KDI: Matrimonio de vanguardia en la relación entre motor y máquina

28 de octubre de 2011

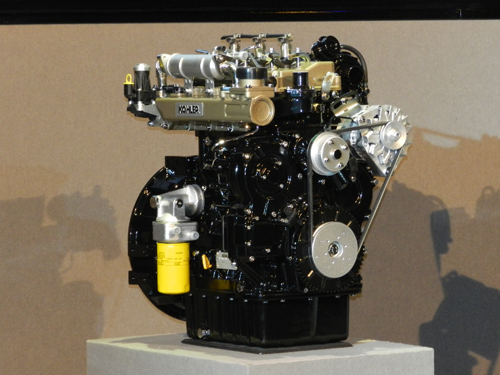

“Un made in Italy, listo para conquistar el mundo”. De esta forma definía Gianni Borghi, presidente del Grupo Lombardini, la nueva gama de motores diésel KDI, que fue presentada puntualmente a las 6 de la tarde del pasado 25 de octubre en un espectacular acto que pudo ser presenciado no sólo por los responsables de la prensa internacional invitados por la firma italiana, sino también por todo aquel que lo deseara en cualquier parte del mundo, a través del servicio online ‘live streaming’ que la empresa empleó por primera vez.

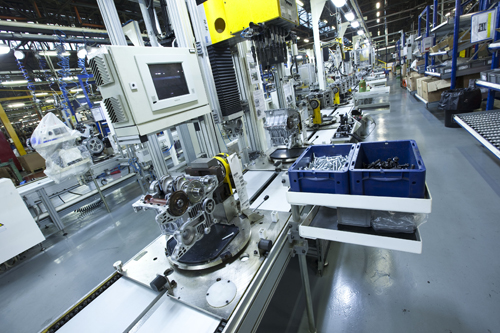

Esta familia de motores es fruto de la fuerte apuesta innovadora que mantiene Lombardini durante sus más de 75 años de historia. “A pesar de la crisis que vive la economía desde el año 2008, Lombardini ha podido realizar inversiones importantes, necesarias para el desarrollo de estos nuevos motores con tecnología de vanguardia, motores excepcionales proyectados completamente por el equipo de I+D de Lombardini que se fabricarán aquí, en nuestra fábrica principal en Reggio Emilia”, continuaba Gianni Borghi.

Esta estrategia innovadora se plasma en los más de 30 millones de euros que Kohler Co., propietario de Lombardini, ha invertido en el desarrollo de este proyecto, iniciado en el año 2009 y que tendrá su siguiente fase destacada en septiembre de 2012, cuando los motores de 1,9 l y 2,5 l pasen a la línea de producción.

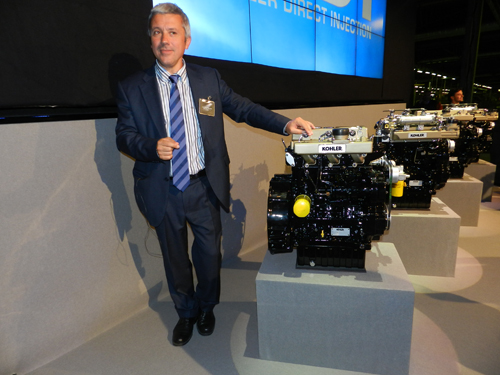

Es precisamente esa confianza en Lombardini por parte de Kohler, como señalaba Giuseppe Bava, director general de la compañía, la que ha hecho posible el nacimiento de esta nueva familia. “Hoy, es un orgullo poder presentar el resultado tangible de la gran confianza que Kohler ha demostrado en el futuro de la industria del diésel y en el talento y capacidades del equipo Lombardini”, indicaba.

El motor KDI ha sido desarrollado por una plataforma de trabajo multifuncional que ha implementado toda su experiencia, desde las compras hasta las líneas de montaje. En total, 25 especialistas, entre ingenieros y proyectistas, han permitido presentar esta nueva gama en un tiempo récord de 24 meses.

Motores limpios

El origen de estos motores hay que buscarlo precisamente en un planteamiento de futuro. El 1 de enero de 2013 entran en vigor las nuevas normativas de emisiones para motores diésel con potencias desde 19 hasta 56 kW en Estados Unidos, y desde 37 hasta 56 kW en Europa.

“Los límites de emisiones previstos por estas normas son tan bajos y restrictivos que cambiarán para siempre el escenario tecnológico de los motores diésel industriales que funcionan en estas franjas de potencias”, manifestaba Francesca Rubbiani, directora de Marketing de Lombardini.

Para afrontar este desafío, la innovación es el denominador común de estos motores completamente nuevos, que se distinguen por el empleo de una tecnología extremadamente a la vanguardia, que permite una combustión limpia limitando las emisiones, sin utilizar ningún sistema de post-tratamiento y que, al mismo tiempo, garantiza prestaciones extraordinarias. Los valores excelentes de potencia y par con relación a las dimensiones reducidas y la ausencia de sistemas para reducir las emisiones, como el DPF, se traducen en ventajas para todos los OEM (Original Equipment Manufacturer / Fabricantes de Maquinaria) que pueden sustituir sus versiones actuales por motores de cilindrada inferior y que, al no tener que ocuparse del proceso de regeneración, les permite reducir consumos y alargar los intervalos de mantenimiento.

