This news article was originally written in Spanish. It has been automatically translated for your convenience. Reasonable efforts have been made to provide an accurate translation, however, no automated translation is perfect nor is it intended to replace a human translator. The original article in Spanish can be viewed at

Coperion presenta el nuevo alimentador FET en la K 2010Coperion: Building 14, stand B33

Coperion presents the new FET feeder at the K 2010

Drafting Interempresas15/09/2010

To achieve a significant increase in the capacity of food materials in powder extrusion machines of double spindle,

coperion gmbh, before Werner & Pfleiderer, has developed the so-called Feed Enhancement Technology (FET). Its basic principle is as follows: the feeding ground is equipped with a porous and permeable wall gas to which applies a vacuum externally. Intermediate air particles absorb powder materials through this section. This compaction of loose material increases the capacity of power of two to three at the same time that the high quality of the product remains unchanged. In addition, presented in the K granulators and pumps for mass cast for high-capacity plants. In fact, visitors will see the largest die under the water in the world.

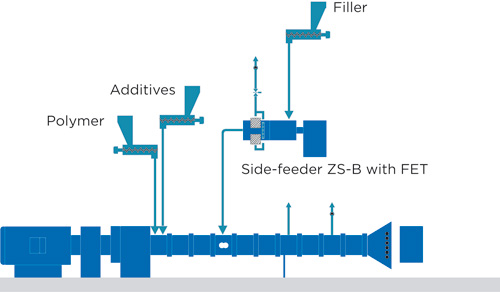

New FET technology is ideal not only for the double spindle ZSK extruder feeding area, but that is also for the side feeder ZS-B double spindle which adds material in powder form directly in the molten mass. Coperion will display at the booth of the K a feeder side A ZS-B double spindle with FET.

Typical arrangement of line of compounding with extruder of double spindle ZSK in which the side feeder ZS-B double spindle is equipped with technology FET.

The main advantages of FET for limited food compounds processes include:

- Low cost of investment, because a smaller unit of compounding can provide the required performance.

- Lower power consumption

- Lower costs of production through the use of loads not coompactadas, cheaper.

- Improving the quality of the compound by a defendant more careful of products sensitive, due to the increased use of the volume of processing available.

- Lower levels of waste, the rear ventilation is not necessary.

- Improves the security of the process thanks to a larger processing window in with regard it to the boundary of the area of food.

FET system in a lateral feeder ZS-B double spindle.

FET, success in numerous applications

The FET system has been tested in numerous new Coperion machines since its launch to the market. In addition, in close collaboration with engineering of process plants, Coperion has made improvements to achieve greater production capacity.

For example, a FET system was installed in an extruder with double spindle ZSK with a diameter of 240 mm for the transformation of polyamide powder. This increased the performance of 14 to 17 t/h, which means a 20% improvement.

Borealis uses at its headquarters in Linz (Austria) a very fine powder, for the production of compounds reinforced with talc. With the help of the FET, it was possible to increase performance up to 200% and eliminate economic bottleneck. Another manufacturer of compounds reached a significant increase in benefits thanks to FET with a ZSK 92.

With 20% of talc (by weight) yields increased from 2.4 to 3.3 t/h, which is a 40% improvement.

Intensive tests developed in a ZSK 40 and a 50 ZSK with varying degrees of talc, achieved improvements up to 300%. Other successes were also possible with other additives: Essays in a ZSK 40 resulted in a performance improvement of 55% with flame retardants and up to 200% graphite.

Die under water: breaking the barrier of 100 t/h

Without a doubt one of the machines that will get the attention of the visitor will be the plate of UG 1.25, the largest die of water in the world. It consists of an average cut of 1,250 mm in diameter and may have even 11,000 drills. The new machine allows capacity for production of more than 100 t/h with PE and rates of flow of water from up to 1,500 m³/h. The elements of hydraulic control and drive system are based on a technology proven over many years in other machines. Since 2009 he is already in operation a model similar to but smaller than for pp.

The largest die of water in the world.

Bombs of mass melted up to 65 t/h of polyolefins

Coperion already presented the first bombs of molten mass of own manufacture at the K 2007. Following the success of installation of numerous machines of this type, in many cases more than three years, in the edition of the 2010 K, Coperion presents the new bombs of molten mass MP 450, which reaches a production capacity of up to 65 t/h. One of these models is currently in the final stages of installation. Transforming polypropylene covers a range of capacities from 30 to 50 t/h.

Great melt pump, model 450 MP.