to 60%. Achievable speeds of 10-70 mm per second. Greater transparency not only laser speeds up, but it also allows to weld thicker pieces.

Medicine

A technical plastic from BASF help in the future to avoid breakage in the crossed ligament operations. The handle of a new instrument of the company Resoimplant to insert implants ligaments Crusaders is Ultraform Pro, a copolymer POM semicristalino.

Other innovations are aimed at improving the properties of plastics. For example, in complex applications of technical plastics scarce Orange pigments. Sicopal Orange k 2430, or aggressive chemical agents, or high temperatures.

Po other side, Terblend N already is known because it provides smooth surfaces without the need of painting. Now the novelty Terblend N BX 13043, the first mix of ASA/PA of BASF.

Also new the absorbent UV, CGX grape 006, with more absorption than the predecessor and more resistance in applications such as greenhouses, roofs of shopping centres and similar.