“Desde el principio nos hemos preocupado por entender y analizar las exigencias de nuestros clientes, sin limitar este análisis a nuestra actual cartera de clientes, sino incluyendo también a otros fabricantes líderes en Europa y América en los diferentes segmentos del mercado que nos atañen (…) y nuestra respuesta ha sido la innovación”, continuaba Francesca Rubbiani.

Innovando el futuro

El proyecto, muy centrado en las demandas del mercado, fue desarrollado utilizando el nivel más alto de tecnología existente. Una combustión limpia, realizada gracias a un sistema de inyección 'Common Rail' de alta presión (2.000 bar) de última generación, equipado con la válvula EGR (controlada electrónicamente), para la recirculación de la cantidad correcta de gases de combustión enfriados por líquido a través de un intercambiador agua/aire, permite conseguir la conformidad con los niveles de emisión al mismo tiempo que prestaciones únicas sin utilizar sistemas de post-tratamiento.

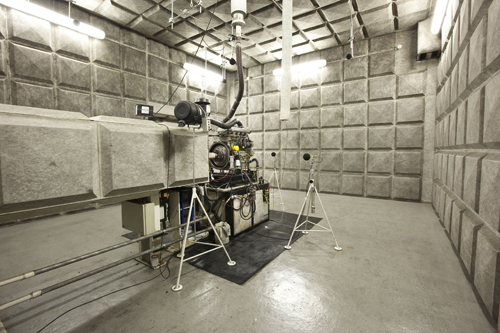

El valor añadido del KDI y de las selecciones tecnológicas efectuadas para realizarlo se traducen, para los usuarios finales, en un mayor confort, por lo compacto que resulta ser el motor, por sus prestaciones, por su robustez y por los bajos niveles de emisión, tanto en términos de vibración como en cuanto al ruido, y en un bajo coste de funcionamiento, con mayor eficiencia en los consumos, usos y mantenimientos.

“Para nosotros la solución más simple para hacer frente a las nuevas normativas de emisiones hubiera sido usar un filtro DPF en los motores existentes pero considerábamos que este sistema presenta varios inconvenientes: el DPF se atasca (hay que limpiarlo y regenerarlo periódicamente), repercute negativamente en el ahorro de combustible, aumenta la reflexión de calor, incrementa las dimensiones totales del motor y, finalmente, es muy caro”, argumentaba Giuseppe Duri, director técnico de Lombardini.

Por todo ello la compañía ha seleccionado el sistema 'Common-Rail' más avanzado del mercado, diseñado específicamente para una extremada duración y resistencia a las condiciones de uso más difíciles, típicas de las aplicaciones en los sectores industriales y de la construcción. La bomba de alta presión permite alcanzar los 2000 bar. Esto, junto con los inyectores con solenoide G3S, permite dosificar de manera excelente el combustible durante el proceso de inyección.

La distribución con 4 válvulas por cilindro ha sido diseñada para alojar el inyector de manera perfectamente vertical y centrado con respecto a la cámara de combustión. Esta solución permite optimizar el llenado, la atomización del combustible y su mezcla con el oxígeno presente en la cámara de combustión.

El colector de admisión y la cámara de combustión han sido desarrollados gracias a un detenido análisis fluido-dinámico (CFD Analysis) a fin de tener una combustión eficiente.

Aplicaciones 'heavy duty'

El turbocompresor con válvula 'waste-gate' ha sido calibrado perfectamente a fin de reducir cualquier retraso de respuesta, garantizando una erogación armoniosa de par y potencia, mejorando el confort del usuario. El gran caudal del aire y el empleo del 'intercooler' contribuyen a lograr los niveles de emisión consentidos y altas prestaciones de par a bajas revoluciones.

El turbocompresor adopta así mismo soluciones técnicas especiales de lubricación y retención del aceite para garantizar el funcionamiento y la fiabilidad con el paso del tiempo.

El sistema de recirculación de los gases de escape, fruto de un detenido análisis CFD, se compone de dos etapas de refrigeración que permiten optimizar el intercambio térmico sin penalizar las dimensiones. Además, el posicionamiento en el lado caliente, previene cualquier bloqueo de la válvula EGR, garantizando de esta forma la máxima fiabilidad.

El sistema de inyección 'Common Rail' junto con la centralita electrónica necesaria para gestionarlo, son los dos de última generación y han sido desarrollados expresamente para equipar las aplicaciones 'heavy duty' en el sector industrial y de la construcción.

La centralita ofrece un control total de los parámetros de calibración del motor para obtener las prestaciones y los niveles de emisión. El sistema Can-bus ofrece una interfaz de comunicación directa entre el motor y todos los aparatos electrónicos de la aplicación.

Ventajas competitivas

“El sistema 'Common Rail' de alta presión (2.000 bar) de última generación (capaz de producir inyecciones múltiples controladas por una centralita electrónica) y la válvula EGR accionada electrónicamente, que hace recircular la cantidad correcta de gases de escape, permiten obtener niveles de emisión conformes a las nuevas normas, proporcionando al mismo tiempo excelentes prestaciones sin utilizar sistemas de post-tratamiento”, señalaba Massimiliano Bonanni, responsable de los motores refrigerados por líquido en Lombardini.

El motor KDI está pensado para ser compacto pero con una gran capacidad de prestaciones (potencia, hasta 23 kW/l; y par, hasta 120 Nm/l). La ausencia del proceso de regeneración reduce los consumos de combustible entre el 3% y el 5%, si se compara con una solución de inyección electrónica de media presión (1600 bar) más DPF; más del 10%, si se compara con una solución de inyección directa y DPF autónomo– como también de aceite. En el consumo de aceite también repercute el alisado especial de los cilindros, realizado con maquinaria de última generación que, permitiendo una reducción de las fricciones, optimiza los consumos y lleva los intervalos de mantenimiento a 500 horas, con una mejora que va desde las 250 horas (comparando KDI con motores actuales no conformes a las normas TIER IV final) hasta las 350 horas (suponiendo su consumo de aceite con DPF).

Además, en los intervalos de mantenimiento no repercute la necesidad de sustituir el filtro antiparticulado (ciclo de vida estimado en unas 3.000 horas). El enfriamiento de los gases de escape recirculados, y el consiguiente abatimiento de los valores de NOx, está garantizado por el posicionamiento de la válvula EGR en el lado caliente, pero, sobre todo, por el recorrido especial seguido por el aire a través de dos etapas de refrigeración. También la geometría particular del colector de admisión permite lograr una mezcla uniforme del aire en cada cilindro, distribuyendo igualmente el abatimiento de NOx logrado por la etapa precedente. Un detenido y cuidadoso análisis de ruido, vibración y severidad (NVH, Noise – Vibration – Harshness) junto con el concepto de “arquitectura de bancada”, es decir una bancada obtenida uniendo dos partes (bancada y sub-bancada) hace que el motor sea robusto, con una estructura rígida, lo cual conlleva menos ruido y menos vibraciones. Las tomas auxiliares de movimiento están diseñadas y situadas de manera tal que ofrezcan el más alto porcentaje de energía desarrollada por el motor. Permiten instalar hasta un grupo de dos bombas hidráulicas en tándem. Además, la relación de rotación de las tomas de fuerza (1:1,2) permite utilizar bombas hidráulicas de menor tamaño garantizando las mismas potencias.

Gama KDI

La nueva familia de motores de inyección directa está disponible en tres diferentes cilindradas, 1,9L, 2,5L y 3,4L, ofreciendo dos configuraciones:

- Inyección mecánica: conforme a las normas de emisión Tier 3/Stage IIIA.

- Inyección 'Common Rail': conforme a las normas de emisión Tier 4/Stage IIIB.

Los motores KDI 3404, para cuya producción habrá que esperar hasta finales de 2014, permitirán expandir el rango de potencias hasta los 100 kW. En cuanto a los motores KDI 1903 y KDI 2504, para una gama de potencias de 31 a 55,4 kW, su fabricación está prevista para septiembre de 2012.

Kohler, una de las empresas privadas más grandes de Estados Unidos, afincada en el estado de Wisconsin, extiende sus actividades a numerosos sectores, desde los motores de gasolina a los grupos electrógenos, desde la cerámica al mobiliario, desde las cadenas hoteleras a los campos de golf. En la división de energía, denominada Global Power Group, entra en el año 2007 Lombardini, tercera empresa a nivel mundial y con una sólida presencia en su segmento de referencia (motores diésel de hasta 50 kW). Desde entonces, han sido muchas y diversas las sinergias surgidas entre ambas compañías. Kohler produce y distribuye, a nivel mundial, motores de gasolina, mono y bicilíndricos, que abarcan potencias de hasta 30,0 kW. Es uno de los nombres más conocidos en el mercado estadounidense por sus motores utilizados en numerosas aplicaciones, sobre todo en el sector 'Lawn and Garden'.

Por su parte, Lombardini fabrica y distribuye motores diésel, mono y multicilíndricos, abarcando una gama que llega a 50kW (en un futuro, hasta 100 kW), equipando máquinas para varios sectores (agricultura, industrial, eléctrico, construcciones, automovilístico y marítimo).

La fuerte presencia de cada empresa en su propio mercado de referencia, Kohler en Estados Unidos, y Lombardini en Europa con cuatro sucursales comerciales en Francia, España, Alemania y Reino Unido, junto con el interés por los mercados en vías de desarrollo, sienta las bases para una difusión capilar del nuevo producto a nivel mundial.

WOC (Las Vegas, 24-27 enero 2012)

ARA (New Orleans, 6-8 febrero 2012)

Hire Show (Coventry, 8-9 febrero)

Fima (Zaragoza, 14-18 febrero)

Golf (Las Vegas, 29 febrero – 1 marzo 2012)

Intermat (París, 16-21 abril)

Galabau (Nürnberg, 12-15 septiembre)

Eima (Bologna, 10-14 noviembre)